| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 5023064 | Materials & Design | 2018 | 11 Pages |

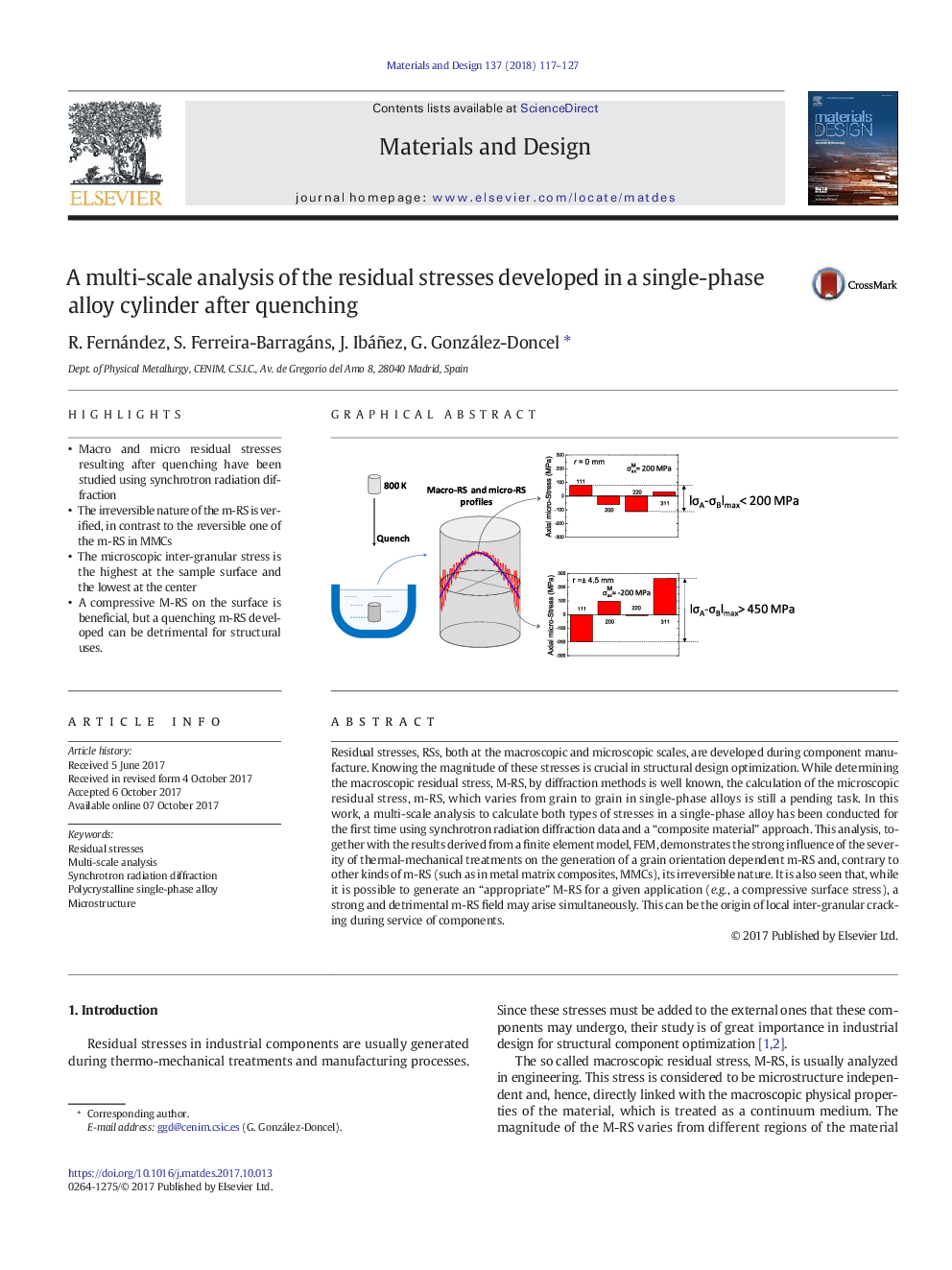

â¢Macro and micro residual stresses resulting after quenching have been studied using synchrotron radiation diffractionâ¢The irreversible nature of the m-RS is verified, in contrast to the reversible one of the m-RS in MMCsâ¢The microscopic inter-granular stress is the highest at the sample surface and the lowest at the centerâ¢A compressive M-RS on the surface is beneficial, but a quenching m-RS developed can be detrimental for structural uses.

Residual stresses, RSs, both at the macroscopic and microscopic scales, are developed during component manufacture. Knowing the magnitude of these stresses is crucial in structural design optimization. While determining the macroscopic residual stress, M-RS, by diffraction methods is well known, the calculation of the microscopic residual stress, m-RS, which varies from grain to grain in single-phase alloys is still a pending task. In this work, a multi-scale analysis to calculate both types of stresses in a single-phase alloy has been conducted for the first time using synchrotron radiation diffraction data and a “composite material” approach. This analysis, together with the results derived from a finite element model, FEM, demonstrates the strong influence of the severity of thermal-mechanical treatments on the generation of a grain orientation dependent m-RS and, contrary to other kinds of m-RS (such as in metal matrix composites, MMCs), its irreversible nature. It is also seen that, while it is possible to generate an “appropriate” M-RS for a given application (e.g., a compressive surface stress), a strong and detrimental m-RS field may arise simultaneously. This can be the origin of local inter-granular cracking during service of components.

Graphical abstractDownload high-res image (178KB)Download full-size image