| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 5023065 | Materials & Design | 2018 | 12 Pages |

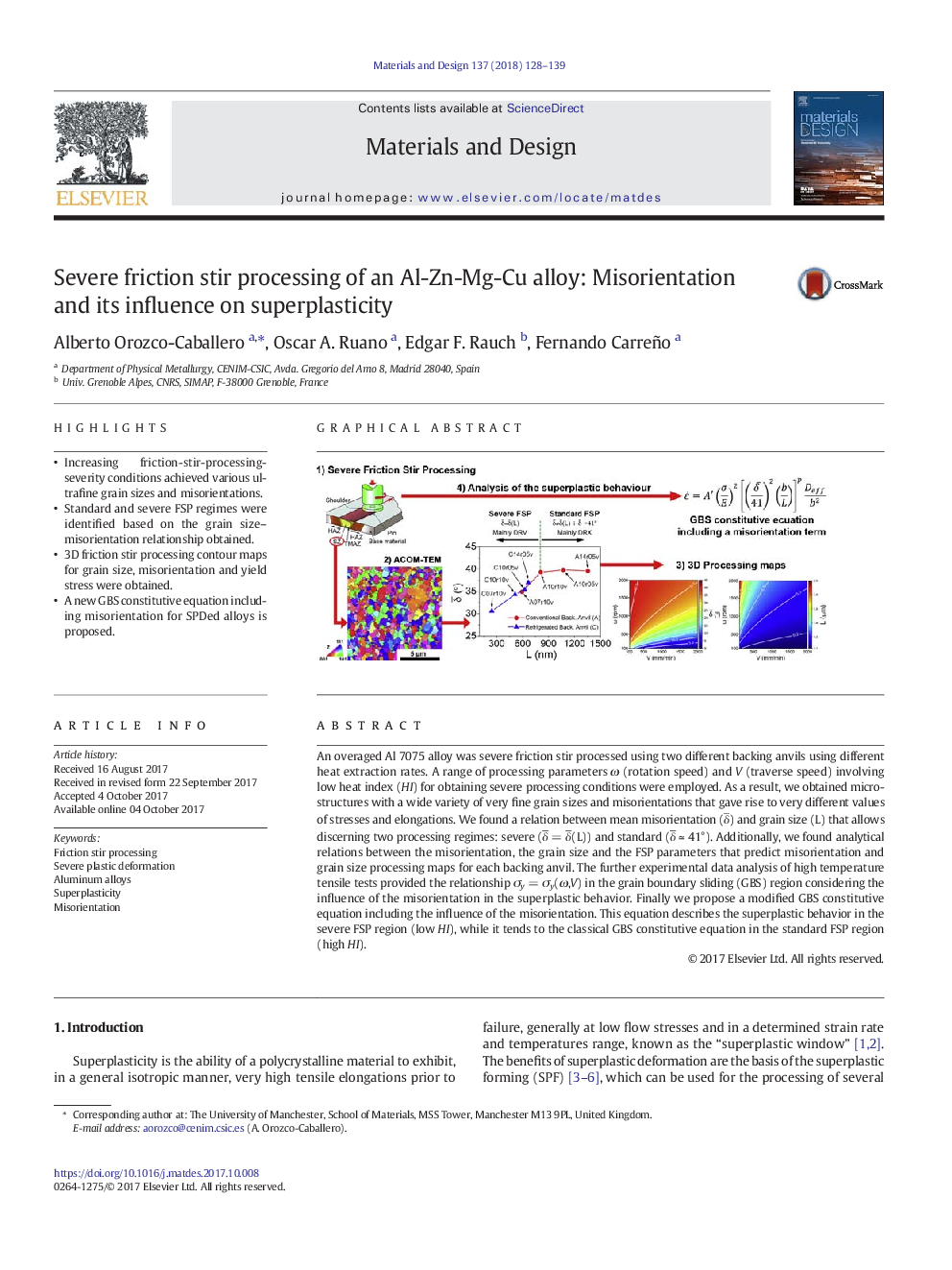

â¢Increasing friction-stir-processing-severity conditions achieved various ultrafine grain sizes and misorientations.â¢Standard and severe FSP regimes were identified based on the grain size-misorientation relationship obtained.â¢3D friction stir processing contour maps for grain size, misorientation and yield stress were obtained.â¢A new GBS constitutive equation including misorientation for SPDed alloys is proposed.

An overaged Al 7075 alloy was severe friction stir processed using two different backing anvils using different heat extraction rates. A range of processing parameters Ï (rotation speed) and V (traverse speed) involving low heat index (HI) for obtaining severe processing conditions were employed. As a result, we obtained microstructures with a wide variety of very fine grain sizes and misorientations that gave rise to very different values of stresses and elongations. We found a relation between mean misorientation (δ¯) and grain size (L) that allows discerning two processing regimes: severe (δ¯= δ¯(L)) and standard (δ¯ â 41°). Additionally, we found analytical relations between the misorientation, the grain size and the FSP parameters that predict misorientation and grain size processing maps for each backing anvil. The further experimental data analysis of high temperature tensile tests provided the relationship Ïy = Ïy(Ï,V) in the grain boundary sliding (GBS) region considering the influence of the misorientation in the superplastic behavior. Finally we propose a modified GBS constitutive equation including the influence of the misorientation. This equation describes the superplastic behavior in the severe FSP region (low HI), while it tends to the classical GBS constitutive equation in the standard FSP region (high HI).

Graphical abstractDownload high-res image (427KB)Download full-size image