| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 5023073 | Materials & Design | 2018 | 12 Pages |

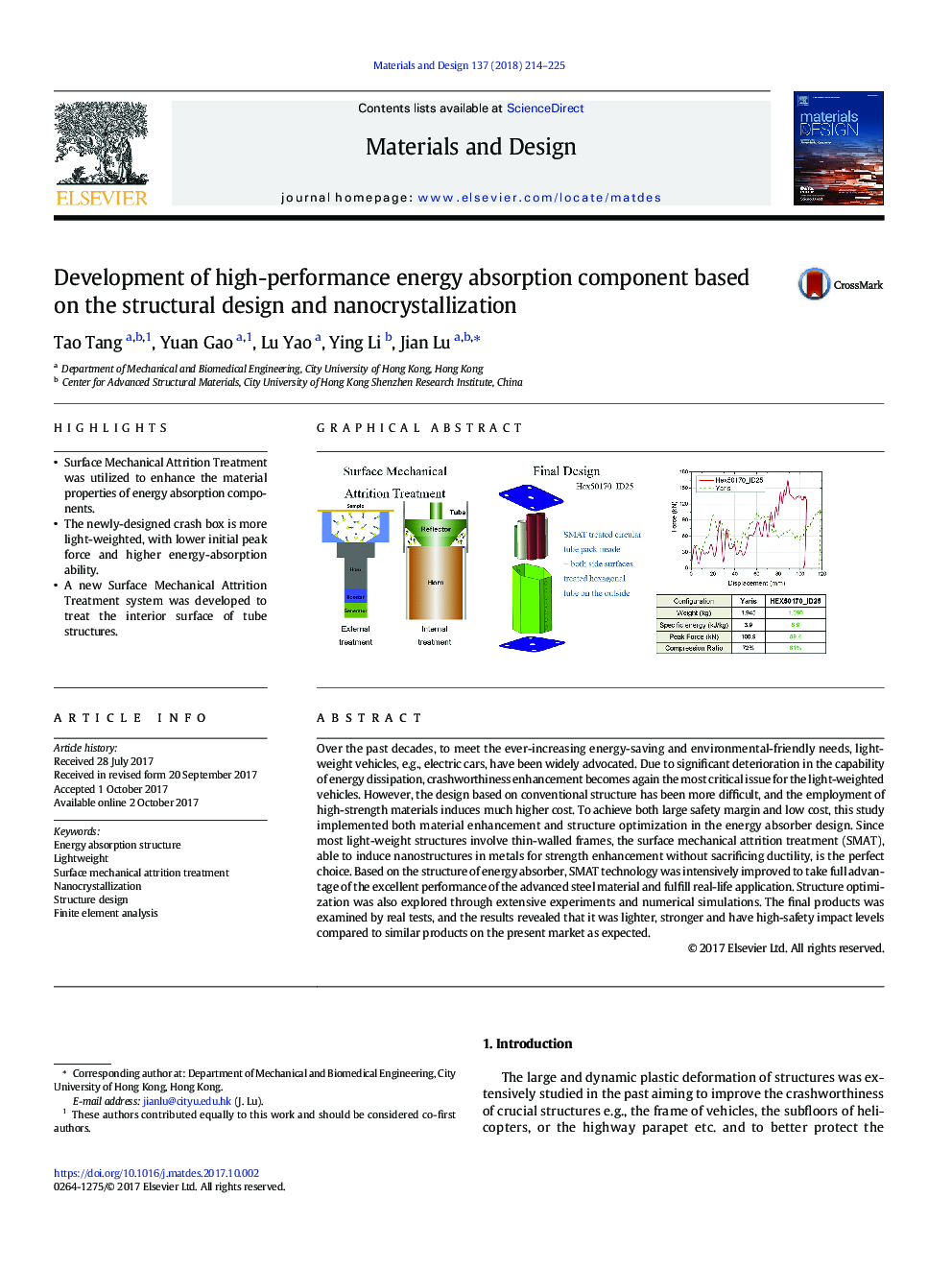

â¢Surface Mechanical Attrition Treatment was utilized to enhance the material properties of energy absorption components.â¢The newly-designed crash box is more light-weighted, with lower initial peak force and higher energy-absorption ability.â¢A new Surface Mechanical Attrition Treatment system was developed to treat the interior surface of tube structures.

Over the past decades, to meet the ever-increasing energy-saving and environmental-friendly needs, light-weight vehicles, e.g., electric cars, have been widely advocated. Due to significant deterioration in the capability of energy dissipation, crashworthiness enhancement becomes again the most critical issue for the light-weighted vehicles. However, the design based on conventional structure has been more difficult, and the employment of high-strength materials induces much higher cost. To achieve both large safety margin and low cost, this study implemented both material enhancement and structure optimization in the energy absorber design. Since most light-weight structures involve thin-walled frames, the surface mechanical attrition treatment (SMAT), able to induce nanostructures in metals for strength enhancement without sacrificing ductility, is the perfect choice. Based on the structure of energy absorber, SMAT technology was intensively improved to take full advantage of the excellent performance of the advanced steel material and fulfill real-life application. Structure optimization was also explored through extensive experiments and numerical simulations. The final products was examined by real tests, and the results revealed that it was lighter, stronger and have high-safety impact levels compared to similar products on the present market as expected.

Graphical abstractDownload high-res image (146KB)Download full-size image