| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 5029062 | Procedia Engineering | 2017 | 5 Pages |

Abstract

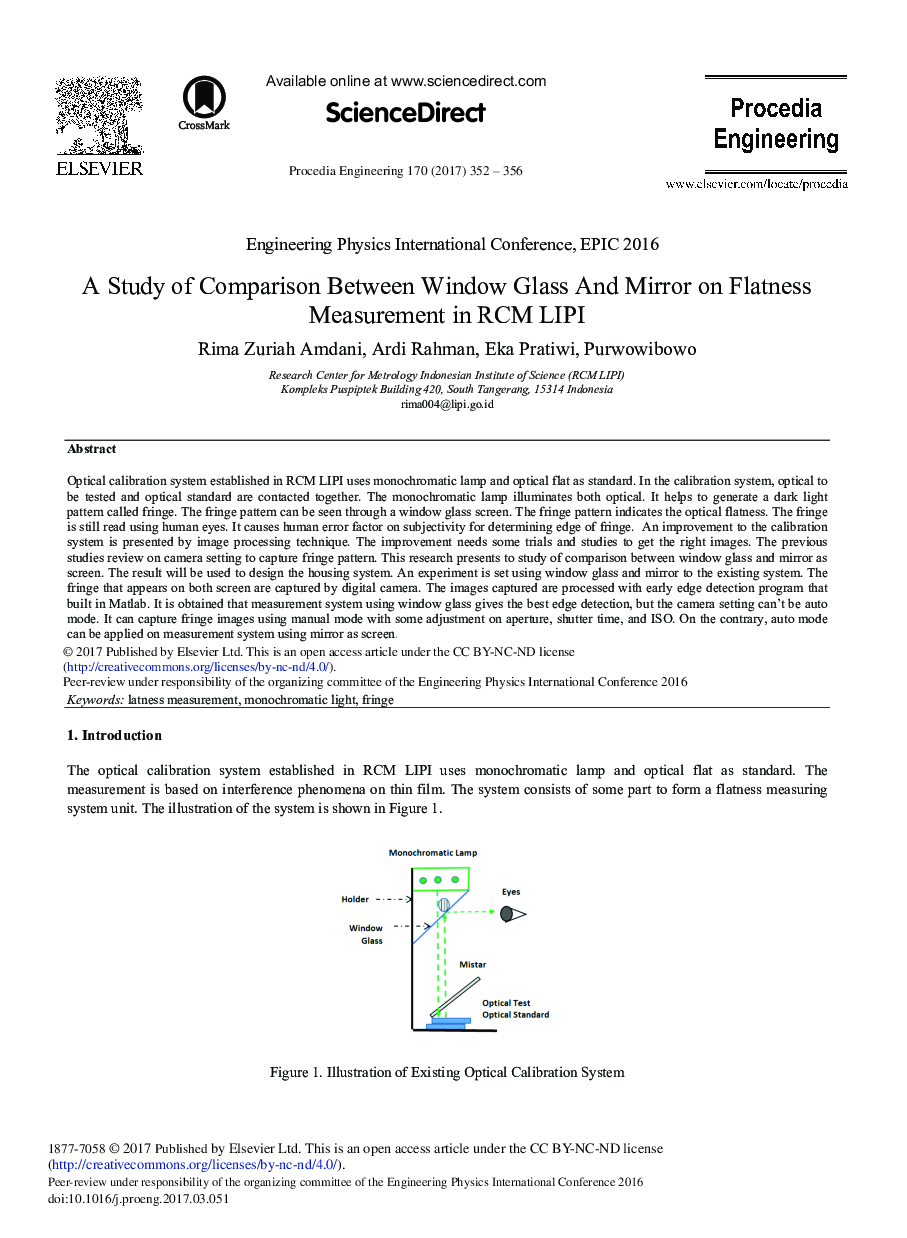

Optical calibration system established in RCM LIPI uses monochromatic lamp and optical flat as standard. In the calibration system, optical to be tested and optical standard are contacted together. The monochromatic lamp illuminates both optical. It helps to generate a dark light pattern called fringe. The fringe pattern can be seen through a window glass screen. The fringe pattern indicates the optical flatness. The fringe is still read using human eyes. It causes human error factor on subjectivity for determining edge of fringe. An improvement to the calibration system is presented by image processing technique. The improvement needs some trials and studies to get the right images. The previous studies review on camera setting to capture fringe pattern. This research presents to study of comparison between window glass and mirror as screen. The result will be used to design the housing system. An experiment is set using window glass and mirror to the existing system. The fringe that appears on both screen are captured by digital camera. The images captured are processed with early edge detection program that built in Matlab. It is obtained that measurement system using window glass gives the best edge detection, but the camera setting can't be auto mode. It can capture fringe images using manual mode with some adjustment on aperture, shutter time, and ISO. On the contrary, auto mode can be applied on measurement system using mirror as screen.

Keywords

Related Topics

Physical Sciences and Engineering

Engineering

Engineering (General)

Authors

Rima Zuriah Amdani, Ardi Rahman, Eka Pratiwi, Purwowibowo Purwowibowo,