| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 5466950 | CIRP Annals - Manufacturing Technology | 2017 | 4 Pages |

Abstract

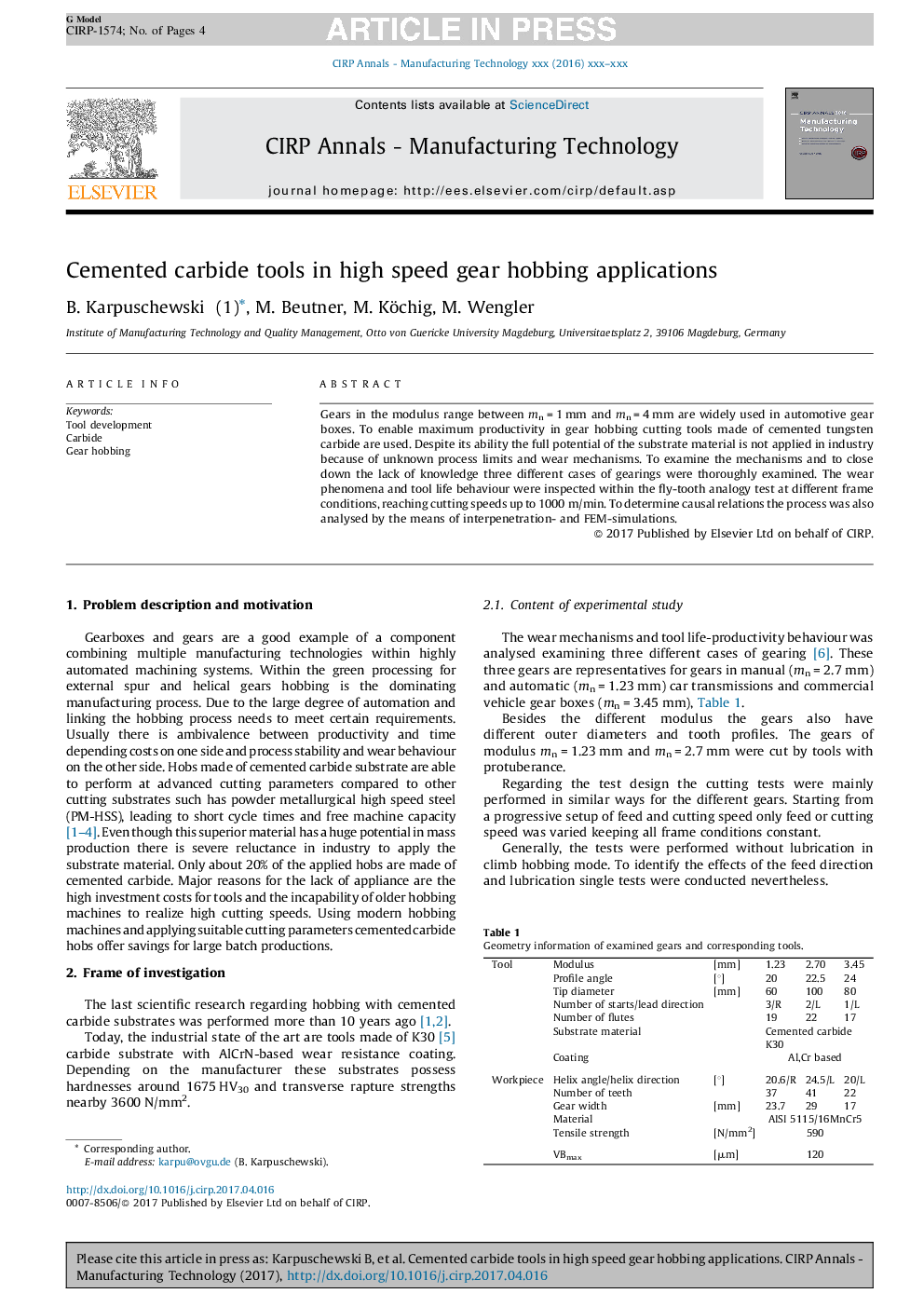

Gears in the modulus range between mn = 1 mm and mn = 4 mm are widely used in automotive gear boxes. To enable maximum productivity in gear hobbing cutting tools made of cemented tungsten carbide are used. Despite its ability the full potential of the substrate material is not applied in industry because of unknown process limits and wear mechanisms. To examine the mechanisms and to close down the lack of knowledge three different cases of gearings were thoroughly examined. The wear phenomena and tool life behaviour were inspected within the fly-tooth analogy test at different frame conditions, reaching cutting speeds up to 1000 m/min. To determine causal relations the process was also analysed by the means of interpenetration- and FEM-simulations.

Keywords

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

B. Karpuschewski, M. Beutner, M. Köchig, M. Wengler,