| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 5466988 | CIRP Annals - Manufacturing Technology | 2017 | 4 Pages |

Abstract

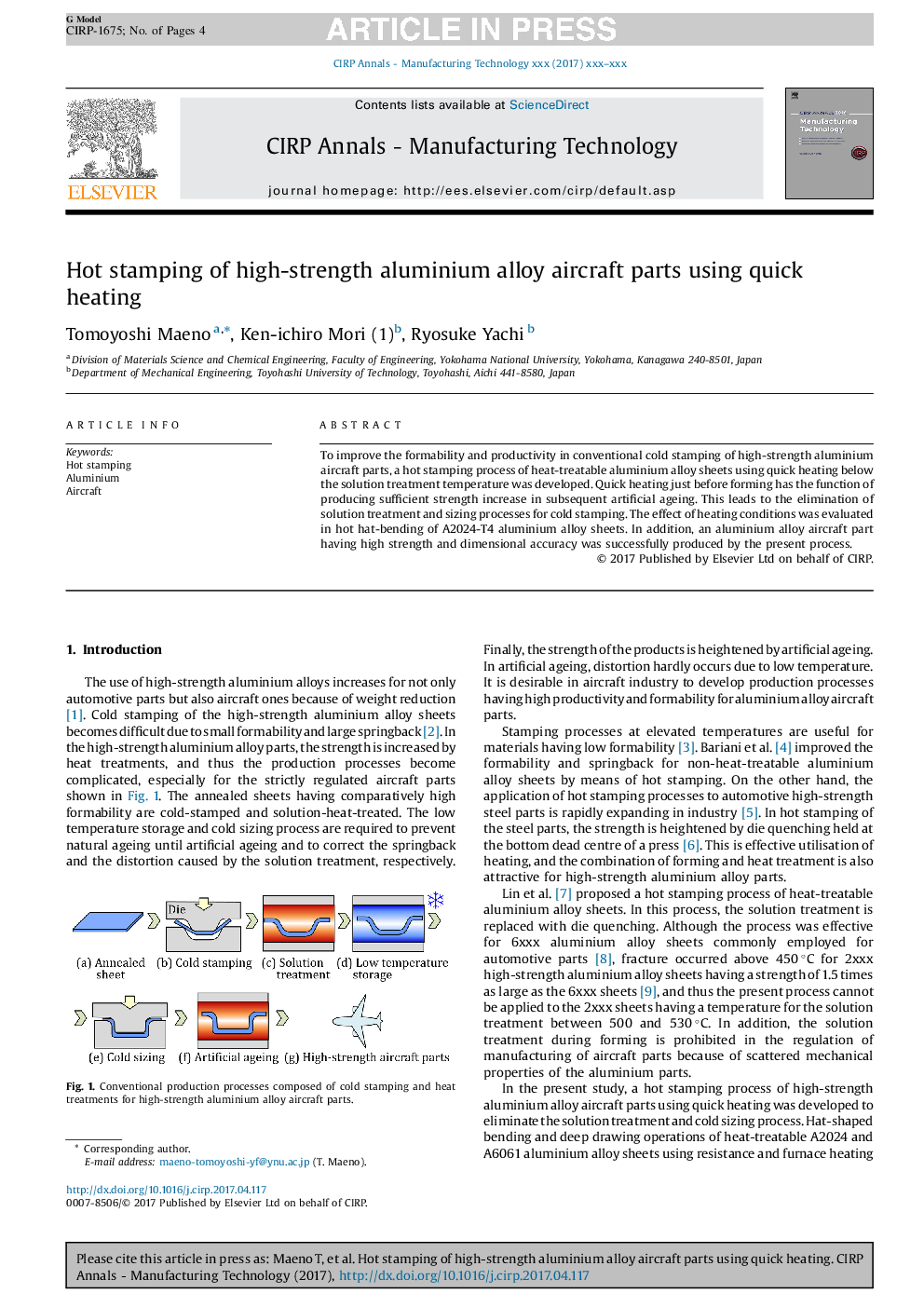

To improve the formability and productivity in conventional cold stamping of high-strength aluminium aircraft parts, a hot stamping process of heat-treatable aluminium alloy sheets using quick heating below the solution treatment temperature was developed. Quick heating just before forming has the function of producing sufficient strength increase in subsequent artificial ageing. This leads to the elimination of solution treatment and sizing processes for cold stamping. The effect of heating conditions was evaluated in hot hat-bending of A2024-T4 aluminium alloy sheets. In addition, an aluminium alloy aircraft part having high strength and dimensional accuracy was successfully produced by the present process.

Keywords

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

Tomoyoshi Maeno, Ken-ichiro Mori, Ryosuke Yachi,