| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 5466992 | CIRP Annals - Manufacturing Technology | 2017 | 4 Pages |

Abstract

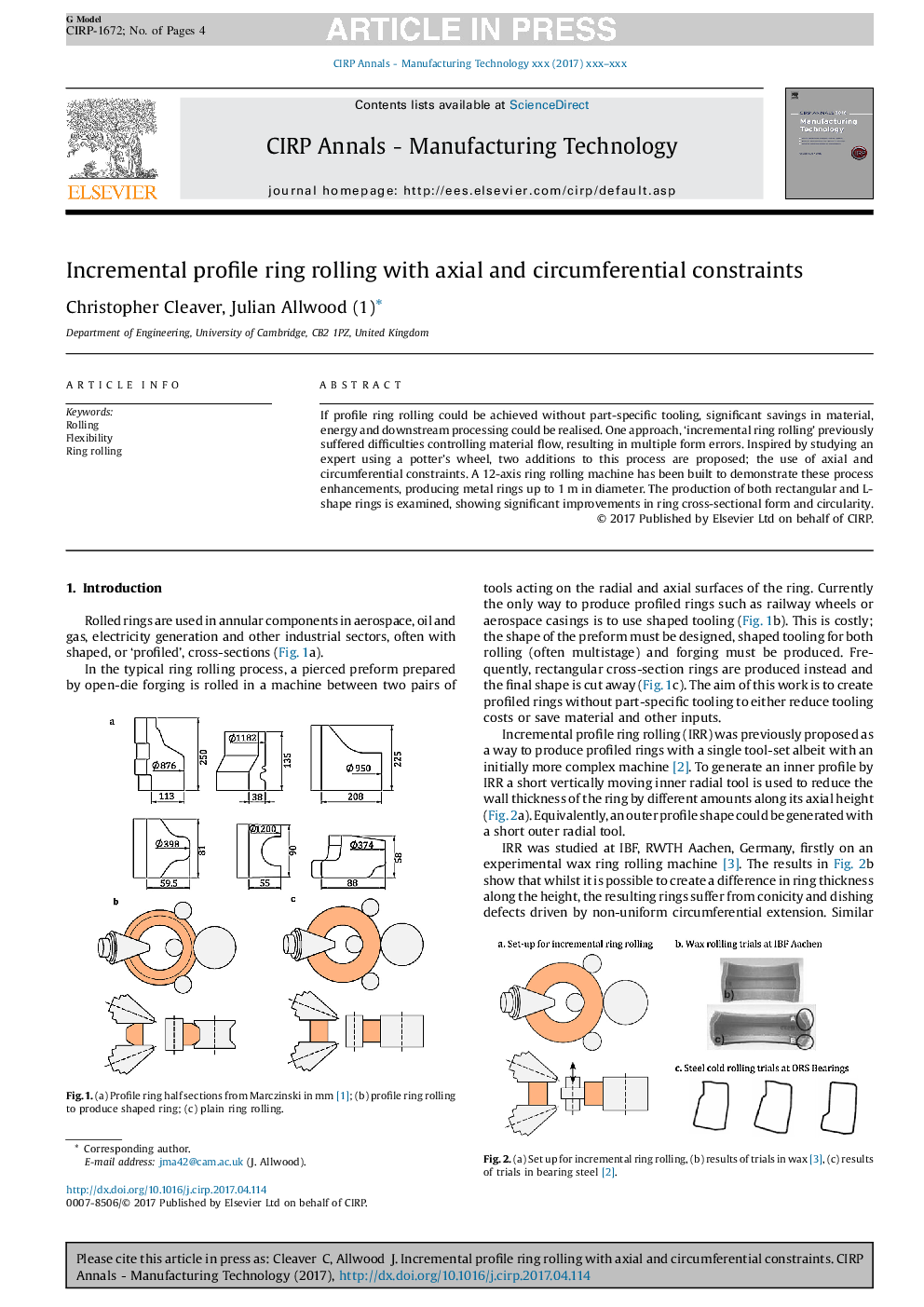

If profile ring rolling could be achieved without part-specific tooling, significant savings in material, energy and downstream processing could be realised. One approach, 'incremental ring rolling' previously suffered difficulties controlling material flow, resulting in multiple form errors. Inspired by studying an expert using a potter's wheel, two additions to this process are proposed; the use of axial and circumferential constraints. A 12-axis ring rolling machine has been built to demonstrate these process enhancements, producing metal rings up to 1Â m in diameter. The production of both rectangular and L-shape rings is examined, showing significant improvements in ring cross-sectional form and circularity.

Keywords

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

Christopher Cleaver, Julian Allwood,