| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 5466996 | CIRP Annals - Manufacturing Technology | 2017 | 4 Pages |

Abstract

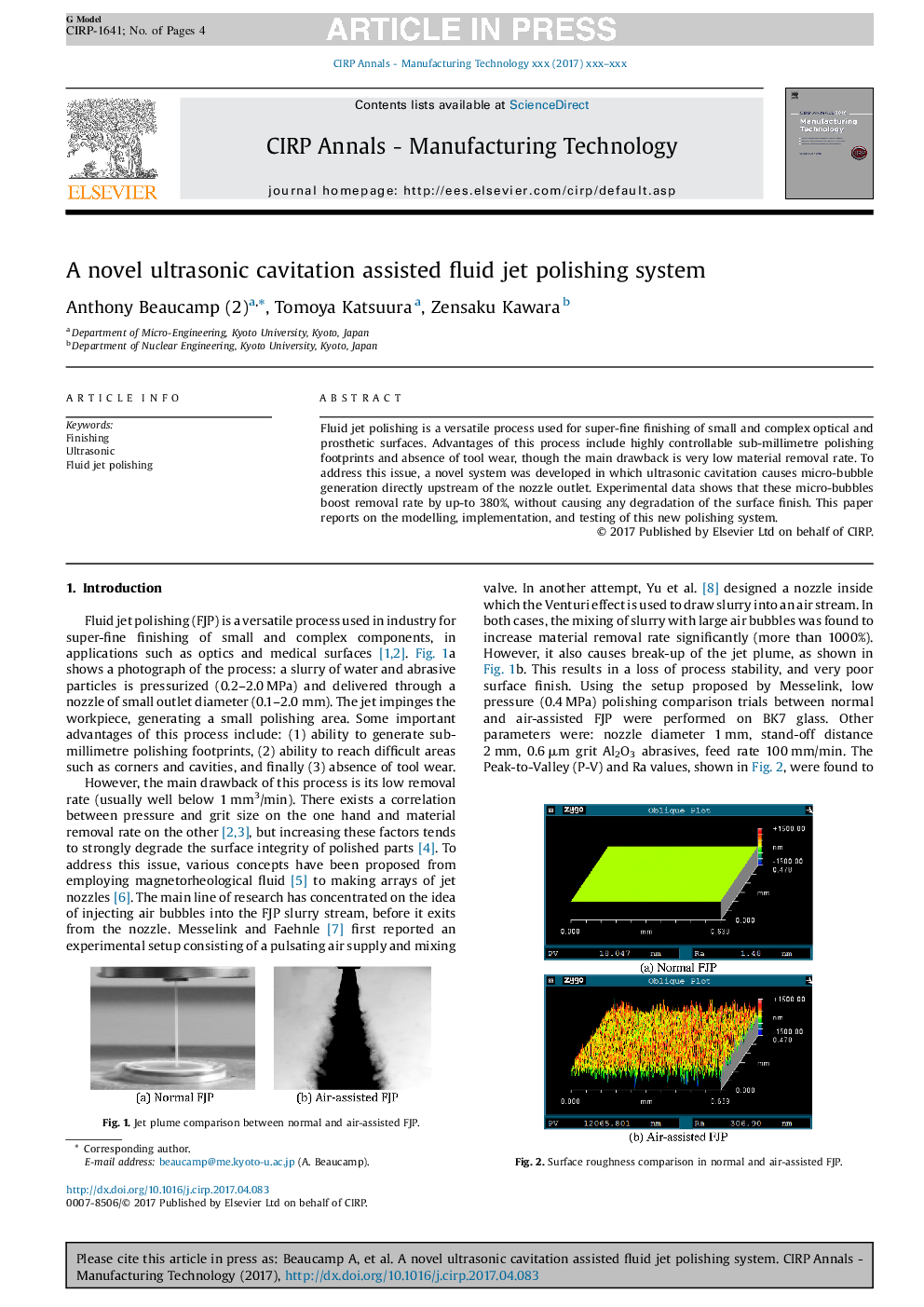

Fluid jet polishing is a versatile process used for super-fine finishing of small and complex optical and prosthetic surfaces. Advantages of this process include highly controllable sub-millimetre polishing footprints and absence of tool wear, though the main drawback is very low material removal rate. To address this issue, a novel system was developed in which ultrasonic cavitation causes micro-bubble generation directly upstream of the nozzle outlet. Experimental data shows that these micro-bubbles boost removal rate by up-to 380%, without causing any degradation of the surface finish. This paper reports on the modelling, implementation, and testing of this new polishing system.

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

Anthony Beaucamp, Tomoya Katsuura, Zensaku Kawara,