| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 5469785 | Procedia CIRP | 2016 | 6 Pages |

Abstract

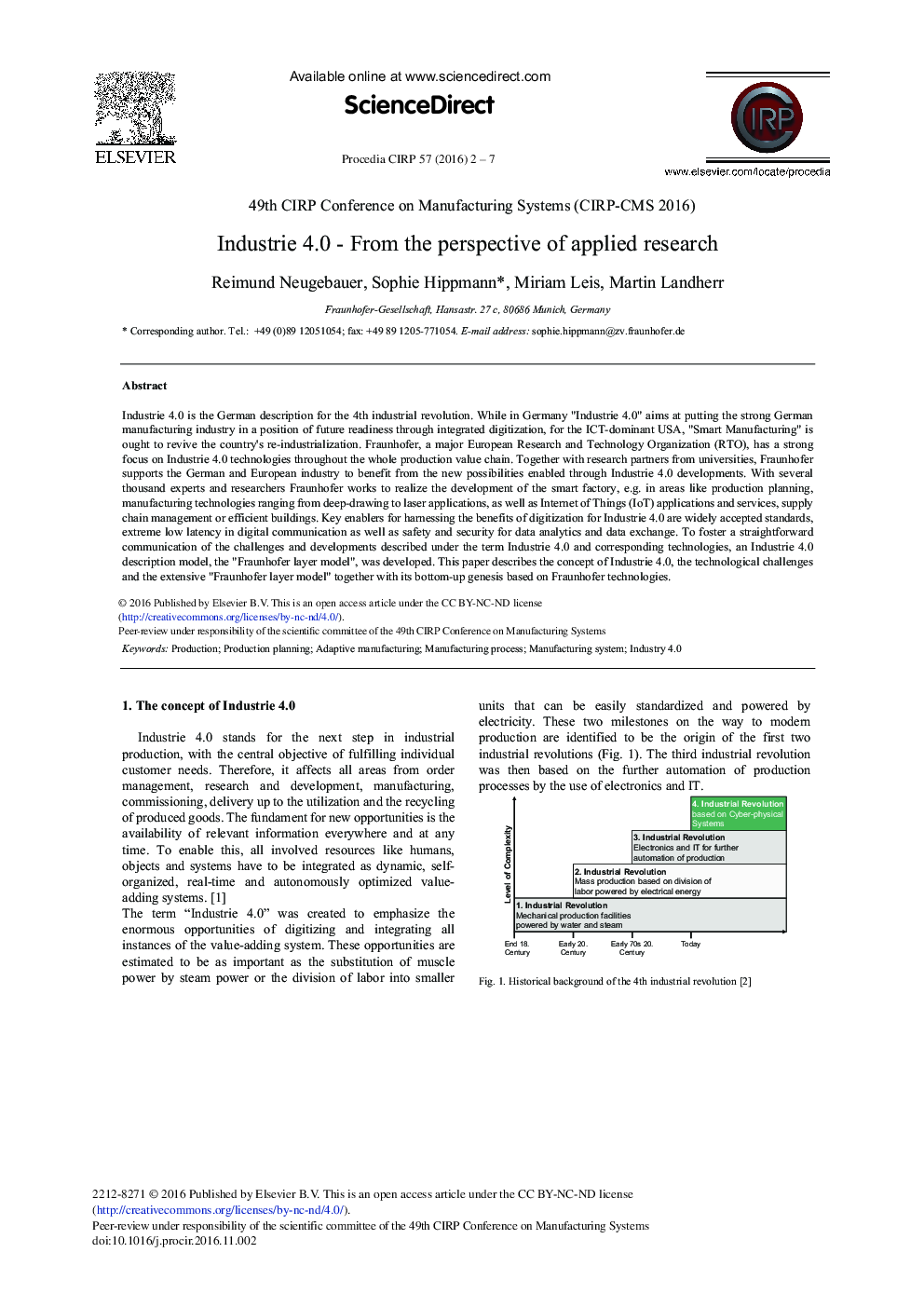

Industrie 4.0 is the German description for the 4th industrial revolution. While in Germany “Industrie 4.0” aims at putting the strong German manufacturing industry in a position of future readiness through integrated digitization, for the ICT-dominant USA, “Smart Manufacturing” is ought to revive the country's re-industrialization. Fraunhofer, a major European Research and Technology Organization (RTO), has a strong focus on Industrie 4.0 technologies throughout the whole production value chain. Together with research partners from universities, Fraunhofer supports the German and European industry to benefit from the new possibilities enabled through Industrie 4.0 developments. With several thousand experts and researchers Fraunhofer works to realize the development of the smart factory, e.g. in areas like production planning, manufacturing technologies ranging from deep-drawing to laser applications, as well as Internet of Things (IoT) applications and services, supply chain management or efficient buildings. Key enablers for harnessing the benefits of digitization for Industrie 4.0 are widely accepted standards, extreme low latency in digital communication as well as safety and security for data analytics and data exchange. To foster a straightforward communication of the challenges and developments described under the term Industrie 4.0 and corresponding technologies, an Industrie 4.0 description model, the “Fraunhofer layer model”, was developed. This paper describes the concept of Industrie 4.0, the technological challenges and the extensive “Fraunhofer layer model” together with its bottom-up genesis based on Fraunhofer technologies.

Keywords

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

Reimund Neugebauer, Sophie Hippmann, Miriam Leis, Martin Landherr,