| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 5470147 | Procedia CIRP | 2017 | 6 Pages |

Abstract

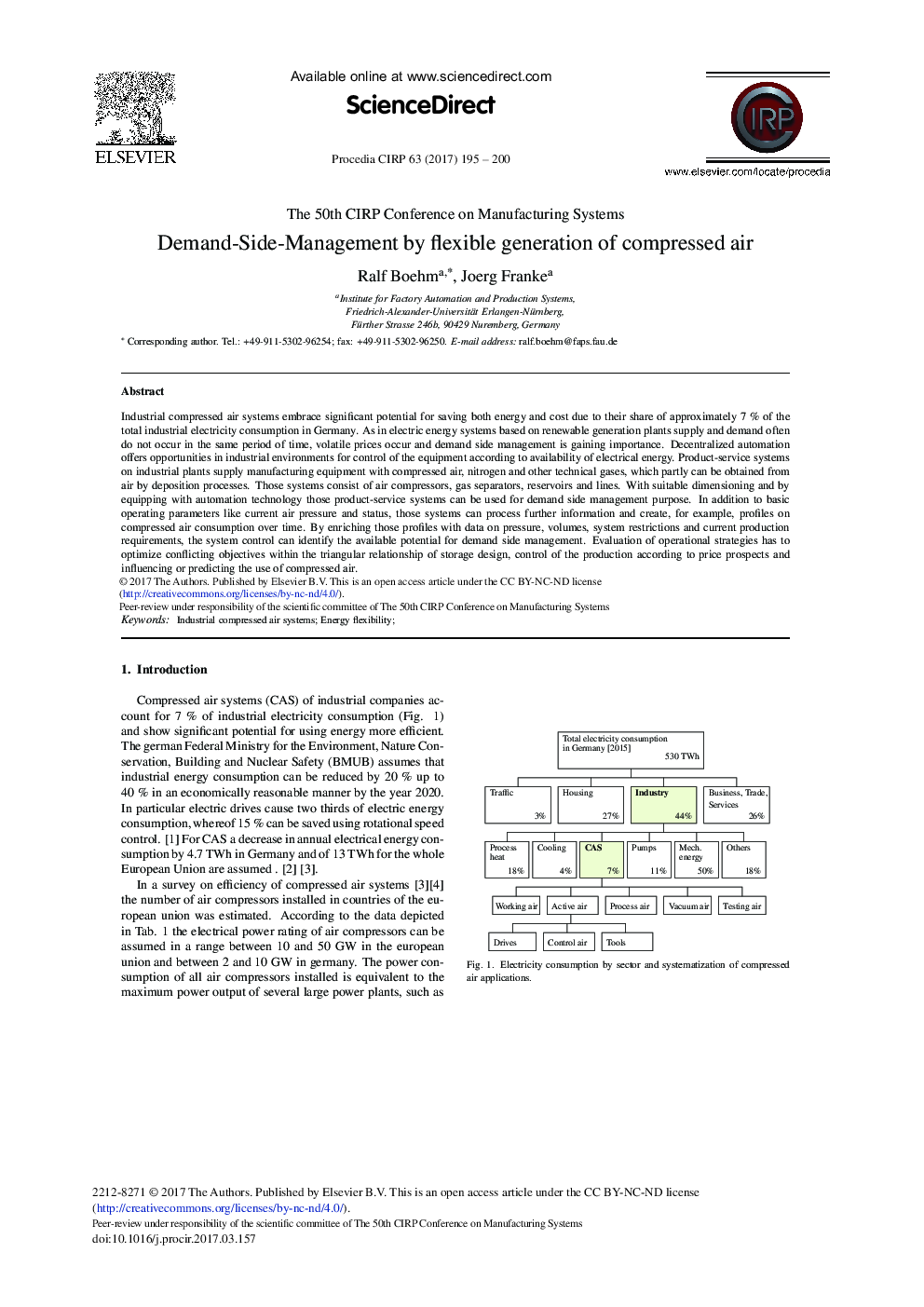

Industrial compressed air systems embrace significant potential for saving both energy and cost due to their share of approximately 7% of the total industrial electricity consumption in Germany. As in electric energy systems based on renewable generation plants supply and demand often do not occur in the same period of time, volatile prices occur and demand side management is gaining importance. Decentralized automation offers opportunities in industrial environments for control of the equipment according to availability of electrical energy. Product-service systems on industrial plants supply manufacturing equipment with compressed air, nitrogen and other technical gases, which partly can be obtained from air by deposition processes. Those systems consist of air compressors, gas separators, reservoirs and lines. With suitable dimensioning and by equipping with automation technology those product-service systems can be used for demand side management purpose. In addition to basic operating parameters like current air pressure and status, those systems can process further information and create, for example, profiles on compressed air consumption over time. By enriching those profiles with data on pressure, volumes, system restrictions and current production requirements, the system control can identify the available potential for demand side management. Evaluation of operational strategies has to optimize conflicting objectives within the triangular relationship of storage design, control of the production according to price prospects and influencing or predicting the use of compressed air.

Keywords

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

Ralf Boehm, Joerg Franke,