| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 5470287 | Procedia CIRP | 2017 | 6 Pages |

Abstract

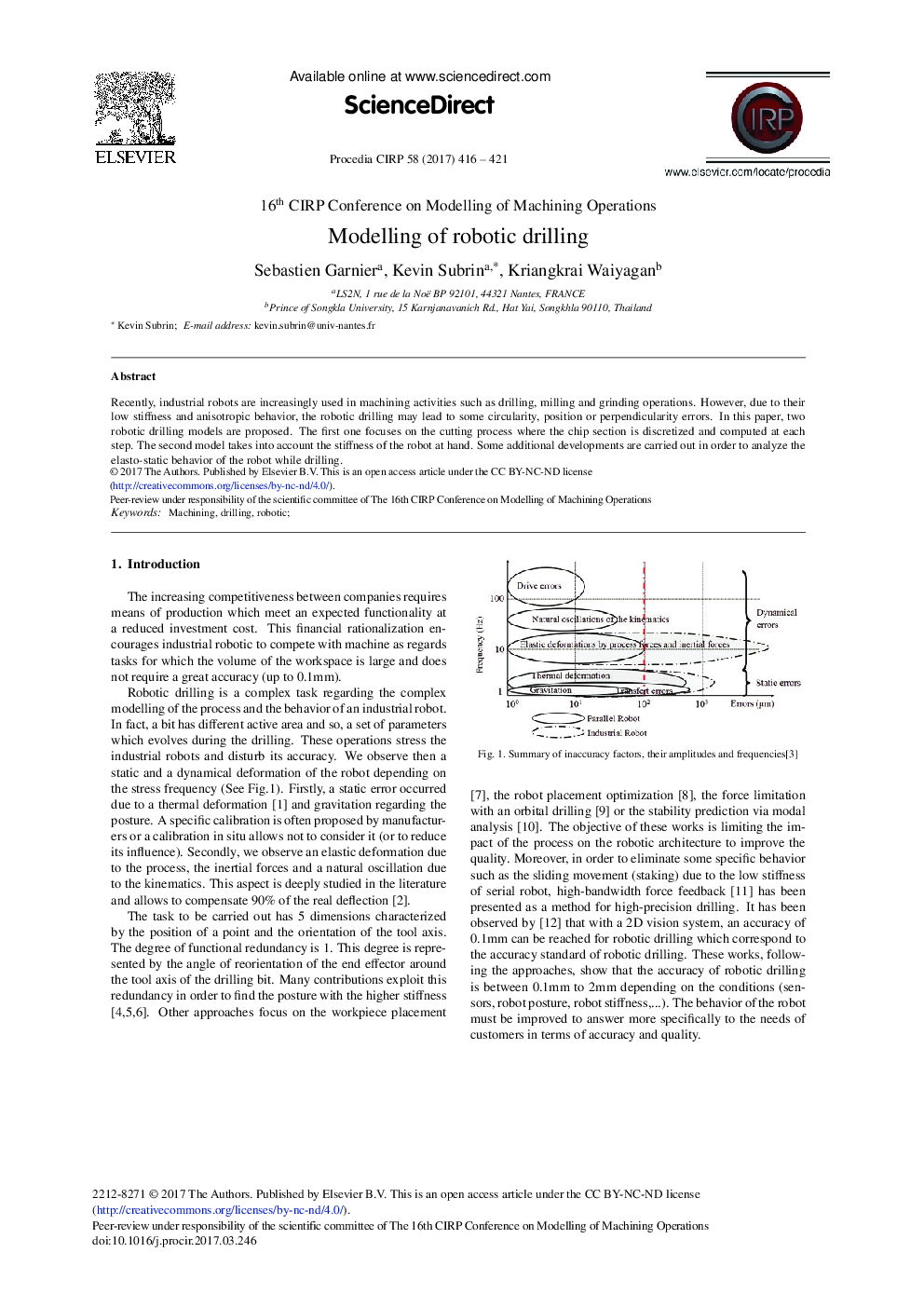

Recently, industrial robots are increasingly used in machining activities such as drilling, milling and grinding operations. However, due to their low stiffness and anisotropic behavior, the robotic drilling may lead to some circularity, position or perpendicularity errors. In this paper, two robotic drilling models are proposed. The first one focuses on the cutting process where the chip section is discretized and computed at each step. The second model takes into account the stiffness of the robot at hand. Some additional developments are carried out in order to analyze the elasto-static behavior of the robot while drilling.

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

Sebastien Garnier, Kevin Subrin, Kriangkrai Waiyagan,