| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 54958 | Catalysis Today | 2013 | 11 Pages |

•Rh–ReOx/silica catalyses 1,2,6-hexanetriol formation via hydrogenolysis.•Optimal yield was achieved at 85% selectivity at 31% conversion (120 °C, 80 bar, 4 h).•Harsher conditions catalyses 1,2,6-hexanetriol into diols and mono-alcohols.•Redox Re0/Reδ+ surface ratio correlates with the product yield.•Bifunctional mechanism is supported by gas phase and cluster DFT calculations.

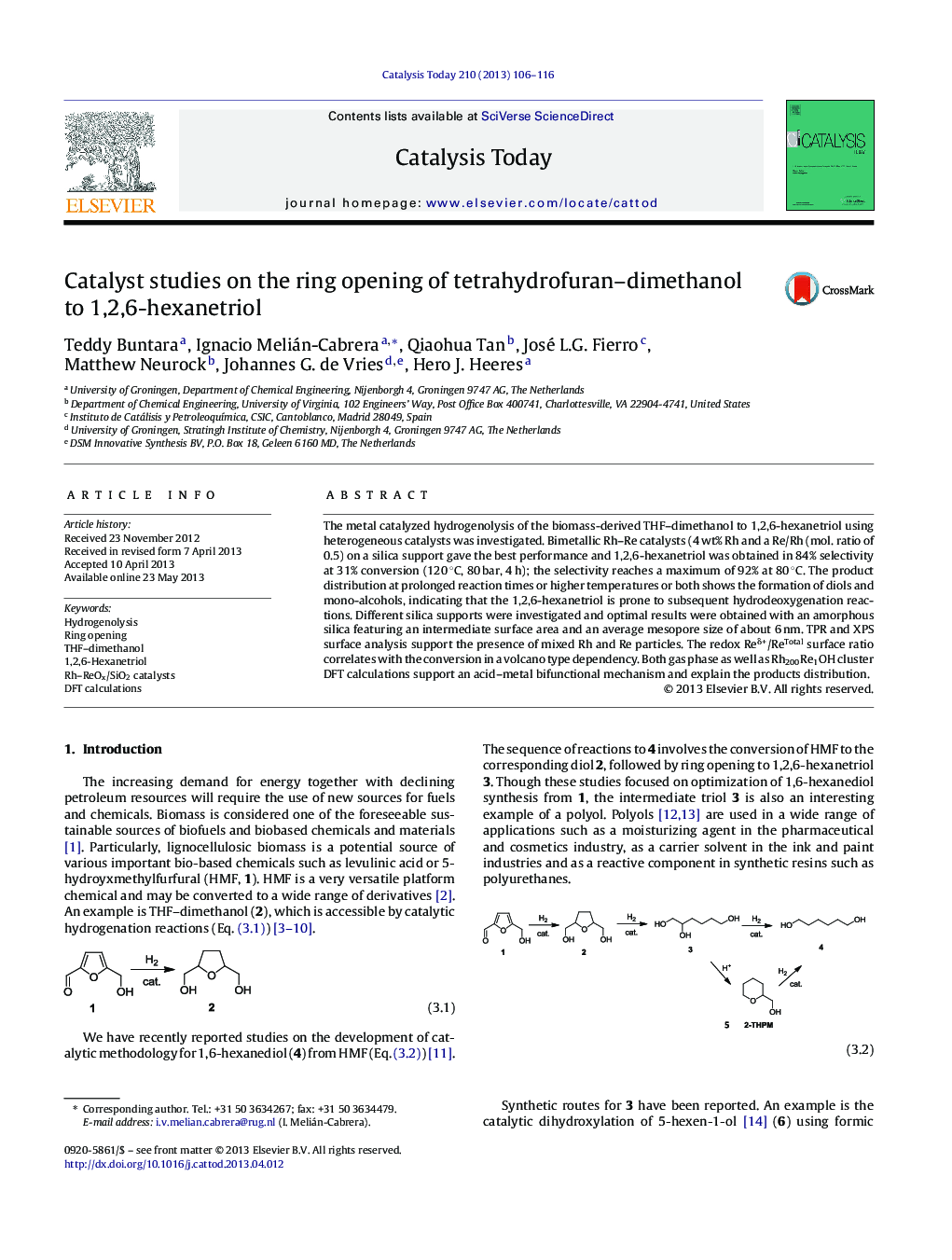

The metal catalyzed hydrogenolysis of the biomass-derived THF–dimethanol to 1,2,6-hexanetriol using heterogeneous catalysts was investigated. Bimetallic Rh–Re catalysts (4 wt% Rh and a Re/Rh (mol. ratio of 0.5) on a silica support gave the best performance and 1,2,6-hexanetriol was obtained in 84% selectivity at 31% conversion (120 °C, 80 bar, 4 h); the selectivity reaches a maximum of 92% at 80 °C. The product distribution at prolonged reaction times or higher temperatures or both shows the formation of diols and mono-alcohols, indicating that the 1,2,6-hexanetriol is prone to subsequent hydrodeoxygenation reactions. Different silica supports were investigated and optimal results were obtained with an amorphous silica featuring an intermediate surface area and an average mesopore size of about 6 nm. TPR and XPS surface analysis support the presence of mixed Rh and Re particles. The redox Reδ+/ReTotal surface ratio correlates with the conversion in a volcano type dependency. Both gas phase as well as Rh200Re1OH cluster DFT calculations support an acid–metal bifunctional mechanism and explain the products distribution.

Graphical abstractFigure optionsDownload full-size imageDownload high-quality image (57 K)Download as PowerPoint slide