| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 619946 | Wear | 2006 | 8 Pages |

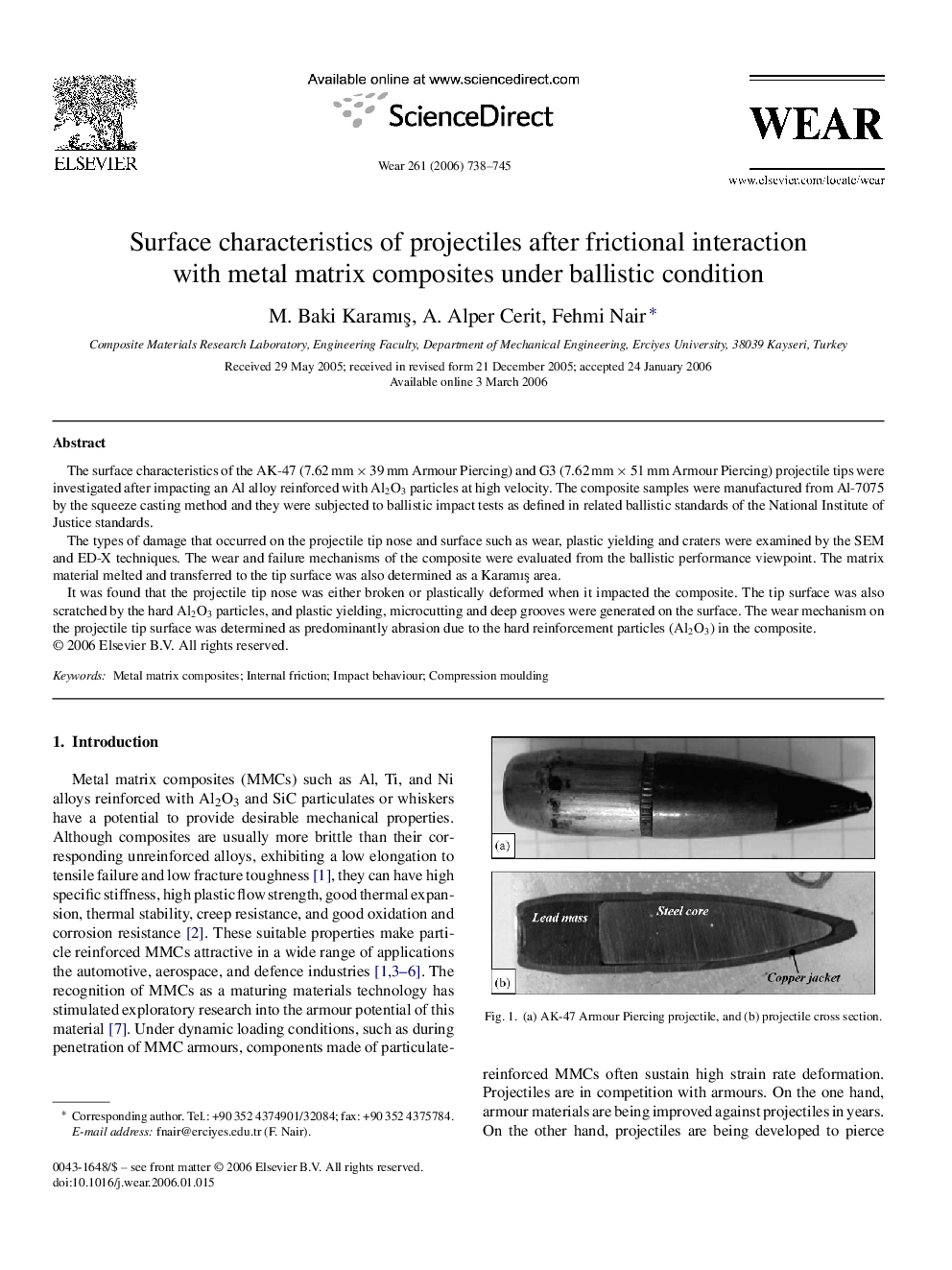

The surface characteristics of the AK-47 (7.62 mm × 39 mm Armour Piercing) and G3 (7.62 mm × 51 mm Armour Piercing) projectile tips were investigated after impacting an Al alloy reinforced with Al2O3 particles at high velocity. The composite samples were manufactured from Al-7075 by the squeeze casting method and they were subjected to ballistic impact tests as defined in related ballistic standards of the National Institute of Justice standards.The types of damage that occurred on the projectile tip nose and surface such as wear, plastic yielding and craters were examined by the SEM and ED-X techniques. The wear and failure mechanisms of the composite were evaluated from the ballistic performance viewpoint. The matrix material melted and transferred to the tip surface was also determined as a Karamış area.It was found that the projectile tip nose was either broken or plastically deformed when it impacted the composite. The tip surface was also scratched by the hard Al2O3 particles, and plastic yielding, microcutting and deep grooves were generated on the surface. The wear mechanism on the projectile tip surface was determined as predominantly abrasion due to the hard reinforcement particles (Al2O3) in the composite.