| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 622760 | Desalination | 2016 | 13 Pages |

•Direct contact membrane distillation (DCMD) was trialled for three months.•Trial pilot plant supplied with waste heat < 40 °C from power station•Water recovery 92.8% reached treating ion exchange regeneration effluent•Trial fluxes between 2 to 5 L/(m2·h), sensitive to heating or cooling temperatures•Membrane fouling observed, while total dissolved solid rejections always > 99.8%.

Direct contact membrane distillation (DCMD) supplied with waste heat was demonstrated for water recovery from saline demineralisation regeneration waste. The pilot plant was located at a gas fired power station which provided the < 40 °C waste heat and wastewater to the DCMD system with 0.67 m2 of membrane area. The trial was operated over three months without replacing the membranes or module and achieved 92.8% water recovery. Flux was approximately 3 L/(m2·h) and was dependant mostly on the waste heat temperature being supplied. Membrane fouling affected flux and thermal energy demand only at the very end of the trial. The system produced a high quality distillate product with average 99.9% dissolved solids rejection. Small amounts of ammonia and carbon dioxide however were found in the permeate. Membrane analysis post-trial revealed fouling was principally inorganic scale but organic matter on the membrane was also evident. Permeate side fouling was also observed, attributed to corrosion of the cooling heat exchanger. Based on the available energy for a continuously operating 500 MW (electric) rated power station, the treatment potential was estimated at up to 8000 kL/day, which is practical for supplying water to numerous industrial, residential or agricultural sites.

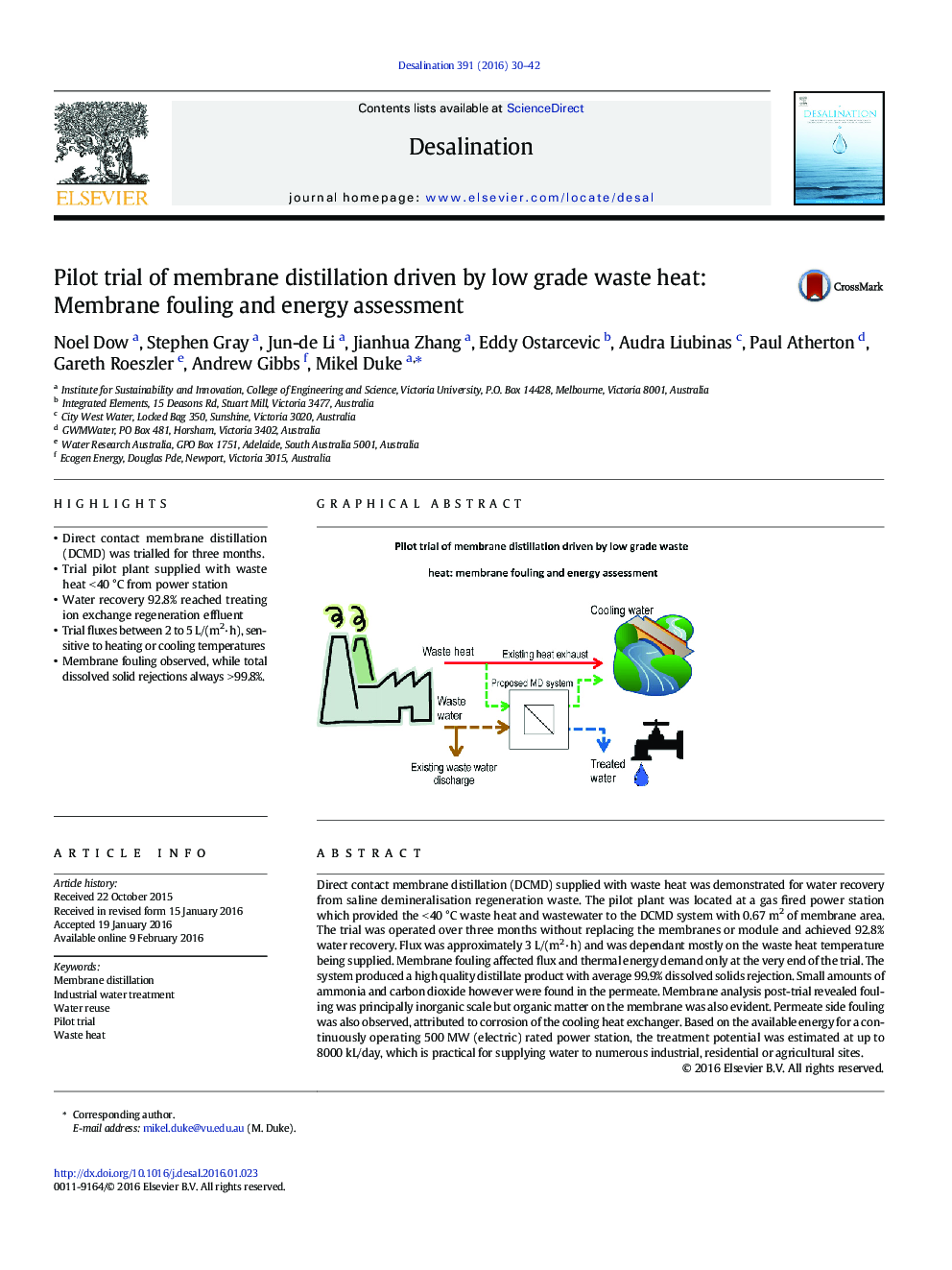

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide