| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 6467052 | Chemical Engineering Science | 2017 | 14 Pages |

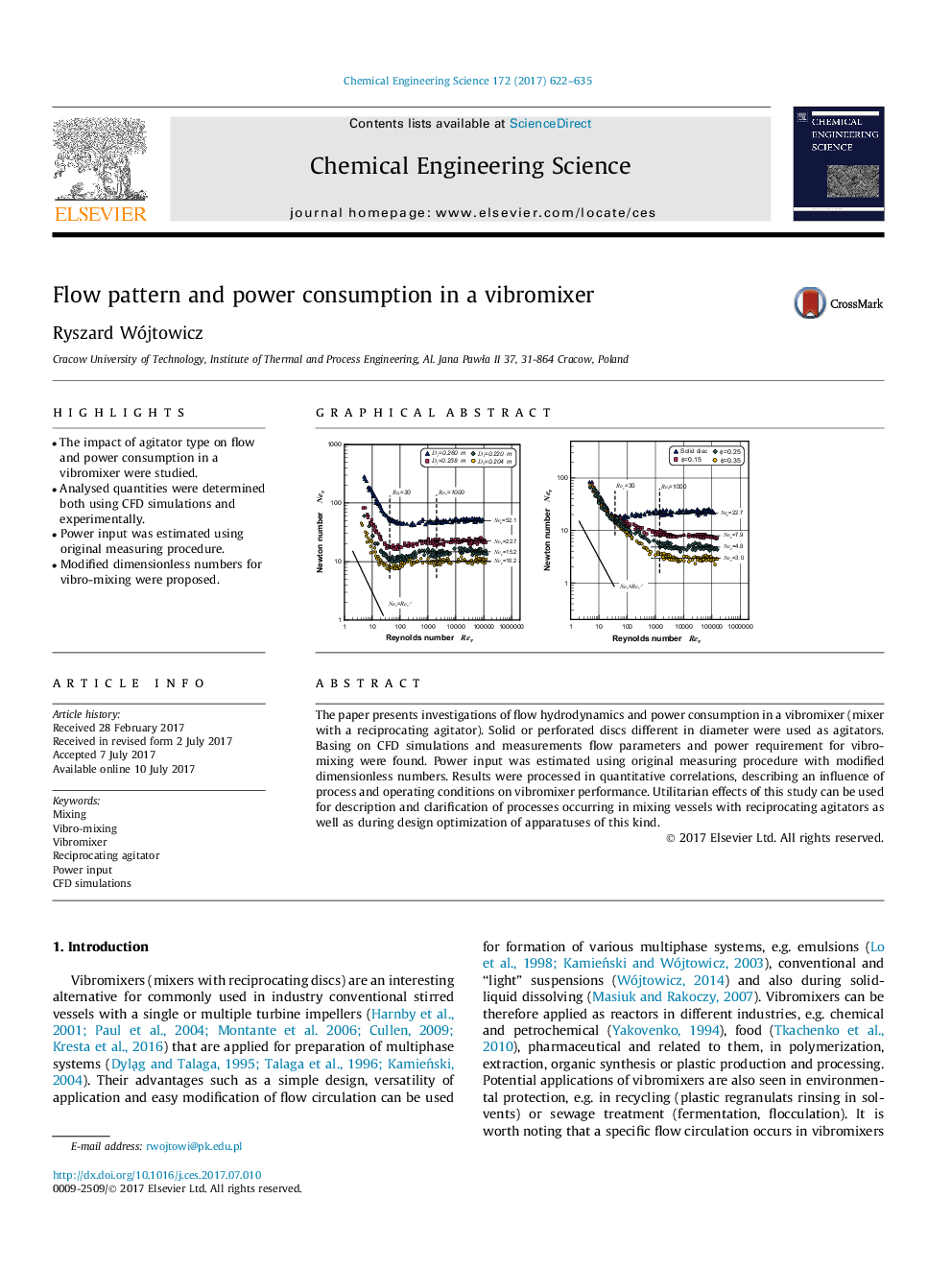

â¢The impact of agitator type on flow and power consumption in a vibromixer were studied.â¢Analysed quantities were determined both using CFD simulations and experimentally.â¢Power input was estimated using original measuring procedure.â¢Modified dimensionless numbers for vibro-mixing were proposed.

The paper presents investigations of flow hydrodynamics and power consumption in a vibromixer (mixer with a reciprocating agitator). Solid or perforated discs different in diameter were used as agitators. Basing on CFD simulations and measurements flow parameters and power requirement for vibro-mixing were found. Power input was estimated using original measuring procedure with modified dimensionless numbers. Results were processed in quantitative correlations, describing an influence of process and operating conditions on vibromixer performance. Utilitarian effects of this study can be used for description and clarification of processes occurring in mixing vessels with reciprocating agitators as well as during design optimization of apparatuses of this kind.

Graphical abstractDownload high-res image (336KB)Download full-size image