| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 6467463 | Chemical Engineering Science | 2017 | 7 Pages |

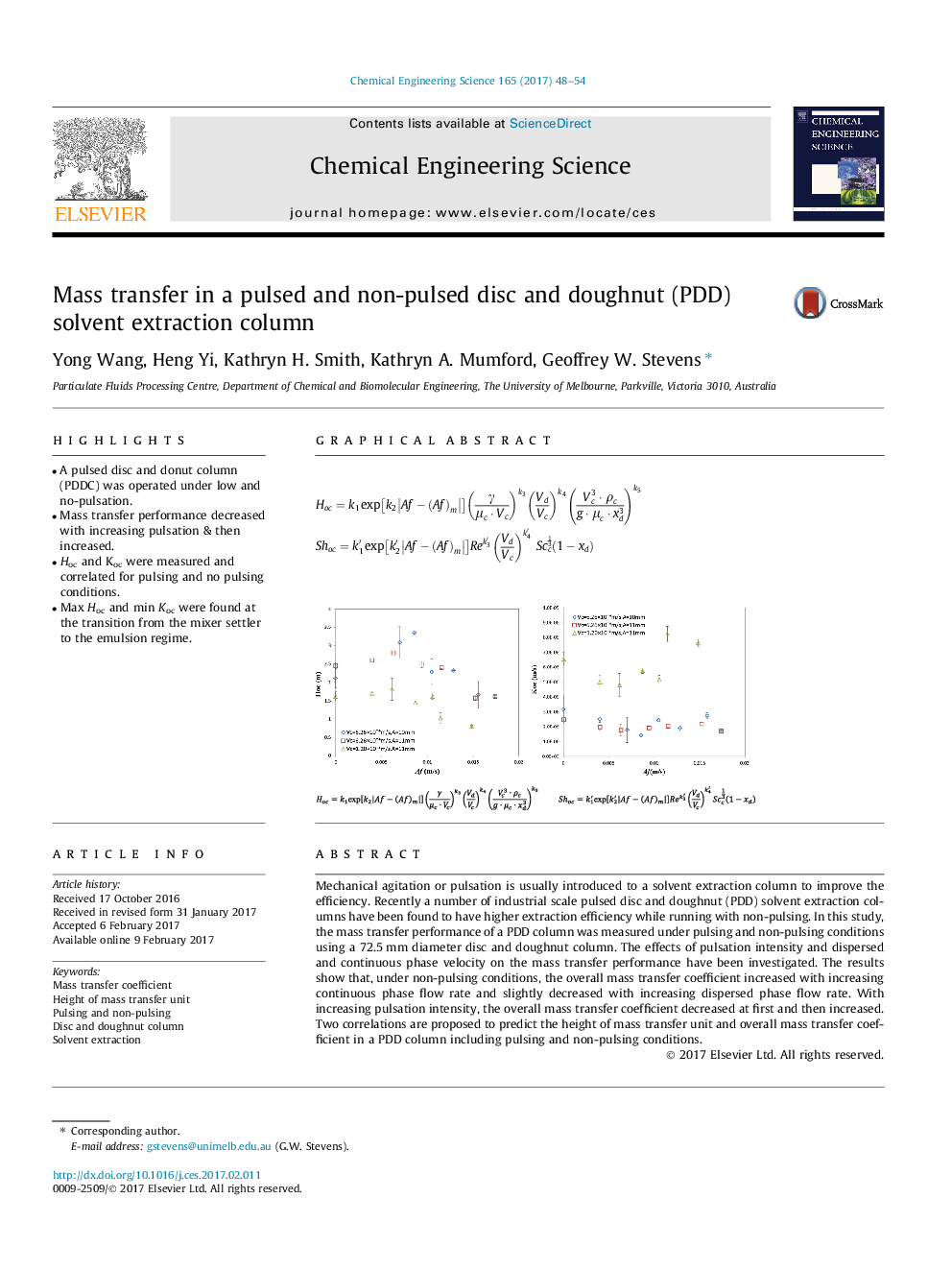

â¢A pulsed disc and donut column (PDDC) was operated under low and no-pulsation.â¢Mass transfer performance decreased with increasing pulsation & then increased.â¢Hoc and Koc were measured and correlated for pulsing and no pulsing conditions.â¢Max Hoc and min Koc were found at the transition from the mixer settler to the emulsion regime.

Mechanical agitation or pulsation is usually introduced to a solvent extraction column to improve the efficiency. Recently a number of industrial scale pulsed disc and doughnut (PDD) solvent extraction columns have been found to have higher extraction efficiency while running with non-pulsing. In this study, the mass transfer performance of a PDD column was measured under pulsing and non-pulsing conditions using a 72.5Â mm diameter disc and doughnut column. The effects of pulsation intensity and dispersed and continuous phase velocity on the mass transfer performance have been investigated. The results show that, under non-pulsing conditions, the overall mass transfer coefficient increased with increasing continuous phase flow rate and slightly decreased with increasing dispersed phase flow rate. With increasing pulsation intensity, the overall mass transfer coefficient decreased at first and then increased. Two correlations are proposed to predict the height of mass transfer unit and overall mass transfer coefficient in a PDD column including pulsing and non-pulsing conditions.

Graphical abstractHoc=k1expk2Af-(Af)mγμc·Vck3VdVck4Vc3·Ïcg·μc·xd3k5Shoc=k1â²expk2â²Af-(Af)mRek3â²VdVck4â²Scc13(1-xd)Download high-res image (137KB)Download full-size image