| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 6473783 | Fuel | 2017 | 8 Pages |

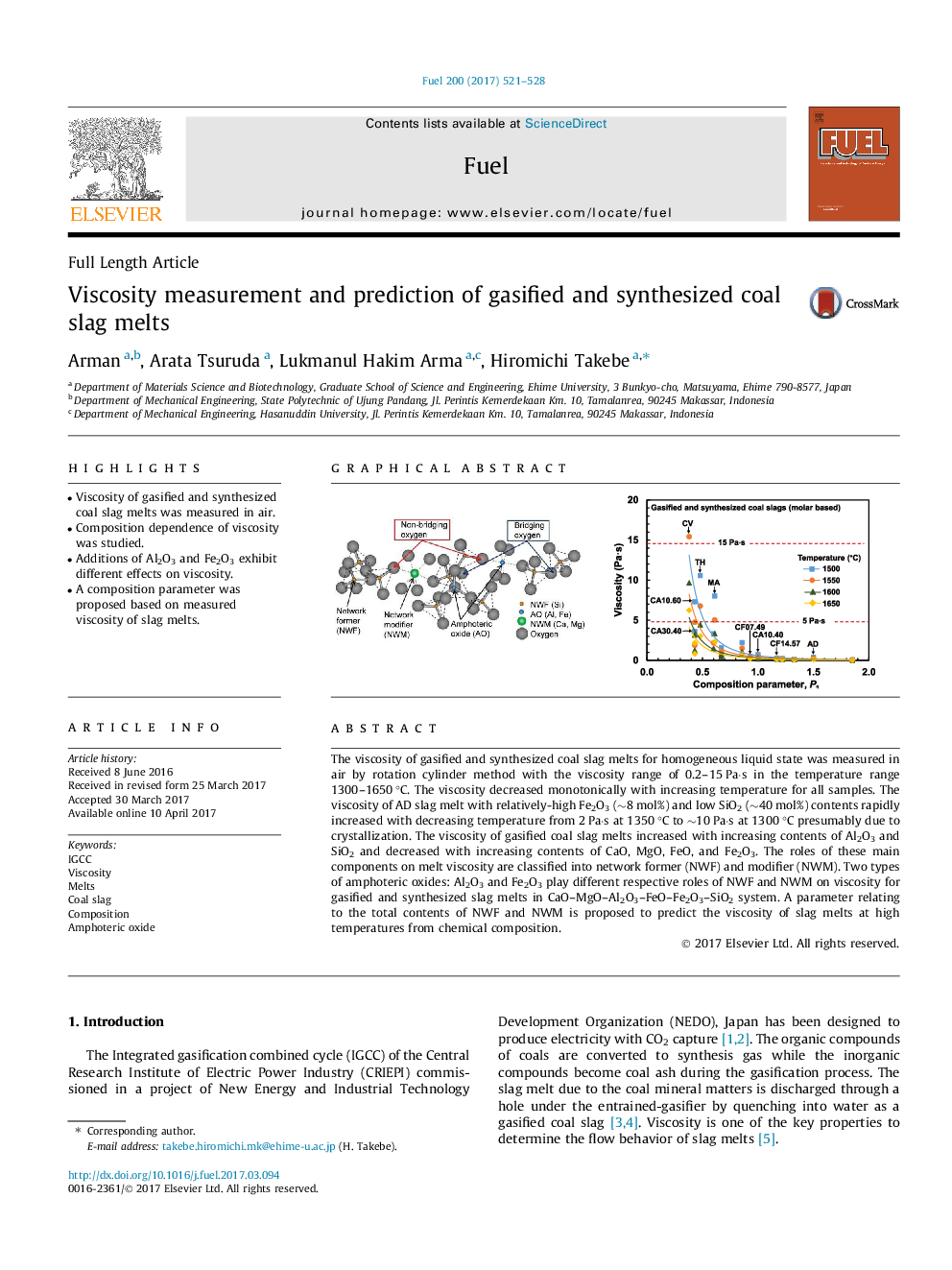

â¢Viscosity of gasified and synthesized coal slag melts was measured in air.â¢Composition dependence of viscosity was studied.â¢Additions of Al2O3 and Fe2O3 exhibit different effects on viscosity.â¢A composition parameter was proposed based on measured viscosity of slag melts.

The viscosity of gasified and synthesized coal slag melts for homogeneous liquid state was measured in air by rotation cylinder method with the viscosity range of 0.2-15 Pa·s in the temperature range 1300-1650 °C. The viscosity decreased monotonically with increasing temperature for all samples. The viscosity of AD slag melt with relatively-high Fe2O3 (â¼8 mol%) and low SiO2 (â¼40 mol%) contents rapidly increased with decreasing temperature from 2 Pa·s at 1350 °C to â¼10 Pa·s at 1300 °C presumably due to crystallization. The viscosity of gasified coal slag melts increased with increasing contents of Al2O3 and SiO2 and decreased with increasing contents of CaO, MgO, FeO, and Fe2O3. The roles of these main components on melt viscosity are classified into network former (NWF) and modifier (NWM). Two types of amphoteric oxides: Al2O3 and Fe2O3 play different respective roles of NWF and NWM on viscosity for gasified and synthesized slag melts in CaO-MgO-Al2O3-FeO-Fe2O3-SiO2 system. A parameter relating to the total contents of NWF and NWM is proposed to predict the viscosity of slag melts at high temperatures from chemical composition.

Graphical abstractDownload high-res image (203KB)Download full-size image