| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 6474409 | Fuel | 2017 | 11 Pages |

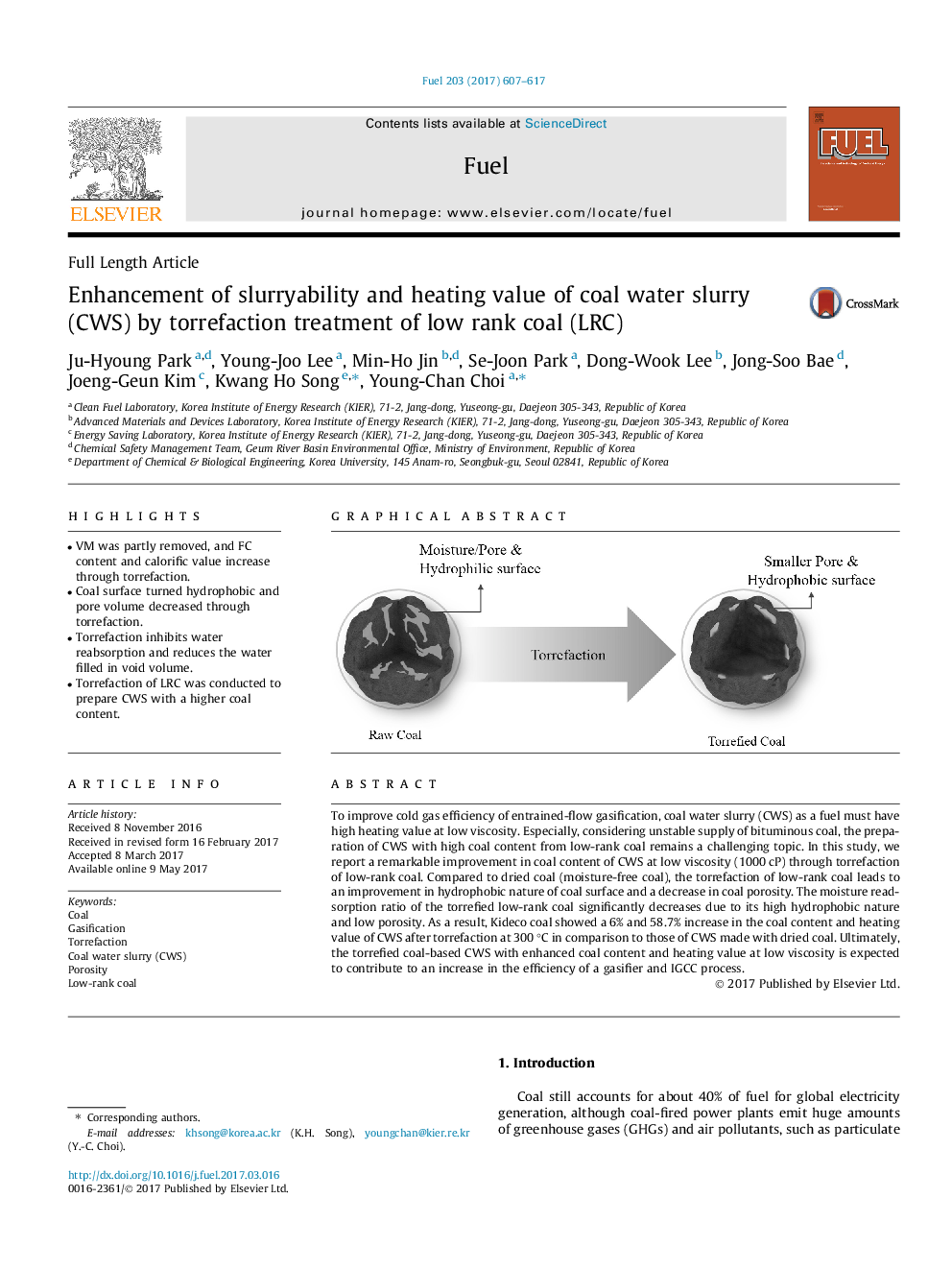

â¢VM was partly removed, and FC content and calorific value increase through torrefaction.â¢Coal surface turned hydrophobic and pore volume decreased through torrefaction.â¢Torrefaction inhibits water reabsorption and reduces the water filled in void volume.â¢Torrefaction of LRC was conducted to prepare CWS with a higher coal content.

To improve cold gas efficiency of entrained-flow gasification, coal water slurry (CWS) as a fuel must have high heating value at low viscosity. Especially, considering unstable supply of bituminous coal, the preparation of CWS with high coal content from low-rank coal remains a challenging topic. In this study, we report a remarkable improvement in coal content of CWS at low viscosity (1000 cP) through torrefaction of low-rank coal. Compared to dried coal (moisture-free coal), the torrefaction of low-rank coal leads to an improvement in hydrophobic nature of coal surface and a decrease in coal porosity. The moisture readsorption ratio of the torrefied low-rank coal significantly decreases due to its high hydrophobic nature and low porosity. As a result, Kideco coal showed a 6% and 58.7% increase in the coal content and heating value of CWS after torrefaction at 300 °C in comparison to those of CWS made with dried coal. Ultimately, the torrefied coal-based CWS with enhanced coal content and heating value at low viscosity is expected to contribute to an increase in the efficiency of a gasifier and IGCC process.

Graphical abstractDownload high-res image (68KB)Download full-size image