| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 6474504 | Fuel | 2017 | 10 Pages |

â¢Numerically and experimental investigations of different HP POX burner concepts.â¢Validation of the CFD setup using optical measurements of the flame structure.â¢Validation of the CFD setup using global outlet conditions.â¢2D and 3D numerical study of different burner concepts.â¢New burner concepts show a potential for improving the reactor performance.

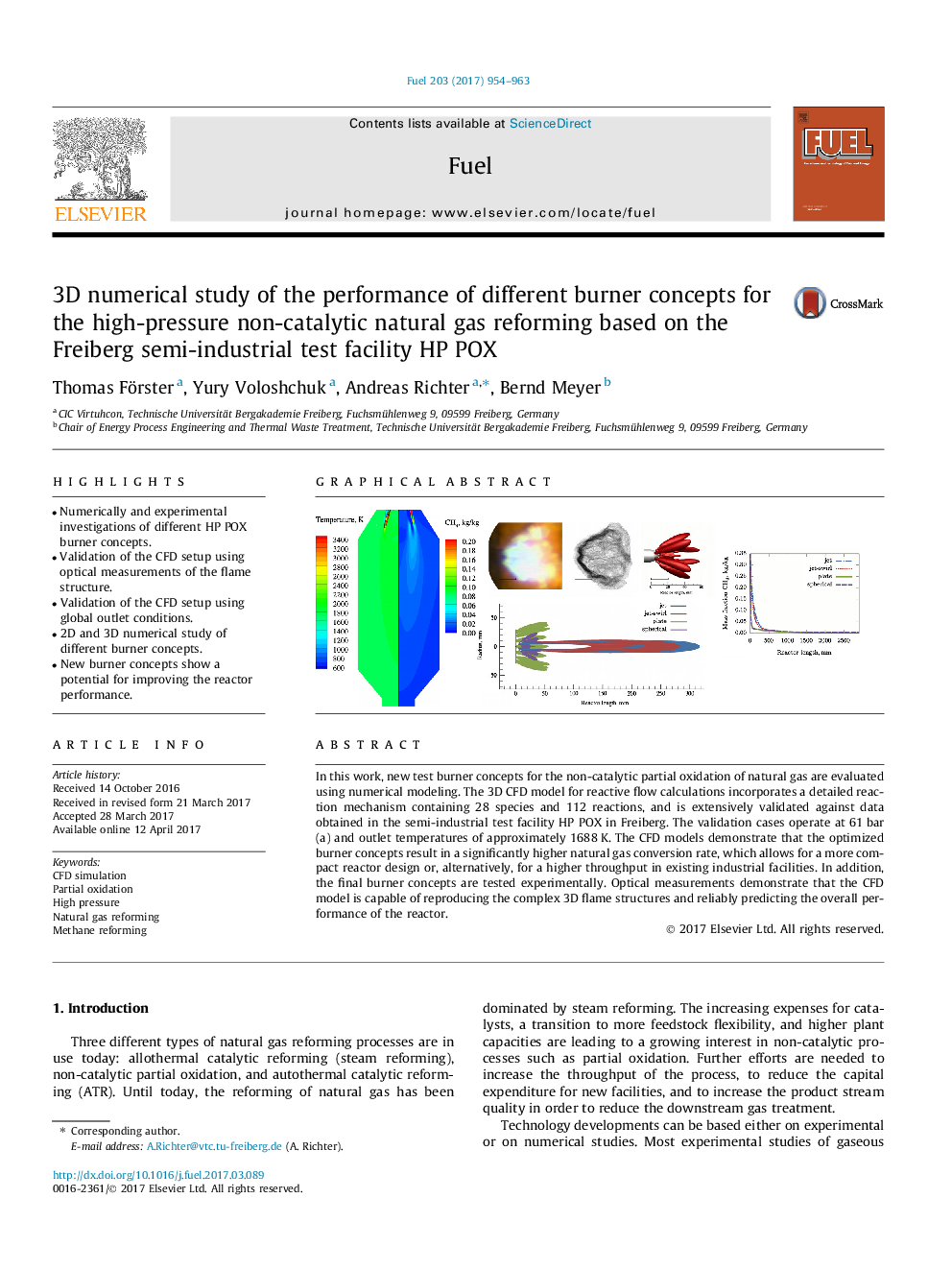

In this work, new test burner concepts for the non-catalytic partial oxidation of natural gas are evaluated using numerical modeling. The 3D CFD model for reactive flow calculations incorporates a detailed reaction mechanism containing 28 species and 112 reactions, and is extensively validated against data obtained in the semi-industrial test facility HP POX in Freiberg. The validation cases operate at 61Â bar(a) and outlet temperatures of approximately 1688Â K. The CFD models demonstrate that the optimized burner concepts result in a significantly higher natural gas conversion rate, which allows for a more compact reactor design or, alternatively, for a higher throughput in existing industrial facilities. In addition, the final burner concepts are tested experimentally. Optical measurements demonstrate that the CFD model is capable of reproducing the complex 3D flame structures and reliably predicting the overall performance of the reactor.

Graphical abstractDownload high-res image (195KB)Download full-size image