| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 6474797 | Fuel | 2017 | 8 Pages |

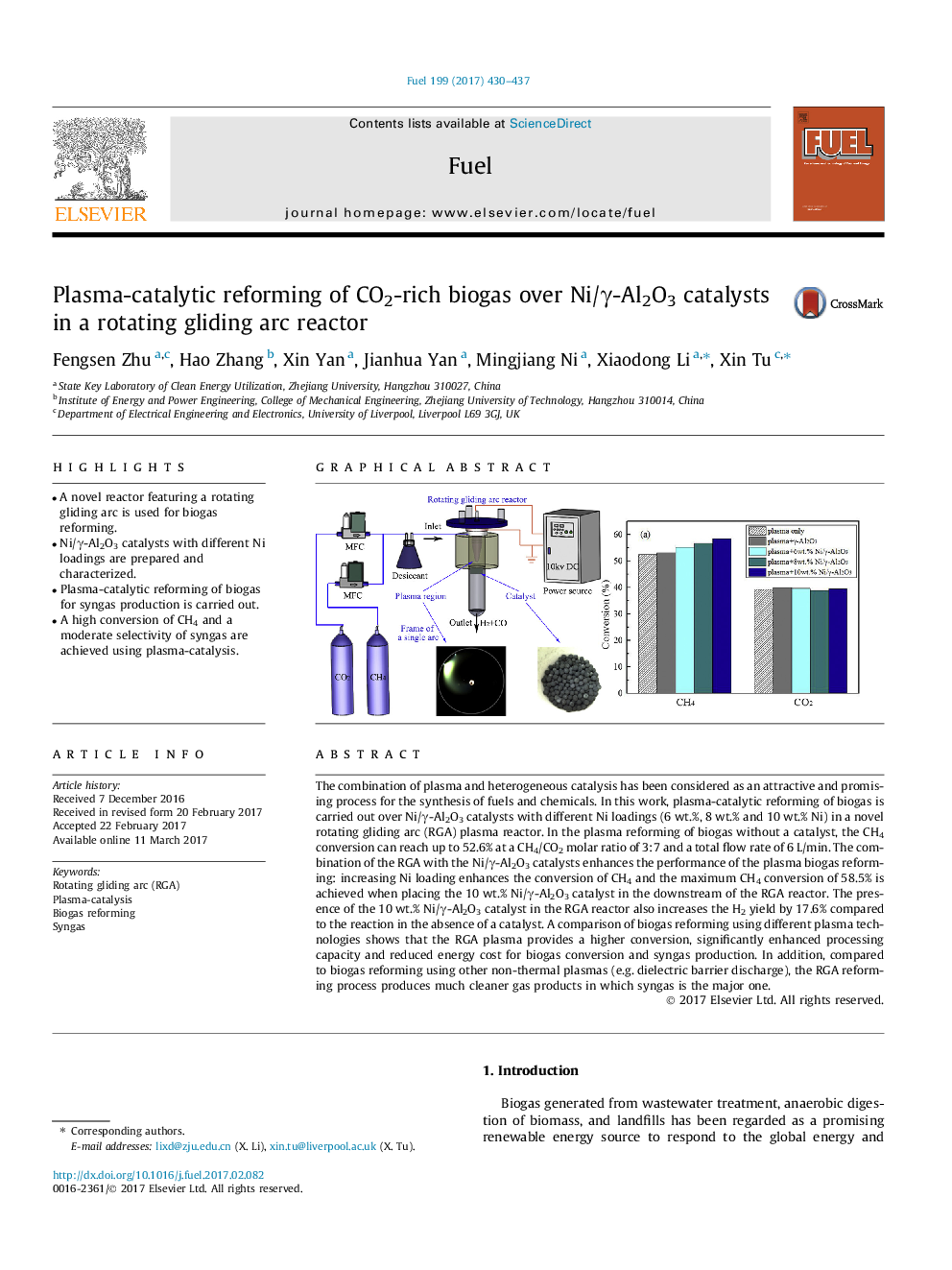

â¢A novel reactor featuring a rotating gliding arc is used for biogas reforming.â¢Ni/γ-Al2O3 catalysts with different Ni loadings are prepared and characterized.â¢Plasma-catalytic reforming of biogas for syngas production is carried out.â¢A high conversion of CH4 and a moderate selectivity of syngas are achieved using plasma-catalysis.

The combination of plasma and heterogeneous catalysis has been considered as an attractive and promising process for the synthesis of fuels and chemicals. In this work, plasma-catalytic reforming of biogas is carried out over Ni/γ-Al2O3 catalysts with different Ni loadings (6 wt.%, 8 wt.% and 10 wt.% Ni) in a novel rotating gliding arc (RGA) plasma reactor. In the plasma reforming of biogas without a catalyst, the CH4 conversion can reach up to 52.6% at a CH4/CO2 molar ratio of 3:7 and a total flow rate of 6 L/min. The combination of the RGA with the Ni/γ-Al2O3 catalysts enhances the performance of the plasma biogas reforming: increasing Ni loading enhances the conversion of CH4 and the maximum CH4 conversion of 58.5% is achieved when placing the 10 wt.% Ni/γ-Al2O3 catalyst in the downstream of the RGA reactor. The presence of the 10 wt.% Ni/γ-Al2O3 catalyst in the RGA reactor also increases the H2 yield by 17.6% compared to the reaction in the absence of a catalyst. A comparison of biogas reforming using different plasma technologies shows that the RGA plasma provides a higher conversion, significantly enhanced processing capacity and reduced energy cost for biogas conversion and syngas production. In addition, compared to biogas reforming using other non-thermal plasmas (e.g. dielectric barrier discharge), the RGA reforming process produces much cleaner gas products in which syngas is the major one.

Graphical abstractDownload high-res image (117KB)Download full-size image