| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 6474990 | Fuel | 2017 | 7 Pages |

â¢Mesoporous LaNiO3 perovskite was synthesized by modified nanocasting method.â¢The enhanced surface area contributed to higher dispersity and smaller Ni particles.â¢More active sites afforded superior catalytic activity and stability.â¢Mesoporous perovskite showed outstanding resistance to coking and sintering.

A type of order mesoporous LaNiO3 perovskite oxide was synthesized employing SBA-15 as hard template. Compared with conventional LaNiO3 perovskite prepared by citrate method, the modified nanocasting method with aid of ultraphonic and vacumm could deliver more precursors into the channels and reduce residual at external surface of template, resulting in forming high order mesoporous structure. The properties of mesoporous perovskite catalyst were characterized by TEM, XRD, H2-TPR, TGA and N2 adsorption-desorption techniques. By tracing amounts of CH4, CO and H2 observed in the partial oxidation of methane to syngas system, the activity and stability of both catalysts were evaluated at different temperatures and space velocity. LaNiO3 catalyst synthesized by modified nanocasting method with order mesoporous structure showed superior catalytic performance and less carbon deposition than the conventional counterpart, giving higher CH4 conversion of 96% at 800 °C than counterpart (82%). The result was attributed to enhanced surface area, higher metal dispersion and smaller size of Ni particle derived from highly order meso-structure.

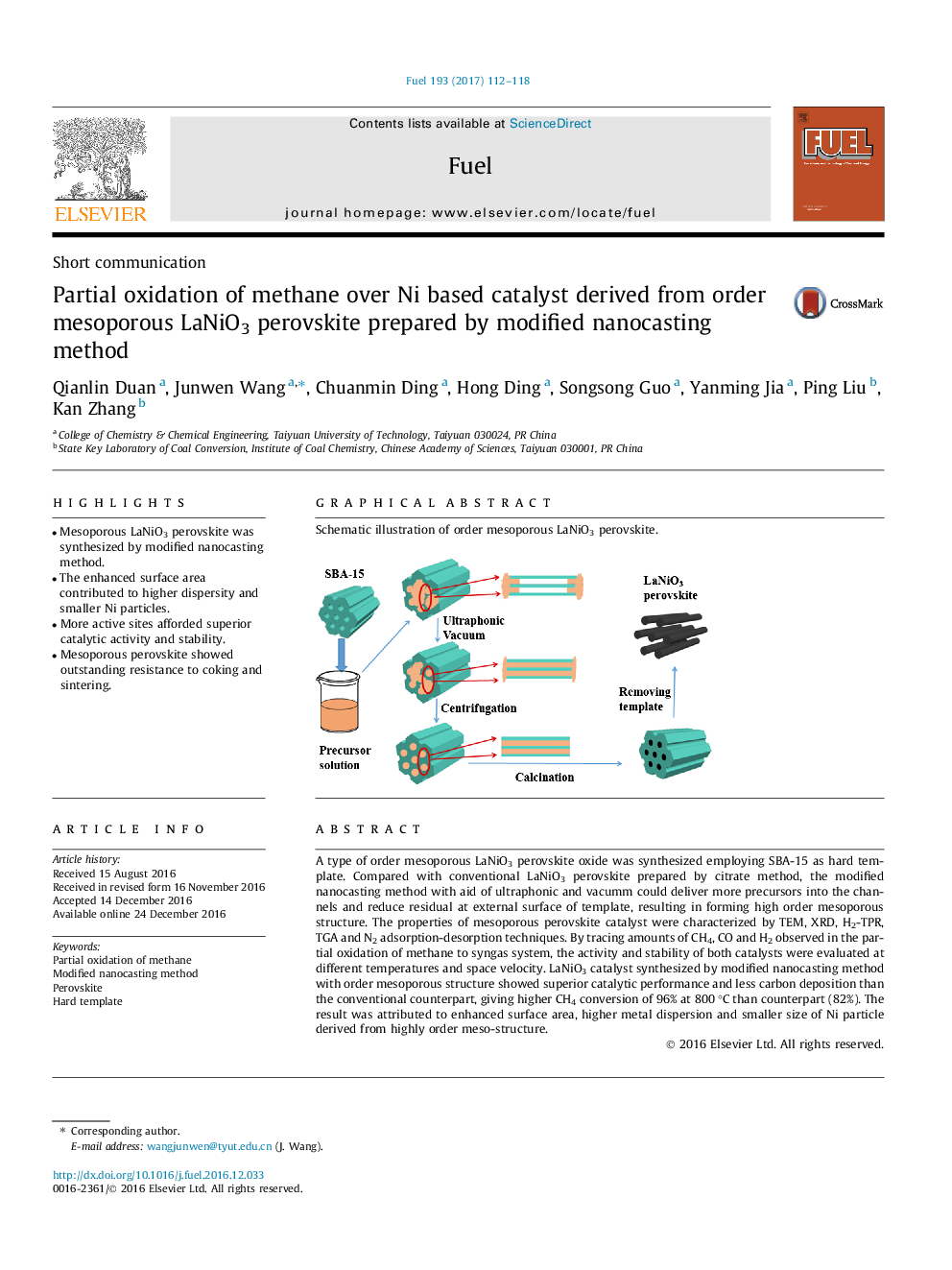

Graphical abstractSchematic illustration of order mesoporous LaNiO3 perovskite.Download high-res image (77KB)Download full-size image