| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 6475631 | Fuel | 2017 | 13 Pages |

â¢Reactions involving asphaltenes are not main contributors to endothermic trends.â¢Mixing enhanced free radical polymerization and led to higher TI and viscosity.â¢Deasphalting a feedstock shifts the reactions to produce more overall asphaltenes.â¢Asphaltenes tendency to precipitate at higher pressure contributed to more TI.

Thermal cracking of Athabasca vacuum residue (AVR) and Athabasca bitumen (AB) and their maltene fraction was investigated at 400 °C in a closed system, i.e. autoclave. The effect of the following variables on the product yield and the properties of the liquid fraction and its maltene extract was evaluated: residence time, pressure of the reactor unit, stirring, temperature and asphaltenes content of the feedstock. The yield of the different fractions, the total energy consumption, the pressure buildup in the batch reactor and the °API gravity and viscosity of the liquid fraction and its maltene extract were used to evaluate the impact of a given parameter. In addition, high-temperature simulated distillation (HTSD) analysis of the liquid product and gas chromatography (GC) analysis for gas product were performed. The effect of reaction time, mixing and pressure on the yield of toluene insolubles (TI) depended on the presence of asphaltenes in the feedstock. TI yield increased at the expense of the asphaltenic fraction when reaction time, mixing and pressure increased. There is an inverse relationship between the initial asphaltenes content in the feedstock and the overall asphaltenes yield base on the parent feedstock. Moreover, increasing asphaltenes content of the feedstock did not introduce significant changes in the total energy input to the reactor.

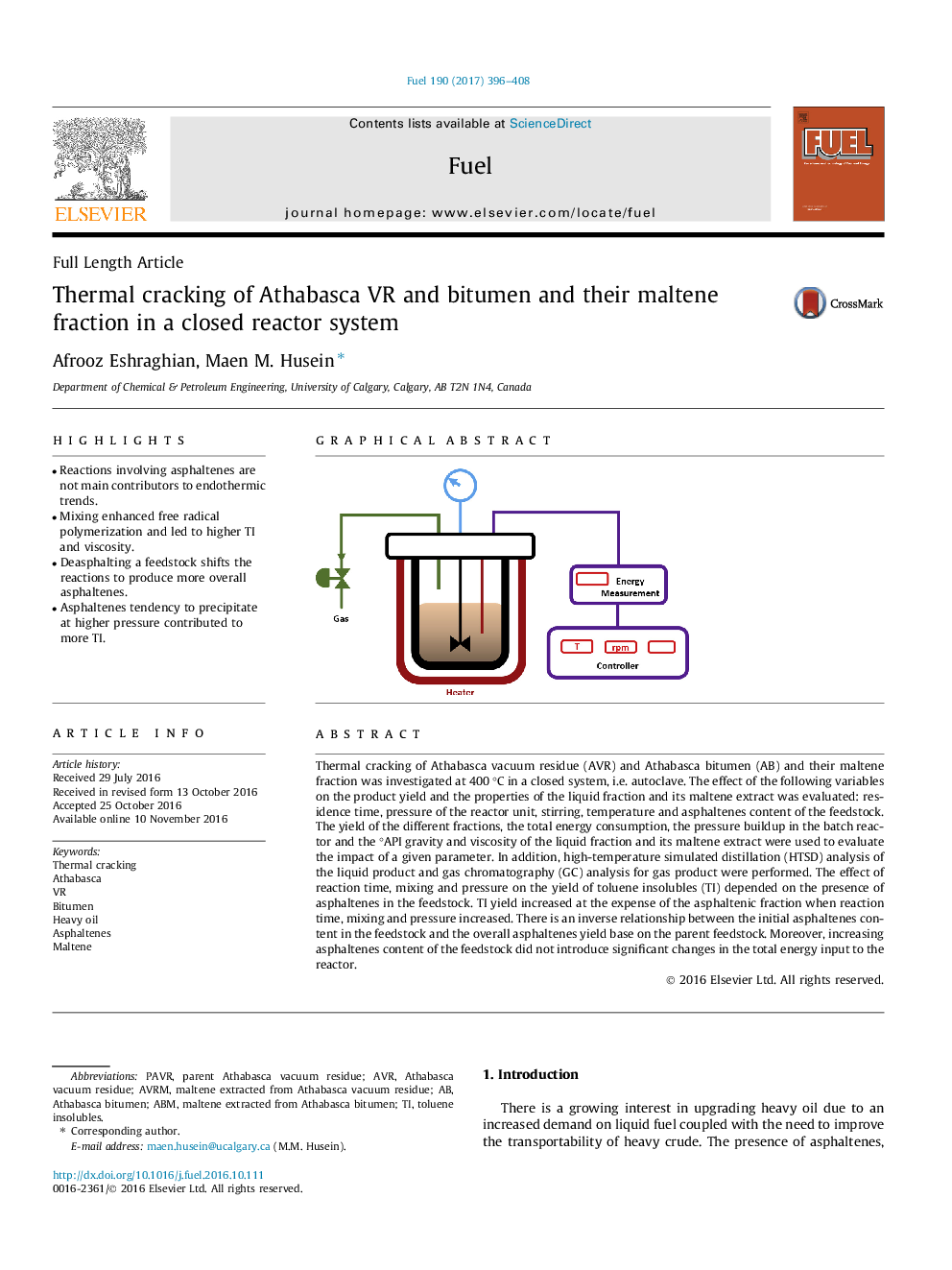

Graphical abstractDownload full-size image