| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 6475969 | Fuel | 2017 | 10 Pages |

â¢MgO-based sorbents were pelleted using an extrusion-spheronization method.â¢The physicochemical properties of the sorbents were changed during pelletization.â¢The pelletization process can improve the performance of NaNO3 doped sorbents.â¢After pelletization, the sorbents only doped with Na2CO3 would perform worse.

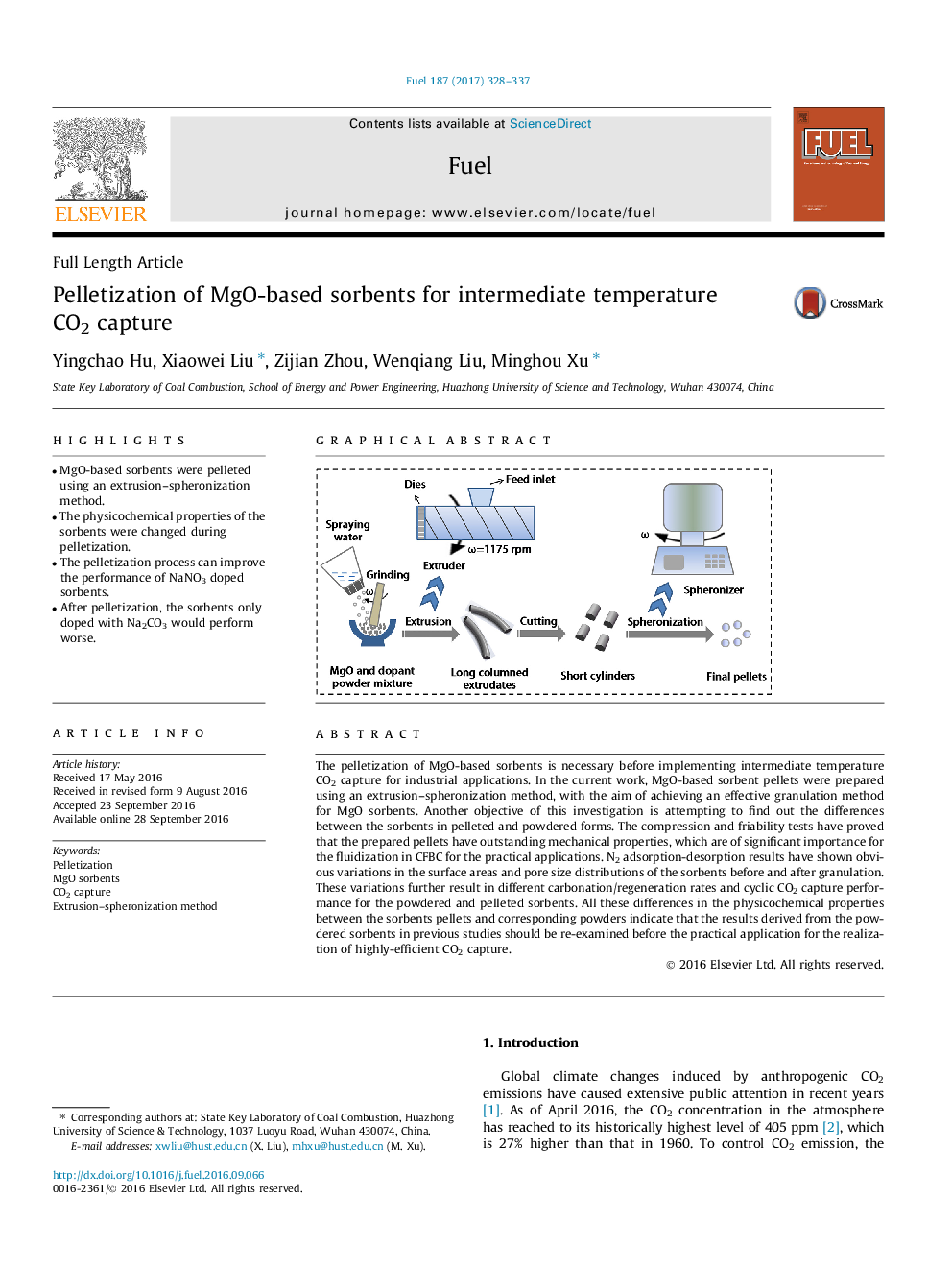

The pelletization of MgO-based sorbents is necessary before implementing intermediate temperature CO2 capture for industrial applications. In the current work, MgO-based sorbent pellets were prepared using an extrusion-spheronization method, with the aim of achieving an effective granulation method for MgO sorbents. Another objective of this investigation is attempting to find out the differences between the sorbents in pelleted and powdered forms. The compression and friability tests have proved that the prepared pellets have outstanding mechanical properties, which are of significant importance for the fluidization in CFBC for the practical applications. N2 adsorption-desorption results have shown obvious variations in the surface areas and pore size distributions of the sorbents before and after granulation. These variations further result in different carbonation/regeneration rates and cyclic CO2 capture performance for the powdered and pelleted sorbents. All these differences in the physicochemical properties between the sorbents pellets and corresponding powders indicate that the results derived from the powdered sorbents in previous studies should be re-examined before the practical application for the realization of highly-efficient CO2 capture.

Graphical abstractDownload high-res image (166KB)Download full-size image