| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 6480880 | Construction and Building Materials | 2017 | 7 Pages |

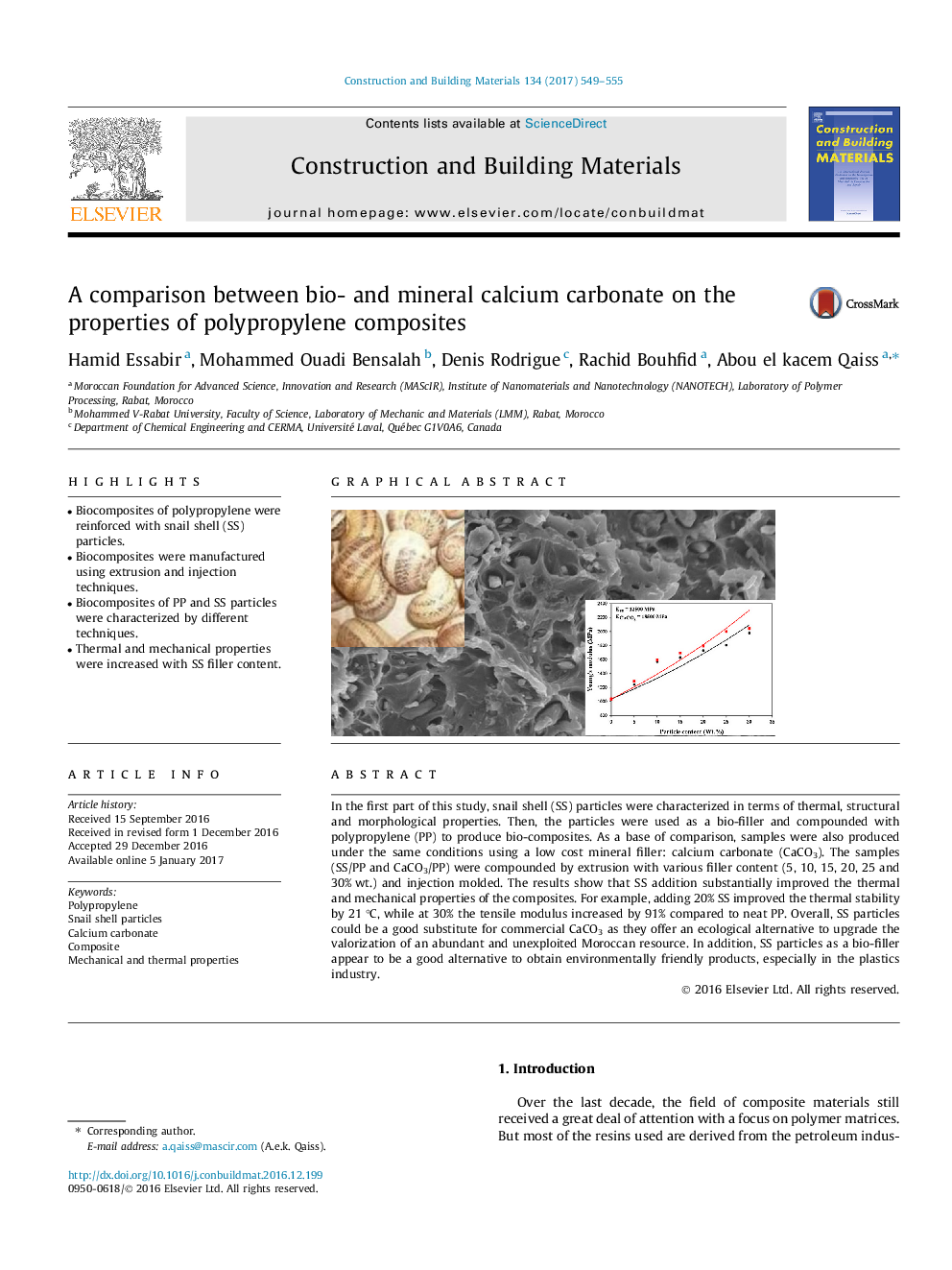

â¢Biocomposites of polypropylene were reinforced with snail shell (SS) particles.â¢Biocomposites were manufactured using extrusion and injection techniques.â¢Biocomposites of PP and SS particles were characterized by different techniques.â¢Thermal and mechanical properties were increased with SS filler content.

In the first part of this study, snail shell (SS) particles were characterized in terms of thermal, structural and morphological properties. Then, the particles were used as a bio-filler and compounded with polypropylene (PP) to produce bio-composites. As a base of comparison, samples were also produced under the same conditions using a low cost mineral filler: calcium carbonate (CaCO3). The samples (SS/PP and CaCO3/PP) were compounded by extrusion with various filler content (5, 10, 15, 20, 25 and 30% wt.) and injection molded. The results show that SS addition substantially improved the thermal and mechanical properties of the composites. For example, adding 20% SS improved the thermal stability by 21 °C, while at 30% the tensile modulus increased by 91% compared to neat PP. Overall, SS particles could be a good substitute for commercial CaCO3 as they offer an ecological alternative to upgrade the valorization of an abundant and unexploited Moroccan resource. In addition, SS particles as a bio-filler appear to be a good alternative to obtain environmentally friendly products, especially in the plastics industry.

Graphical abstractDownload high-res image (194KB)Download full-size image