| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 679351 | Bioresource Technology | 2016 | 9 Pages |

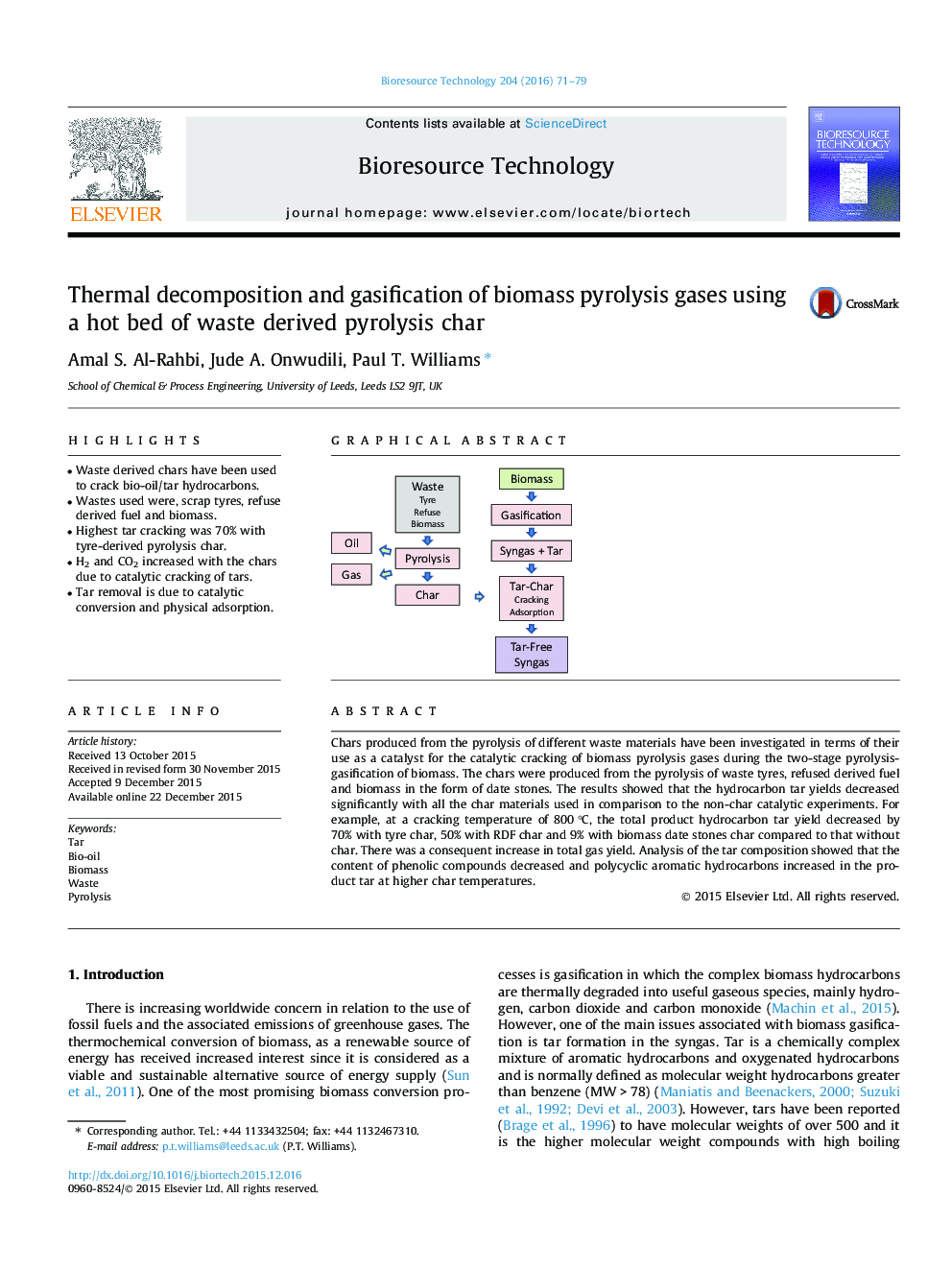

•Waste derived chars have been used to crack bio-oil/tar hydrocarbons.•Wastes used were, scrap tyres, refuse derived fuel and biomass.•Highest tar cracking was 70% with tyre-derived pyrolysis char.•H2 and CO2 increased with the chars due to catalytic cracking of tars.•Tar removal is due to catalytic conversion and physical adsorption.

Chars produced from the pyrolysis of different waste materials have been investigated in terms of their use as a catalyst for the catalytic cracking of biomass pyrolysis gases during the two-stage pyrolysis-gasification of biomass. The chars were produced from the pyrolysis of waste tyres, refused derived fuel and biomass in the form of date stones. The results showed that the hydrocarbon tar yields decreased significantly with all the char materials used in comparison to the non-char catalytic experiments. For example, at a cracking temperature of 800 °C, the total product hydrocarbon tar yield decreased by 70% with tyre char, 50% with RDF char and 9% with biomass date stones char compared to that without char. There was a consequent increase in total gas yield. Analysis of the tar composition showed that the content of phenolic compounds decreased and polycyclic aromatic hydrocarbons increased in the product tar at higher char temperatures.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide