| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 679826 | Bioresource Technology | 2015 | 8 Pages |

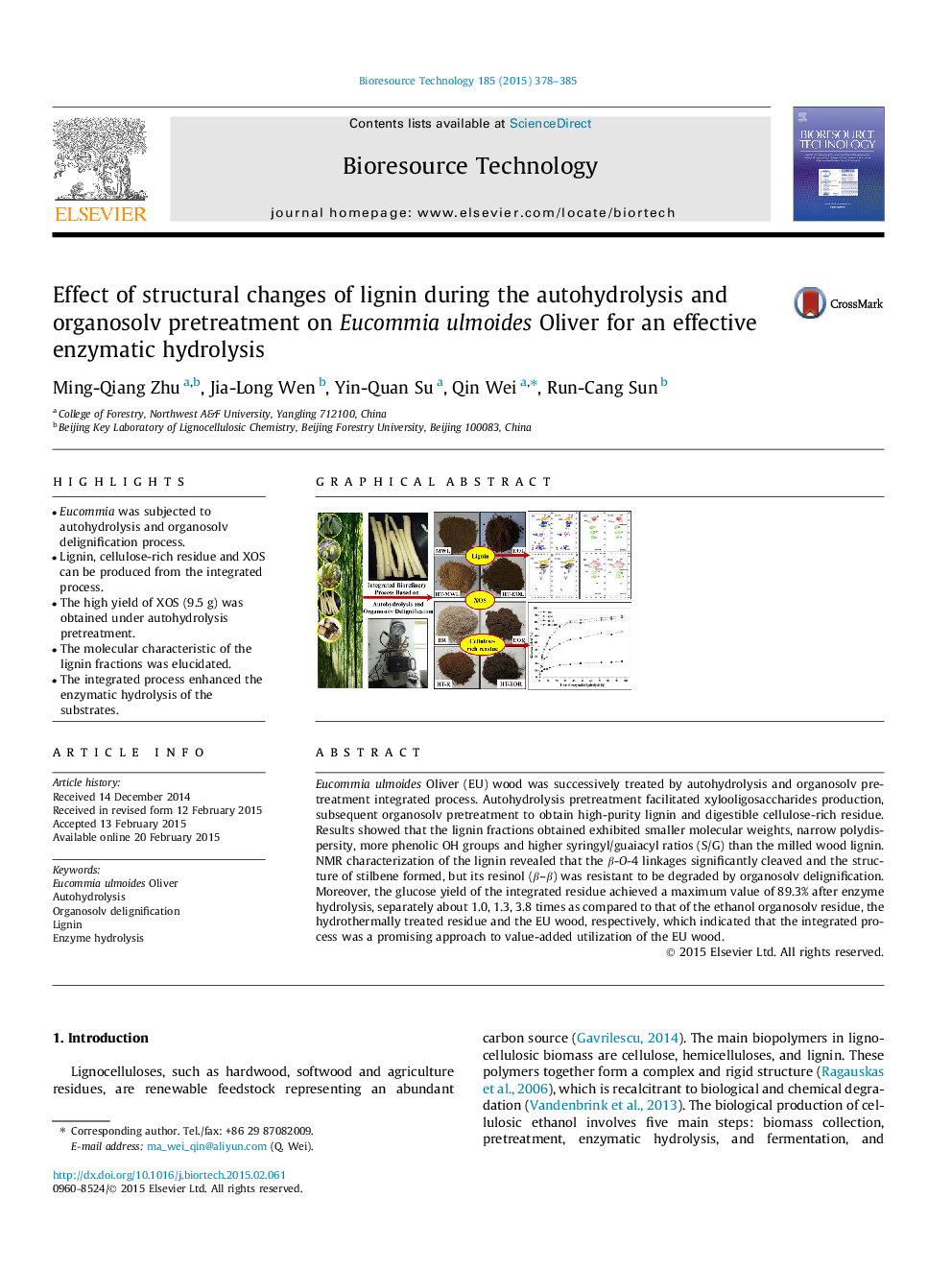

•Eucommia was subjected to autohydrolysis and organosolv delignification process.•Lignin, cellulose-rich residue and XOS can be produced from the integrated process.•The high yield of XOS (9.5 g) was obtained under autohydrolysis pretreatment.•The molecular characteristic of the lignin fractions was elucidated.•The integrated process enhanced the enzymatic hydrolysis of the substrates.

Eucommia ulmoides Oliver (EU) wood was successively treated by autohydrolysis and organosolv pretreatment integrated process. Autohydrolysis pretreatment facilitated xylooligosaccharides production, subsequent organosolv pretreatment to obtain high-purity lignin and digestible cellulose-rich residue. Results showed that the lignin fractions obtained exhibited smaller molecular weights, narrow polydispersity, more phenolic OH groups and higher syringyl/guaiacyl ratios (S/G) than the milled wood lignin. NMR characterization of the lignin revealed that the β-O-4 linkages significantly cleaved and the structure of stilbene formed, but its resinol (β–β) was resistant to be degraded by organosolv delignification. Moreover, the glucose yield of the integrated residue achieved a maximum value of 89.3% after enzyme hydrolysis, separately about 1.0, 1.3, 3.8 times as compared to that of the ethanol organosolv residue, the hydrothermally treated residue and the EU wood, respectively, which indicated that the integrated process was a promising approach to value-added utilization of the EU wood.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide