| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 680337 | Bioresource Technology | 2015 | 5 Pages |

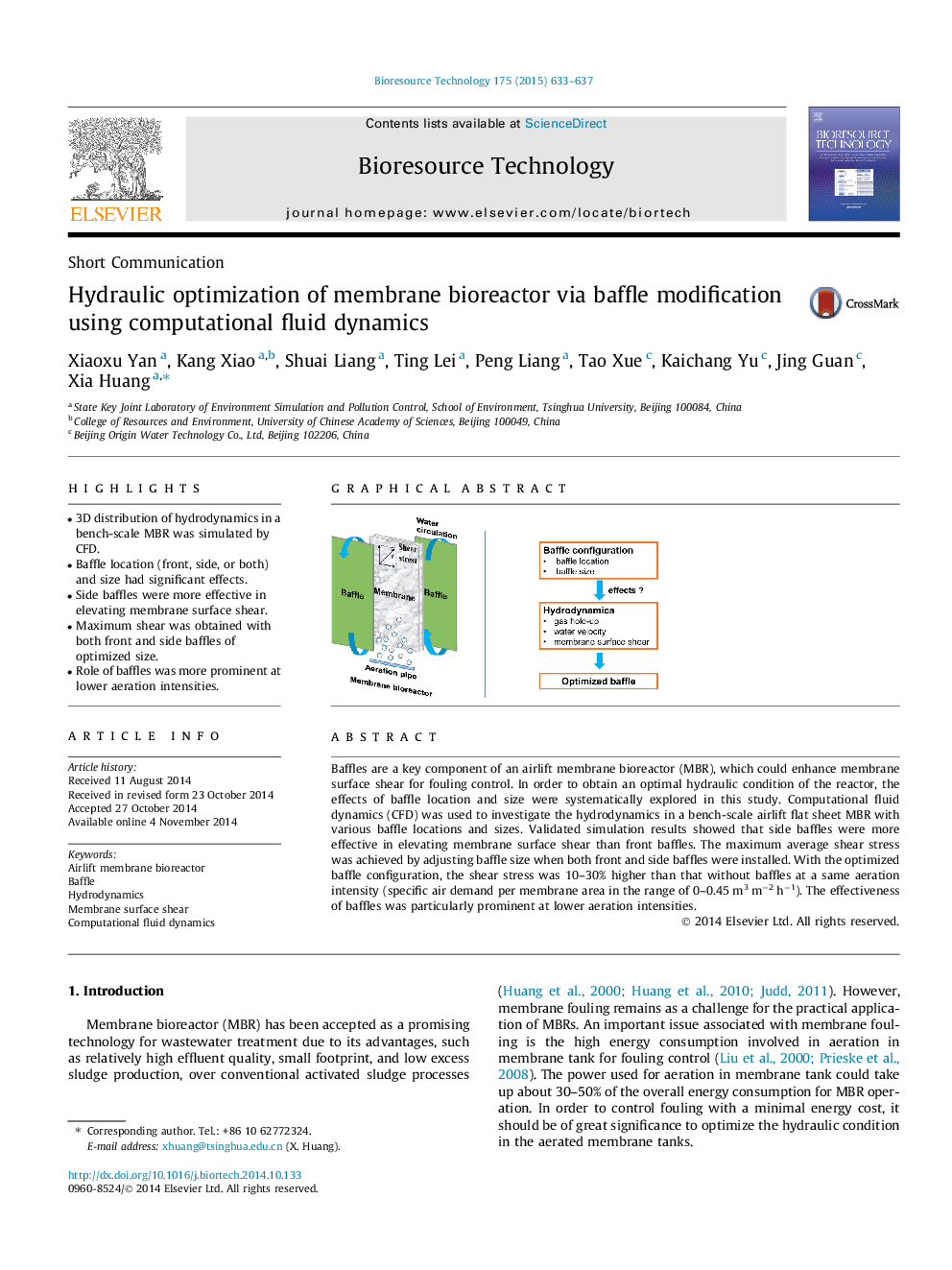

•3D distribution of hydrodynamics in a bench-scale MBR was simulated by CFD.•Baffle location (front, side, or both) and size had significant effects.•Side baffles were more effective in elevating membrane surface shear.•Maximum shear was obtained with both front and side baffles of optimized size.•Role of baffles was more prominent at lower aeration intensities.

Baffles are a key component of an airlift membrane bioreactor (MBR), which could enhance membrane surface shear for fouling control. In order to obtain an optimal hydraulic condition of the reactor, the effects of baffle location and size were systematically explored in this study. Computational fluid dynamics (CFD) was used to investigate the hydrodynamics in a bench-scale airlift flat sheet MBR with various baffle locations and sizes. Validated simulation results showed that side baffles were more effective in elevating membrane surface shear than front baffles. The maximum average shear stress was achieved by adjusting baffle size when both front and side baffles were installed. With the optimized baffle configuration, the shear stress was 10–30% higher than that without baffles at a same aeration intensity (specific air demand per membrane area in the range of 0–0.45 m3 m−2 h−1). The effectiveness of baffles was particularly prominent at lower aeration intensities.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide