| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 680475 | Bioresource Technology | 2014 | 6 Pages |

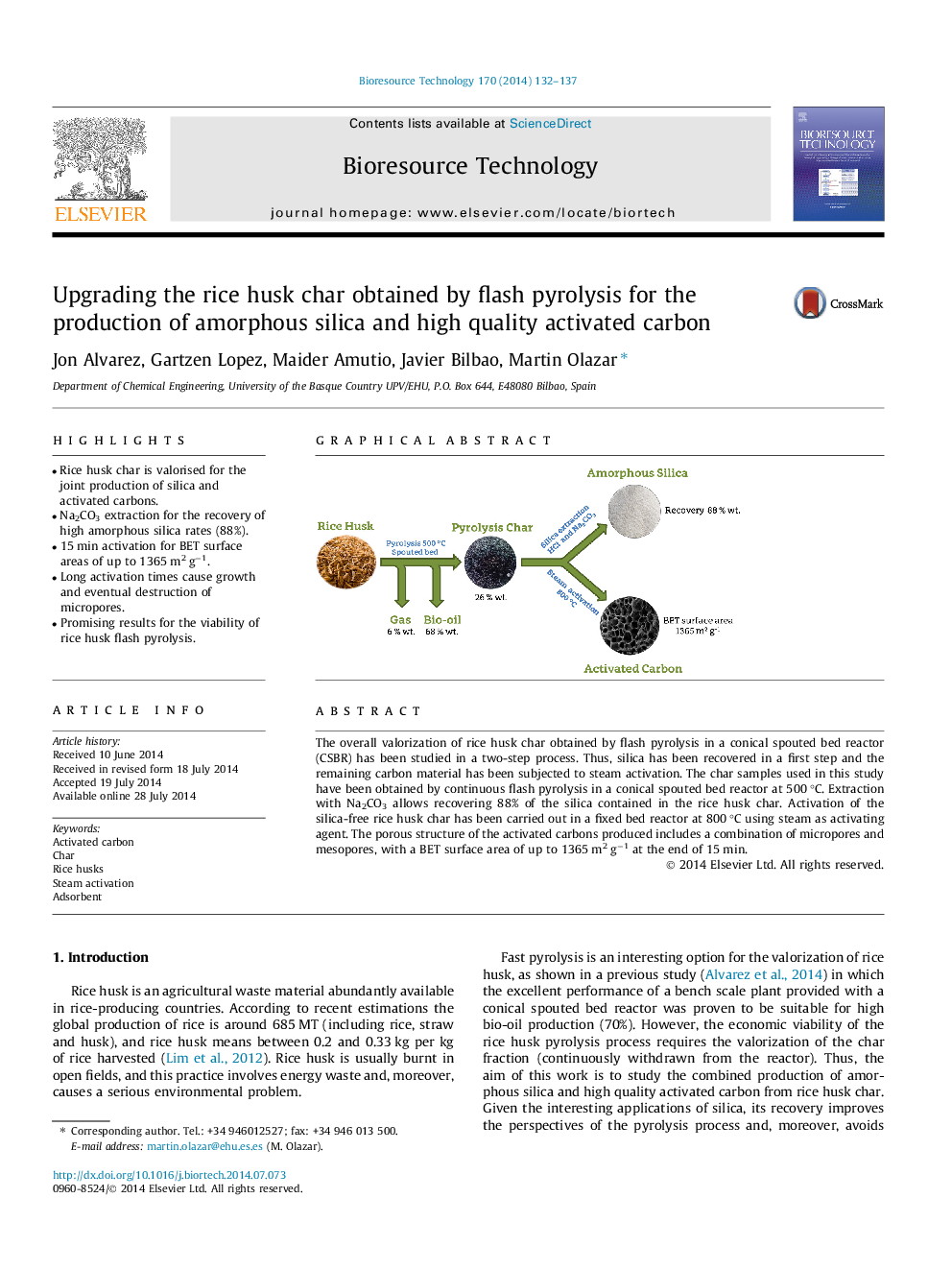

•Rice husk char is valorised for the joint production of silica and activated carbons.•Na2CO3 extraction for the recovery of high amorphous silica rates (88%).•15 min activation for BET surface areas of up to 1365 m2 g−1.•Long activation times cause growth and eventual destruction of micropores.•Promising results for the viability of rice husk flash pyrolysis.

The overall valorization of rice husk char obtained by flash pyrolysis in a conical spouted bed reactor (CSBR) has been studied in a two-step process. Thus, silica has been recovered in a first step and the remaining carbon material has been subjected to steam activation. The char samples used in this study have been obtained by continuous flash pyrolysis in a conical spouted bed reactor at 500 °C. Extraction with Na2CO3 allows recovering 88% of the silica contained in the rice husk char. Activation of the silica-free rice husk char has been carried out in a fixed bed reactor at 800 °C using steam as activating agent. The porous structure of the activated carbons produced includes a combination of micropores and mesopores, with a BET surface area of up to 1365 m2 g−1 at the end of 15 min.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide