| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 680860 | Bioresource Technology | 2014 | 8 Pages |

•An example of BES scaling up is shown on a technical scale microbial electrolysis cell.•Efficient COD removal and current production is achieved.•A multitude of parameters influences the scaling-up.•A model for system comparison is introduced.

This study focuses on the challenges of the scaling up process of bioelectrochemical systems on the example of a technical scale microbial electrolysis cell referred to as the “prototype”. Anodically treating real wastewater and operated in continuous mode at a hydraulic retention time of 1.23 d with an average chemical oxygen demand (COD)-loading rate of 0.5 g O2 d−1 LReactor−1 the prototype on average showed COD removal efficiency of 67% with effluent concentrations of 210 mg O2 L−1 and an ammonium elimination rate of 17.8 ± 3.9 mg N d−1 LReactor−1 resulting in effluent concentrations of 30.7 ± 3.7 mg N L−1 with a removal efficiency of 40% at a current generation of 72 μA cm−2 and Coulomb efficiency of 11%. A model is described as a method for comparing conventional and BES based technology using the above mentioned criteria and balancing them against the respective loading rates.

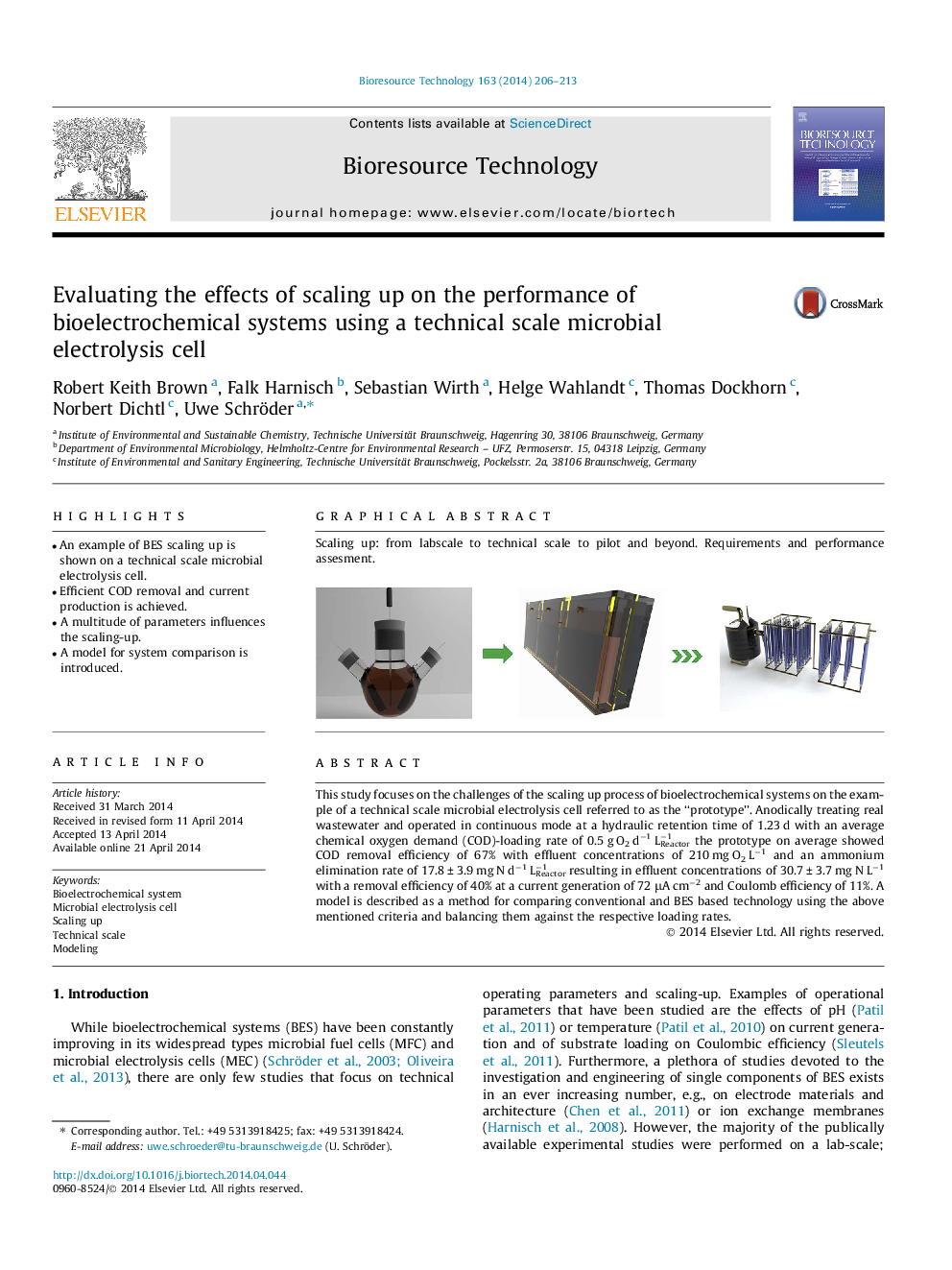

Graphical abstractScaling up: from labscale to technical scale to pilot and beyond. Requirements and performance assesment.Figure optionsDownload full-size imageDownload as PowerPoint slide