| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 709375 | IFAC Proceedings Volumes | 2013 | 6 Pages |

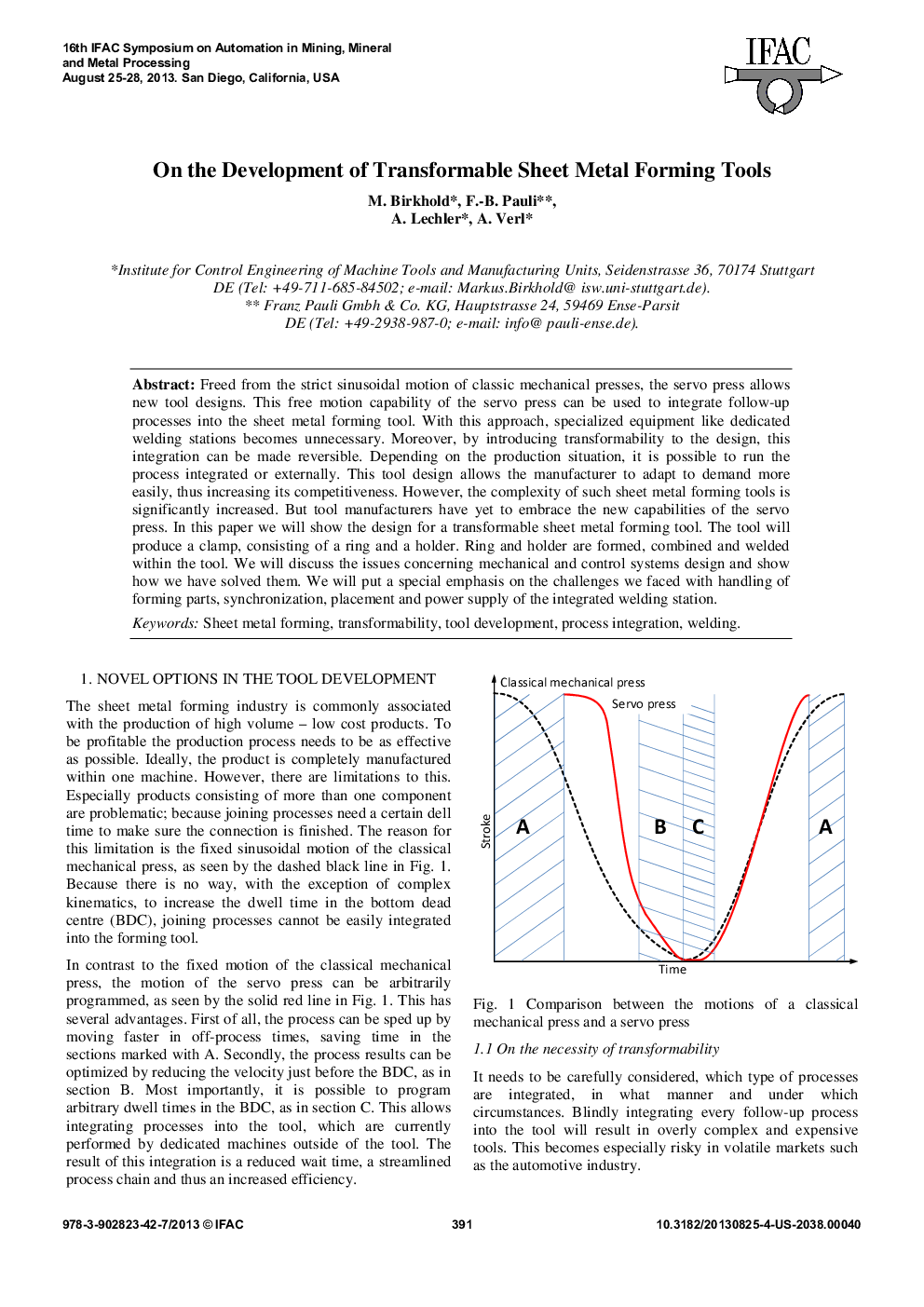

Freed from the strict sinusoidal motion of classic mechanical presses, the servo press allows new tool designs. This free motion capability of the servo press can be used to integrate follow-up processes into the sheet metal forming tool. With this approach, specialized equipment like dedicated welding stations becomes unnecessary. Moreover, by introducing transformability to the design, this integration can be made reversible. Depending on the production situation, it is possible to run the process integrated or externally. This tool design allows the manufacturer to adapt to demand more easily, thus increasing its competitiveness. However, the complexity of such sheet metal forming tools is significantly increased. But tool manufacturers have yet to embrace the new capabilities of the servo press. In this paper we will show the design for a transformable sheet metal forming tool. The tool will produce a clamp, consisting of a ring and a holder. Ring and holder are formed, combined and welded within the tool. We will discuss the issues concerning mechanical and control systems design and show how we have solved them. We will put a special emphasis on the challenges we faced with handling of forming parts, synchronization, placement and power supply of the integrated welding station.