| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 710270 | IFAC Proceedings Volumes | 2009 | 6 Pages |

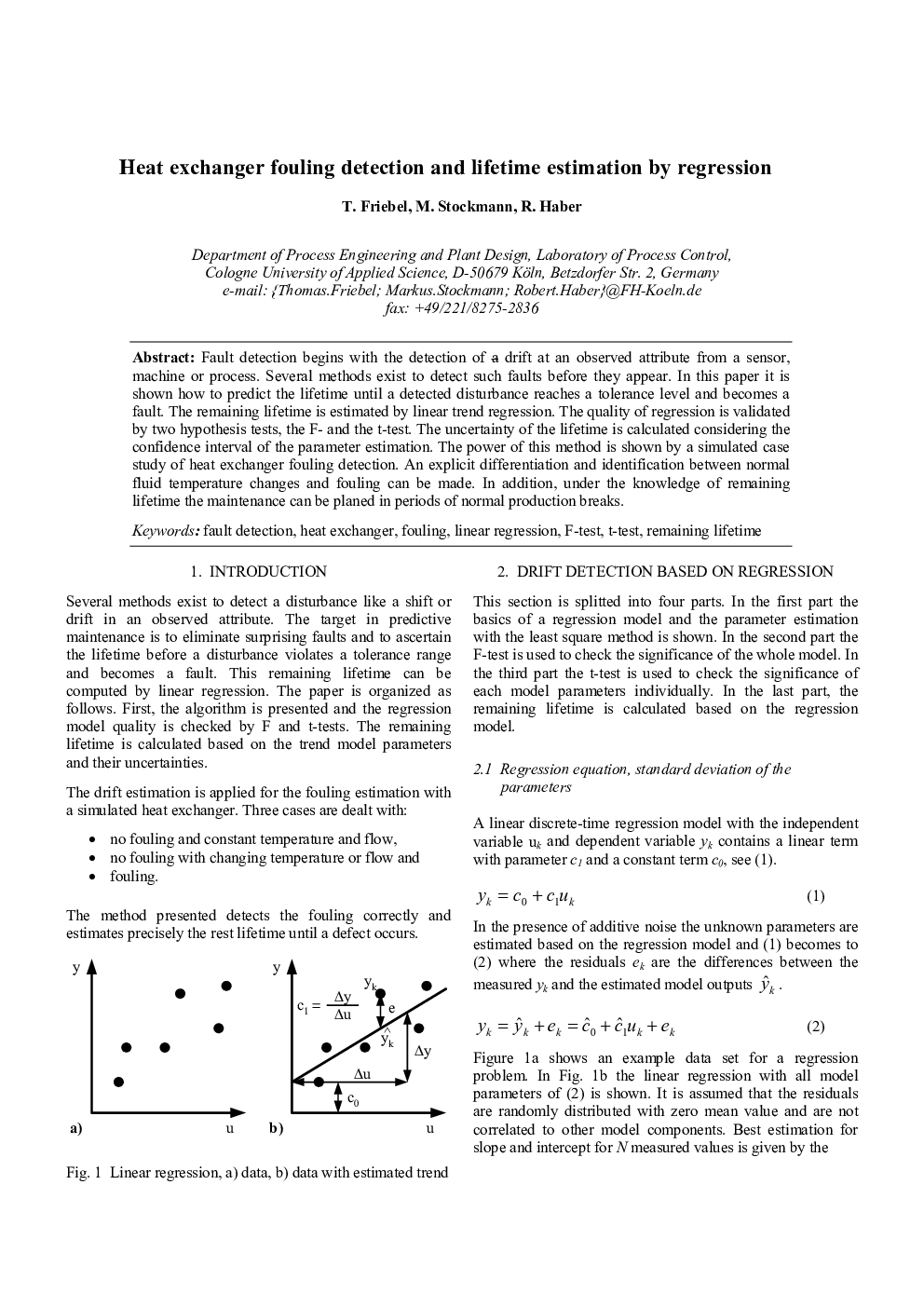

AbstractFault detection begins with the detection of a drift at an observed attribute from a sensor, machine or process. Several methods exist to detect such faults before they appear. In this paper it is shown how to predict the lifetime until a detected disturbance reaches a tolerance level and becomes a fault. The remaining lifetime is estimated by linear trend regression. The quality of regression is validated by two hypothesis tests, the F- and the t-test. The uncertainty of the lifetime is calculated considering the confidence interval of the parameter estimation. The power of this method is shown by a simulated case study of heat exchanger fouling detection. An explicit differentiation and identification between normal fluid temperature changes and fouling can be made. In addition, under the knowledge of remaining lifetime the maintenance can be planed in periods of normal production breaks.