| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 710711 | IFAC Proceedings Volumes | 2009 | 6 Pages |

Abstract

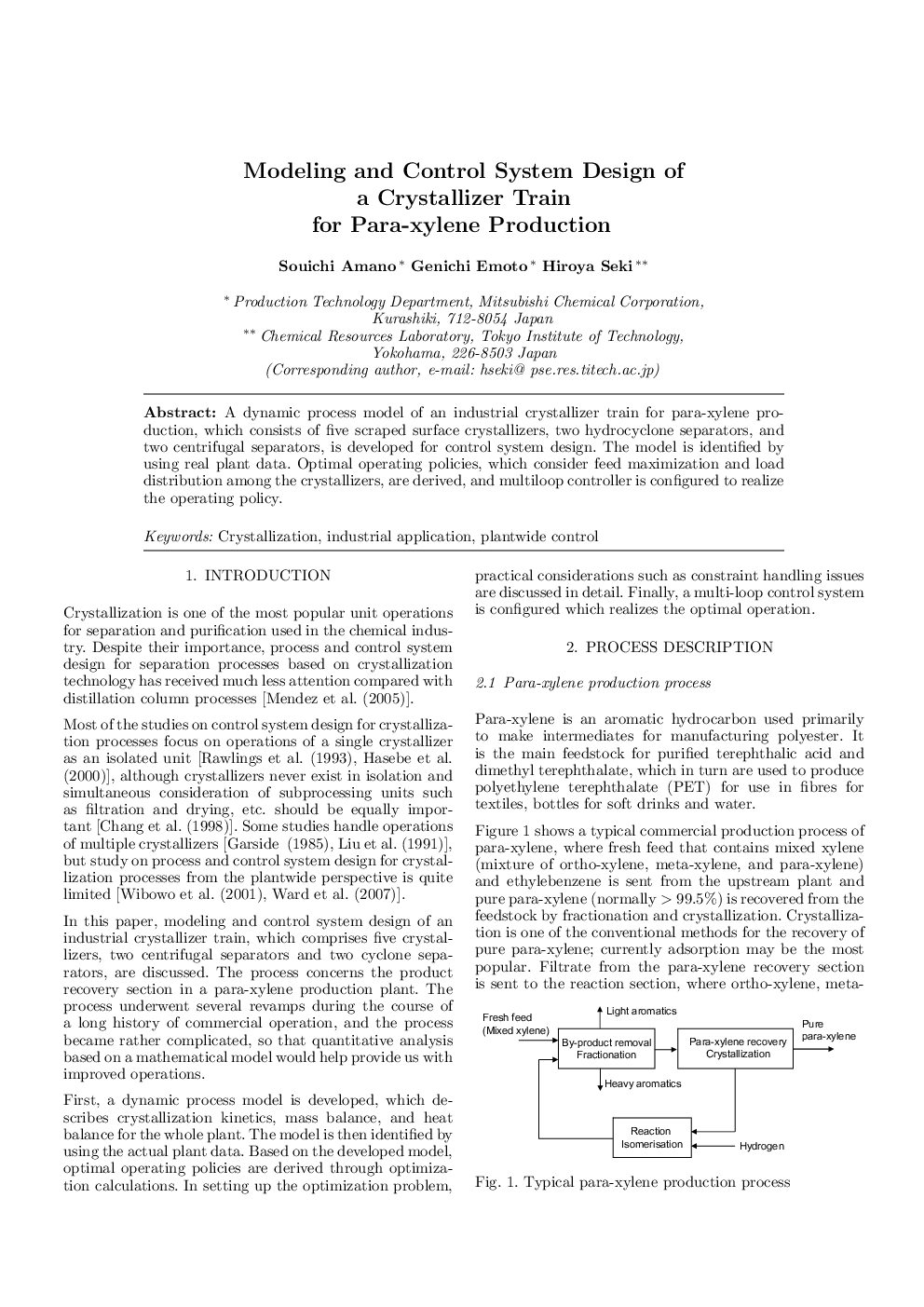

AbstractA dynamic process model of an industrial crystallizer train for para-xylene production, which consists of five scraped surface crystallizers, two hydrocyclone separators, and two centrifugal separators, is developed for control system design. The model is identified by using real plant data. Optimal operating policies, which consider feed maximization and load distribution among the crystallizers, are derived, and multiloop controller is configured to realize the operating policy.

Related Topics

Physical Sciences and Engineering

Engineering

Computational Mechanics

Authors

Souichi Amano, Genichi Emoto, Hiroya Seki,