| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 713217 | IFAC-PapersOnLine | 2015 | 5 Pages |

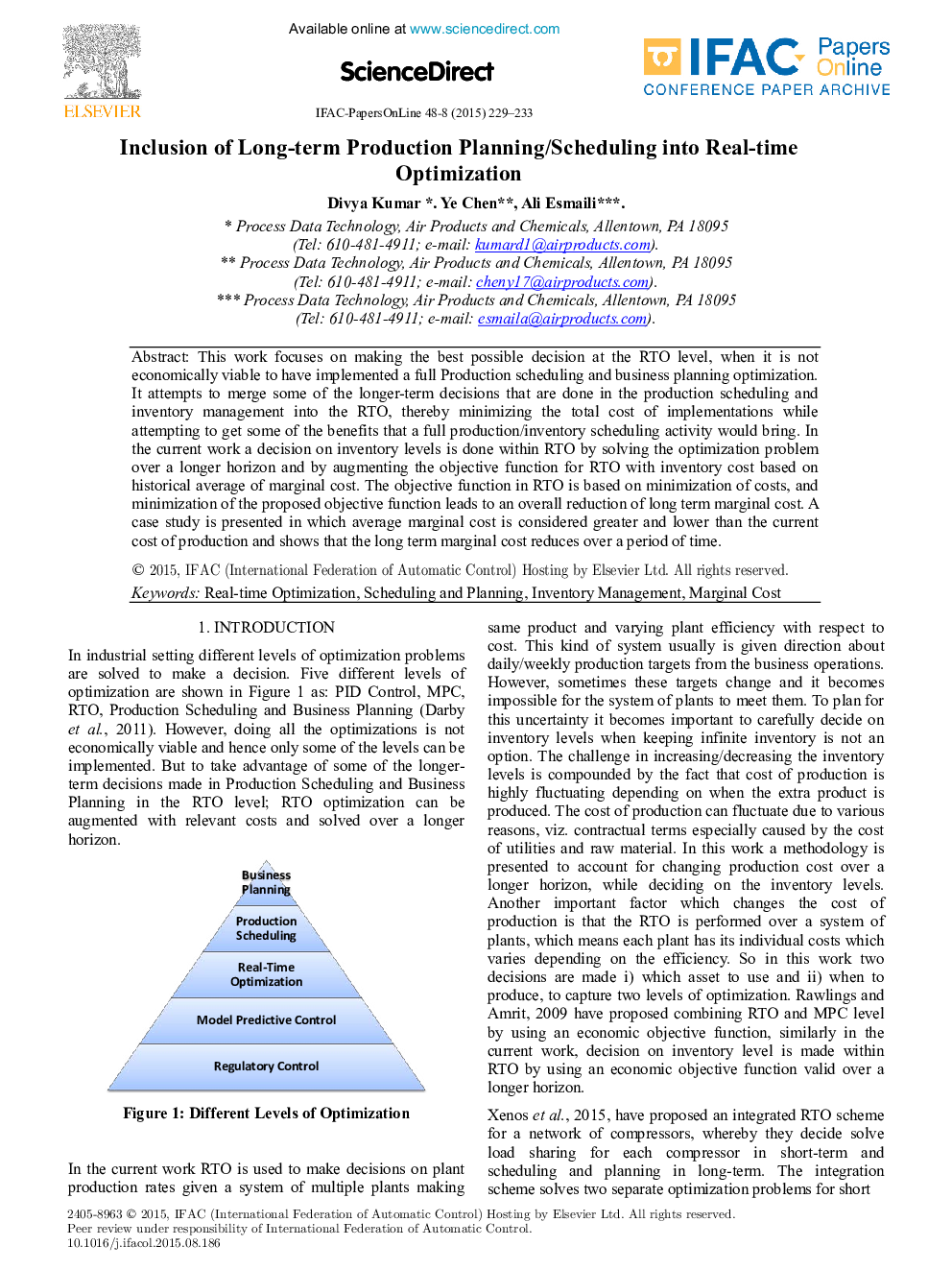

This work focuses on making the best possible decision at the RTO level, when it is not economically viable to have implemented a full Production scheduling and business planning optimization. It attempts to merge some of the longer-term decisions that are done in the production scheduling and inventory management into the RTO, thereby minimizing the total cost of implementations while attempting to get some of the benefits that a full production/inventory scheduling activity would bring. In the current work a decision on inventory levels is done within RTO by solving the optimization problem over a longer horizon and by augmenting the objective function for RTO with inventory cost based on historical average of marginal cost. The objective function in RTO is based on minimization of costs, and minimization of the proposed objective function leads to an overall reduction of long term marginal cost. A case study is presented in which average marginal cost is considered greater and lower than the current cost of production and shows that the long term marginal cost reduces over a period of time.