| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 713241 | IFAC-PapersOnLine | 2015 | 6 Pages |

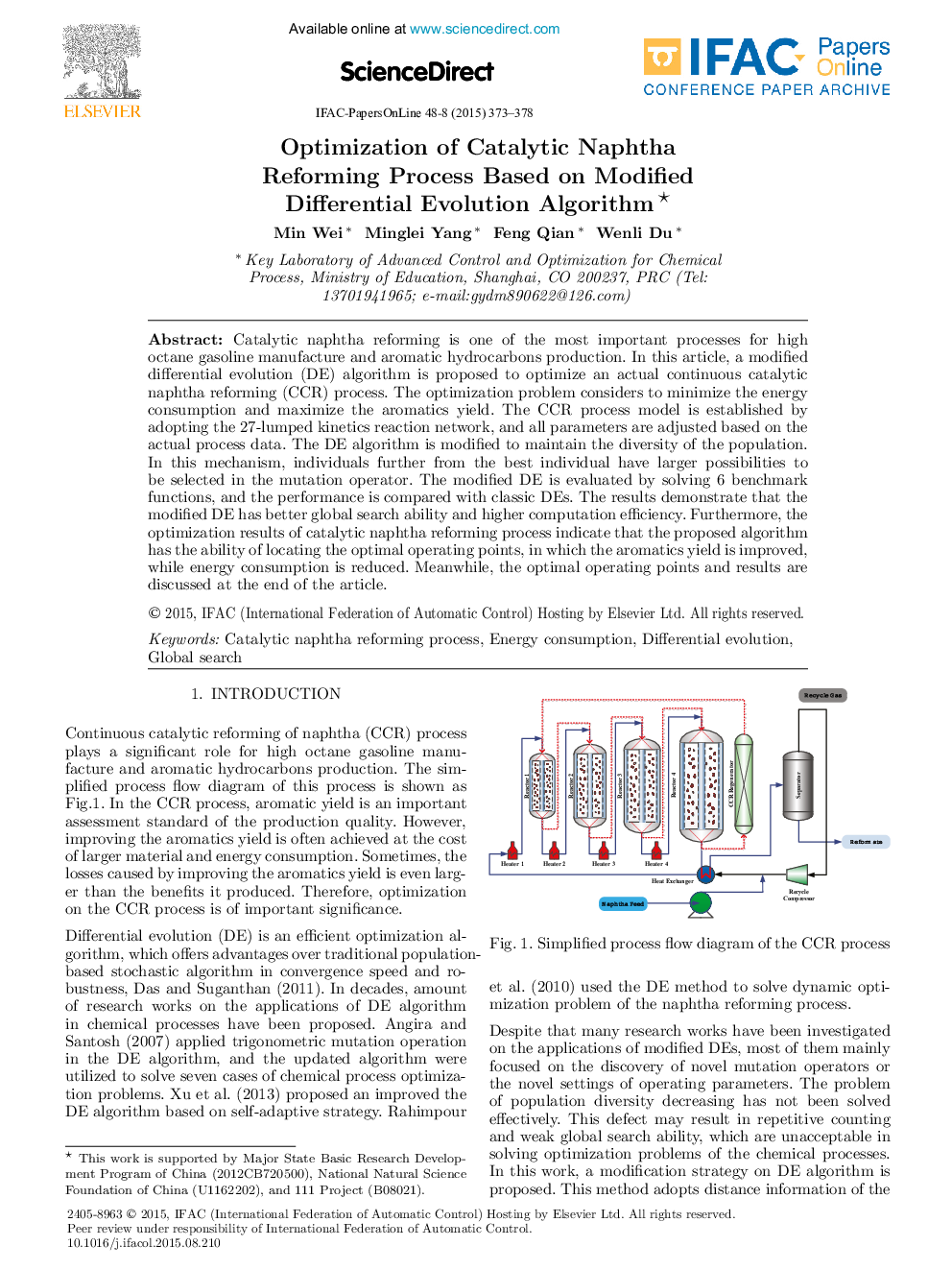

Catalytic naphtha reforming is one of the most important processes for high octane gasoline manufacture and aromatic hydrocarbons production. In this article, a modified differential evolution (DE) algorithm is proposed to optimize an actual continuous catalytic naphtha reforming (CCR) process. The optimization problem considers to minimize the energy consumption and maximize the aromatics yield. The CCR process model is established by adopting the 27-lumped kinetics reaction network, and all parameters are adjusted based on the actual process data. The DE algorithm is modified to maintain the diversity of the population. In this mechanism, individuals further from the best individual have larger possibilities to be selected in the mutation operator. The modified DE is evaluated by solving 6 benchmark functions, and the performance is compared with classic DEs. The results demonstrate that the modified DE has better global search ability and higher computation efficiency. Furthermore, the optimization results of catalytic naphtha reforming process indicate that the proposed algorithm has the ability of locating the optimal operating points, in which the aromatics yield is improved, while energy consumption is reduced. Meanwhile, the optimal operating points and results are discussed at the end of the article.