| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 713325 | IFAC Proceedings Volumes | 2013 | 6 Pages |

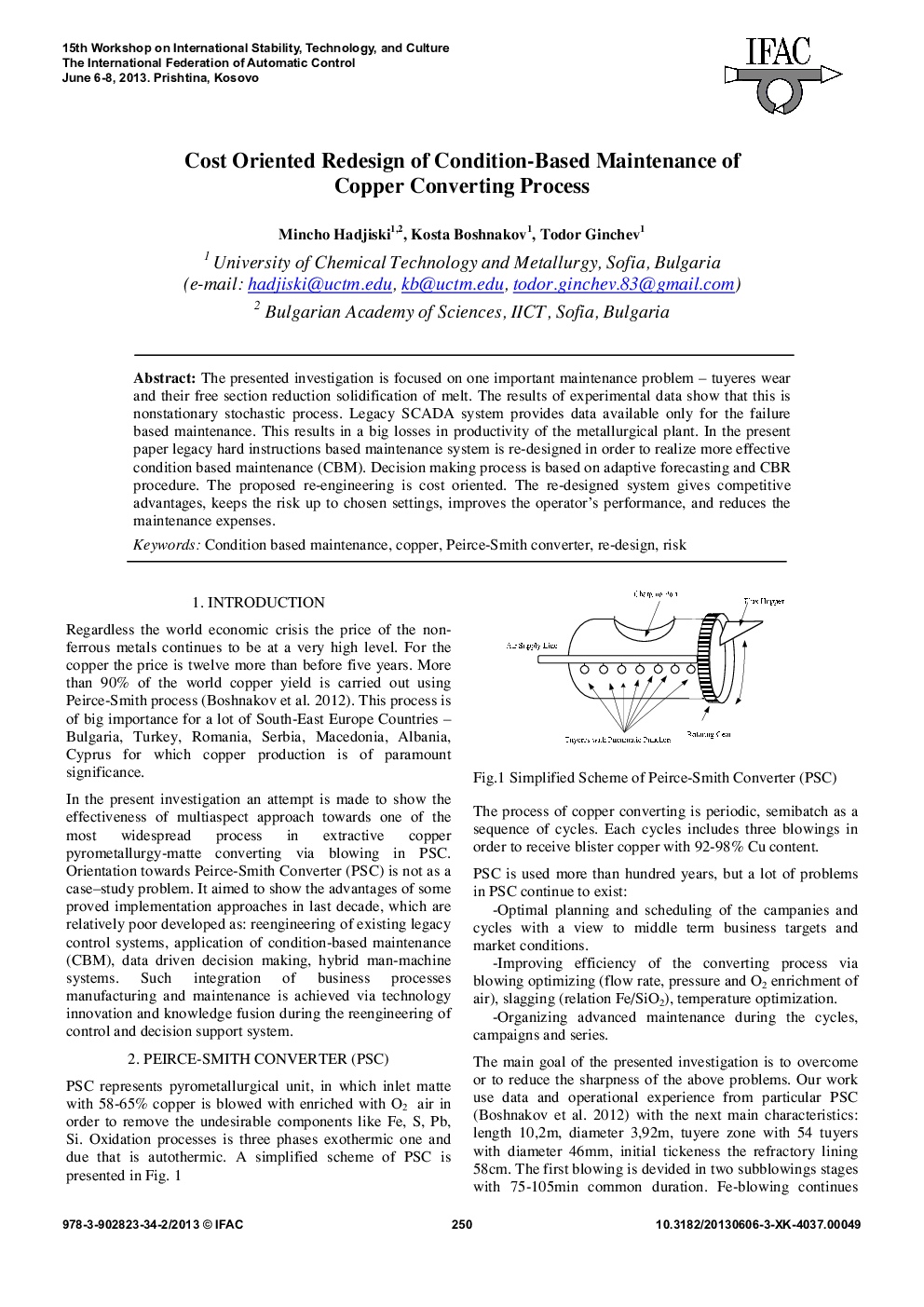

The presented investigation is focused on one important maintenance problem – tuyeres wear and their free section reduction solidification of melt. The results of experimental data show that this is nonstationary stochastic process. Legacy SCADA system provides data available only for the failure based maintenance. This results in a big losses in productivity of the metallurgical plant. In the present paper legacy hard instructions based maintenance system is re-designed in order to realize more effective condition based maintenance (CBM). Decision making process is based on adaptive forecasting and CBR procedure. The proposed re-engineering is cost oriented. The re-designed system gives competitive advantages, keeps the risk up to chosen settings, improves the operator's performance, and reduces the maintenance expenses.