| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

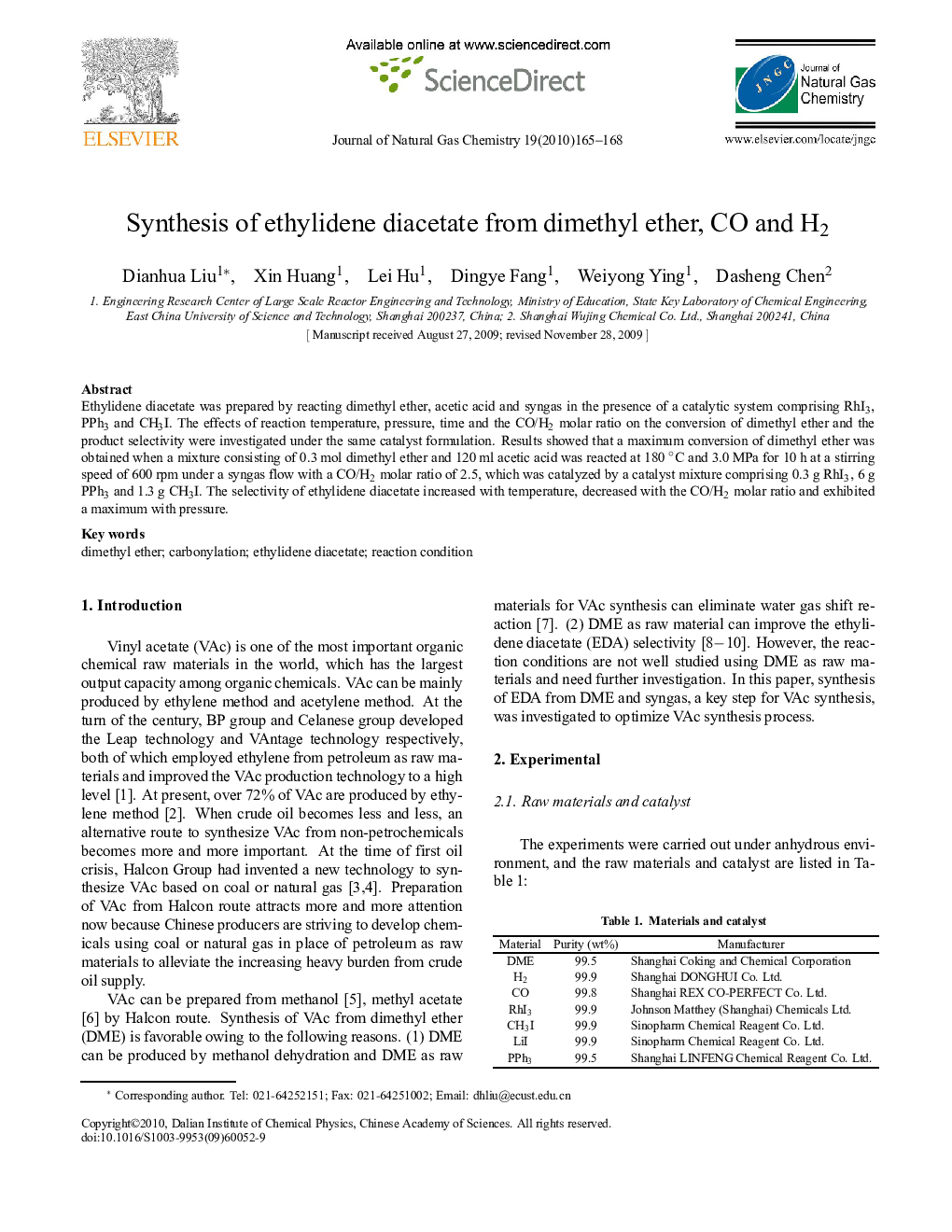

| 71588 | Journal of Natural Gas Chemistry | 2010 | 4 Pages |

Ethylidene diacetate was prepared by reacting dimethyl ether, acetic acid and syngas in the presence of a catalytic system comprising RhI3, PPh3 and CH3I. The effects of reaction temperature, pressure, time and the CO/H2 molar ratio on the conversion of dimethyl ether and the product selectivity were investigated under the same catalyst formulation. Results showed that a maximum conversion of dimethyl ether was obtained when a mixture consisting of 0.3 mol dimethyl ether and 120 ml acetic acid was reacted at 180 °C and 3.0 MPa for 10 h at a stirring speed of 600 rpm under a syngas flow with a CO/H2 molar ratio of 2.5, which was catalyzed by a catalyst mixture comprising 0.3 g RhI3, 6g PPh3 and1.3gCH3I. The selectivity of ethylidene diacetate increased with temperature, decreased with the CO/H2 molar ratio and exhibited a maximum with pressure.