| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 718116 | IFAC Proceedings Volumes | 2010 | 6 Pages |

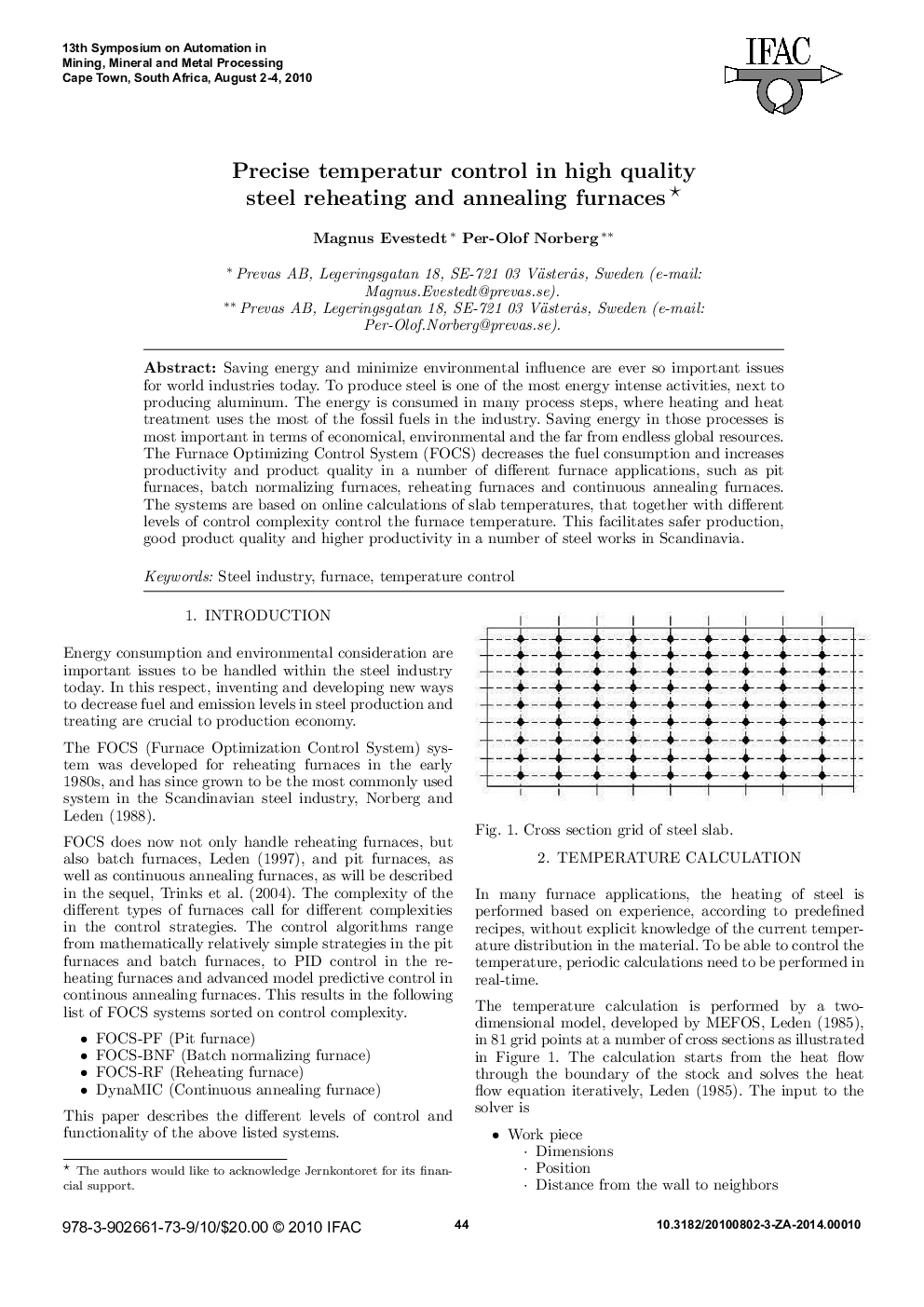

Saving energy and minimize environmental influence are ever so important issues for world industries today. To produce steel is one of the most energy intense activities, next to producing aluminum. The energy is consumed in many process steps, where heating and heat treatment uses the most of the fossil fuels in the industry. Saving energy in those processes is most important in terms of economical, environmental and the far from endless global resources. The Furnace Optimizing Control System (FOCS) decreases the fuel consumption and increases productivity and product quality in a number of different furnace applications, such as pit furnaces, batch normalizing furnaces, reheating furnaces and continuous annealing furnaces. The systems are based on online calculations of slab temperatures, that together with different levels of control complexity control the furnace temperature. This facilitates safer production, good product quality and higher productivity in a number of steel works in Scandinavia.