| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 720817 | IFAC Proceedings Volumes | 2009 | 6 Pages |

Abstract

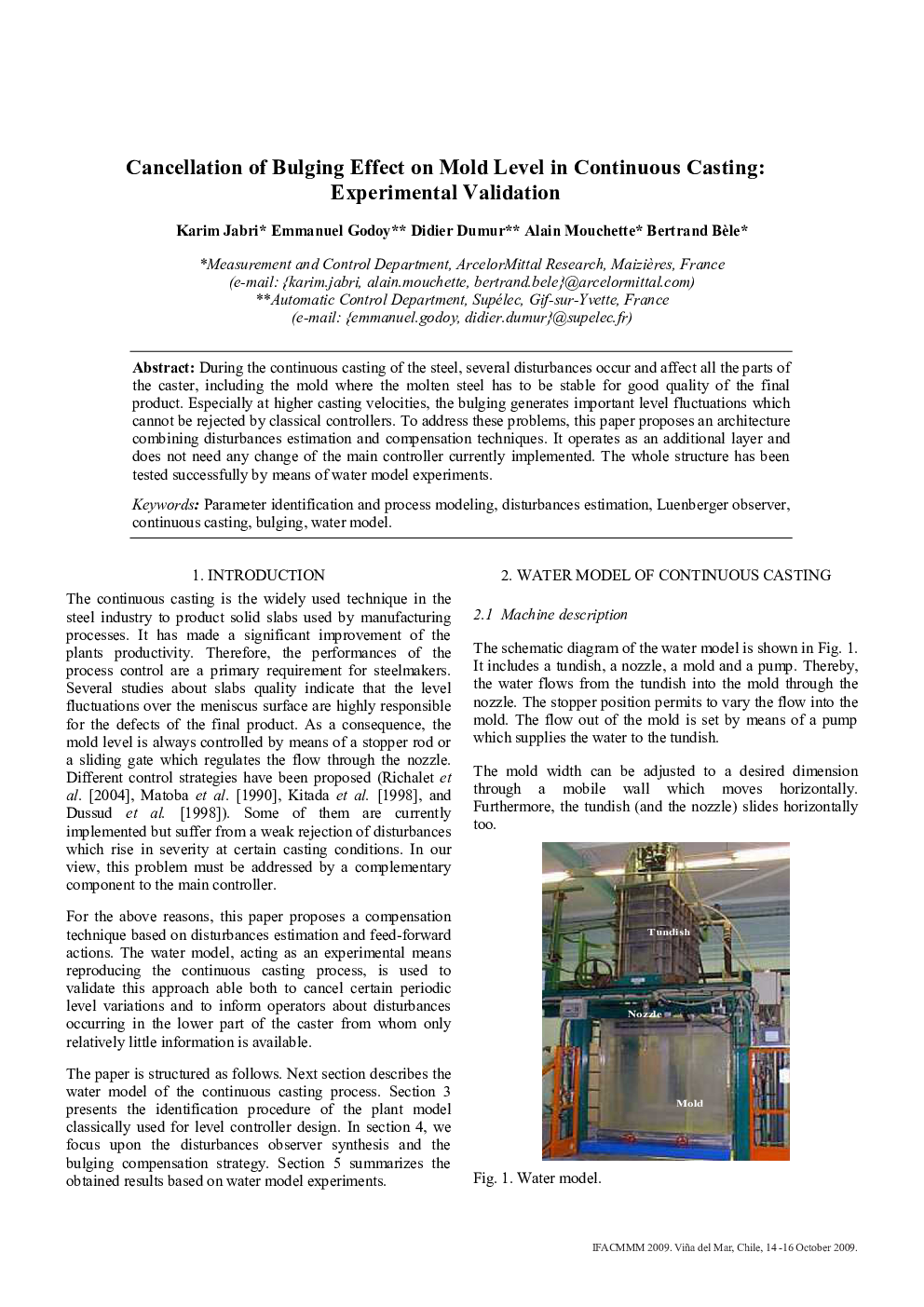

During the continuous casting of the steel, several disturbances occur and affect all the parts of the caster, including the mold where the molten steel has to be stable for good quality of the final product. Especially at higher casting velocities, the bulging generates important level fluctuations which cannot be rejected by classical controllers. To address these problems, this paper proposes an architecture combining disturbances estimation and compensation techniques. It operates as an additional layer and does not need any change of the main controller currently implemented. The whole structure has been tested successfully by means of water model experiments.

Related Topics

Physical Sciences and Engineering

Engineering

Computational Mechanics