| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 733548 | Optics & Laser Technology | 2014 | 11 Pages |

•Automatic detection for micro-weld joint by magneto-optical imaging is studied.•Characteristic of magneto-optical image related to actual weld joint position is investigated.•The influences of different magnetic field intensity and different welding speeds on the detecting weld joint position are studied.

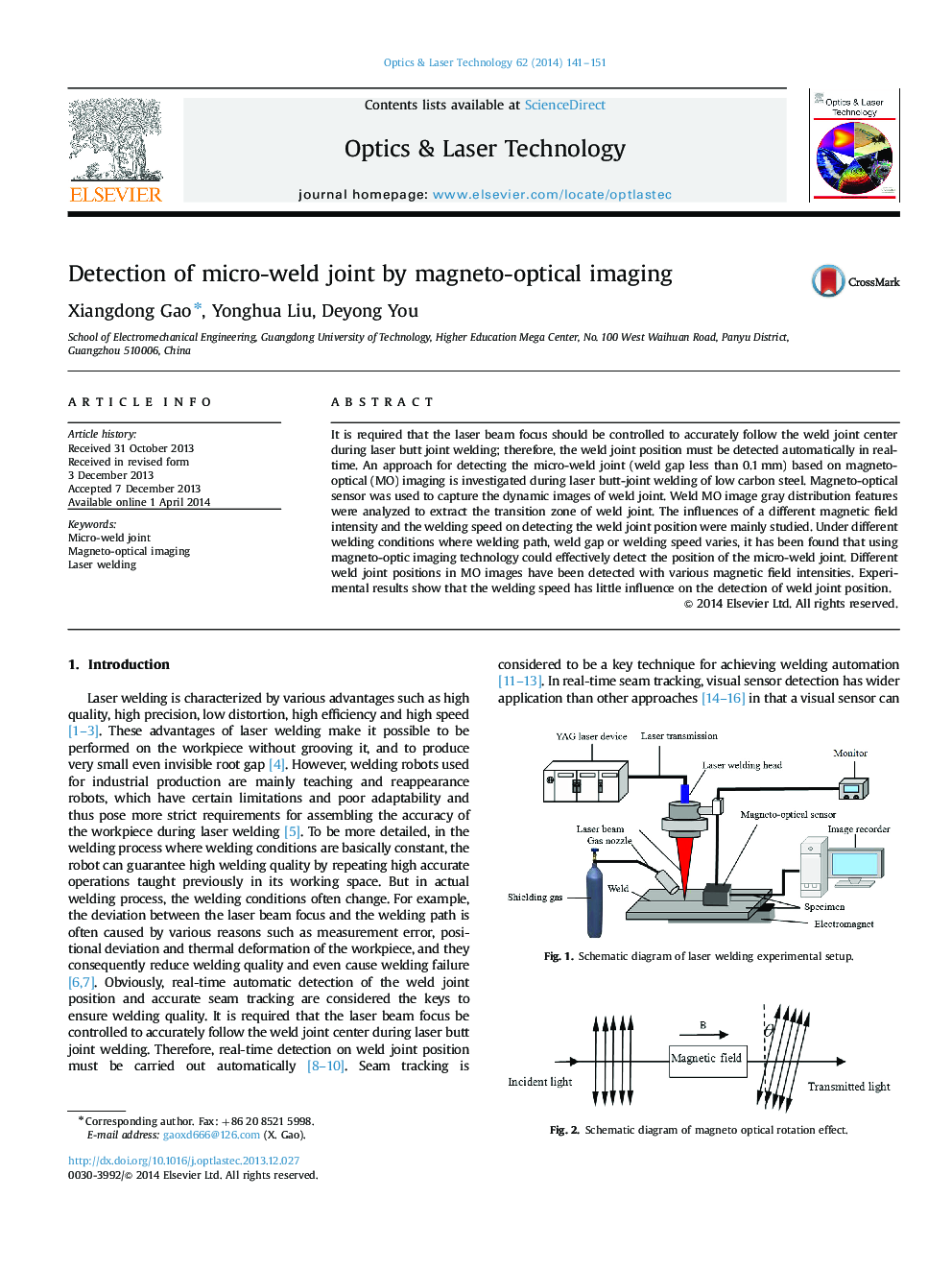

It is required that the laser beam focus should be controlled to accurately follow the weld joint center during laser butt joint welding; therefore, the weld joint position must be detected automatically in real-time. An approach for detecting the micro-weld joint (weld gap less than 0.1 mm) based on magneto-optical (MO) imaging is investigated during laser butt-joint welding of low carbon steel. Magneto-optical sensor was used to capture the dynamic images of weld joint. Weld MO image gray distribution features were analyzed to extract the transition zone of weld joint. The influences of a different magnetic field intensity and the welding speed on detecting the weld joint position were mainly studied. Under different welding conditions where welding path, weld gap or welding speed varies, it has been found that using magneto-optic imaging technology could effectively detect the position of the micro-weld joint. Different weld joint positions in MO images have been detected with various magnetic field intensities. Experimental results show that the welding speed has little influence on the detection of weld joint position.