| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 775571 | Extreme Mechanics Letters | 2015 | 7 Pages |

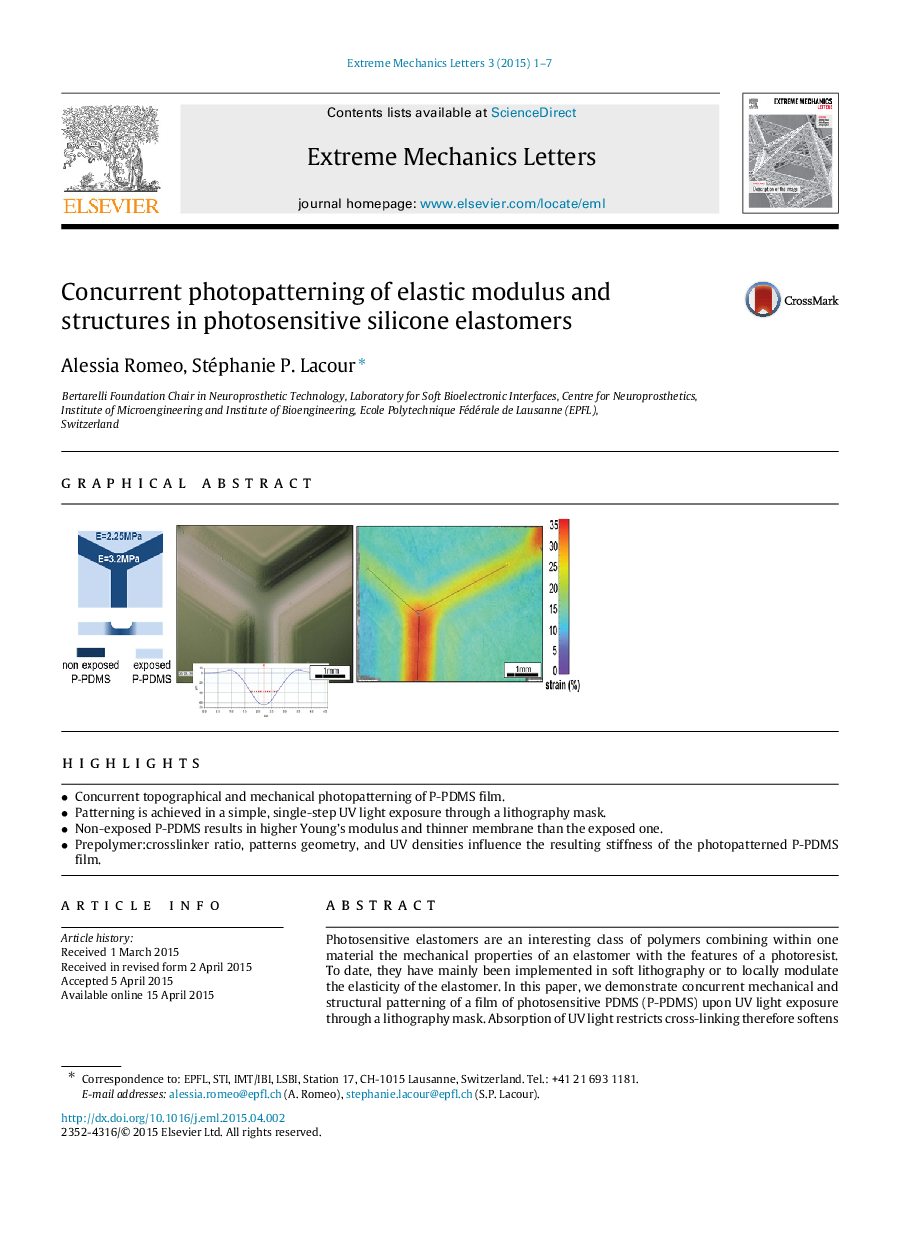

•Concurrent topographical and mechanical photopatterning of P-PDMS film.•Patterning is achieved in a simple, single-step UV light exposure through a lithography mask.•Non-exposed P-PDMS results in higher Young’s modulus and thinner membrane than the exposed one.•Prepolymer:crosslinker ratio, patterns geometry, and UV densities influence the resulting stiffness of the photopatterned P-PDMS film.

Photosensitive elastomers are an interesting class of polymers combining within one material the mechanical properties of an elastomer with the features of a photoresist. To date, they have mainly been implemented in soft lithography or to locally modulate the elasticity of the elastomer. In this paper, we demonstrate concurrent mechanical and structural patterning of a film of photosensitive PDMS (P-PDMS) upon UV light exposure through a lithography mask. Absorption of UV light restricts cross-linking therefore softens the elastomer, but also induces distinct lateral material transfer and structural shrinking of the non-exposed elastomer. P-PDMS microchannels of sub-millimeter cross-section and millimeter length, and patterned Young’s moduli were reliably prepared with this single step process. This combination of properties presents a rapid prototyping approach for soft MEMS, microfluidics and stretchable electronics.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide