| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 785397 | International Journal of Pressure Vessels and Piping | 2013 | 10 Pages |

•3D FEM was used to analyze the welding distortion on two different sequences.•Simulation results were validated with experiments using automated welding system.•Simulation results and experiments showed acceptable accuracy.•Welding sequence “outside–inside” showed less distortion than “inside–outside”.

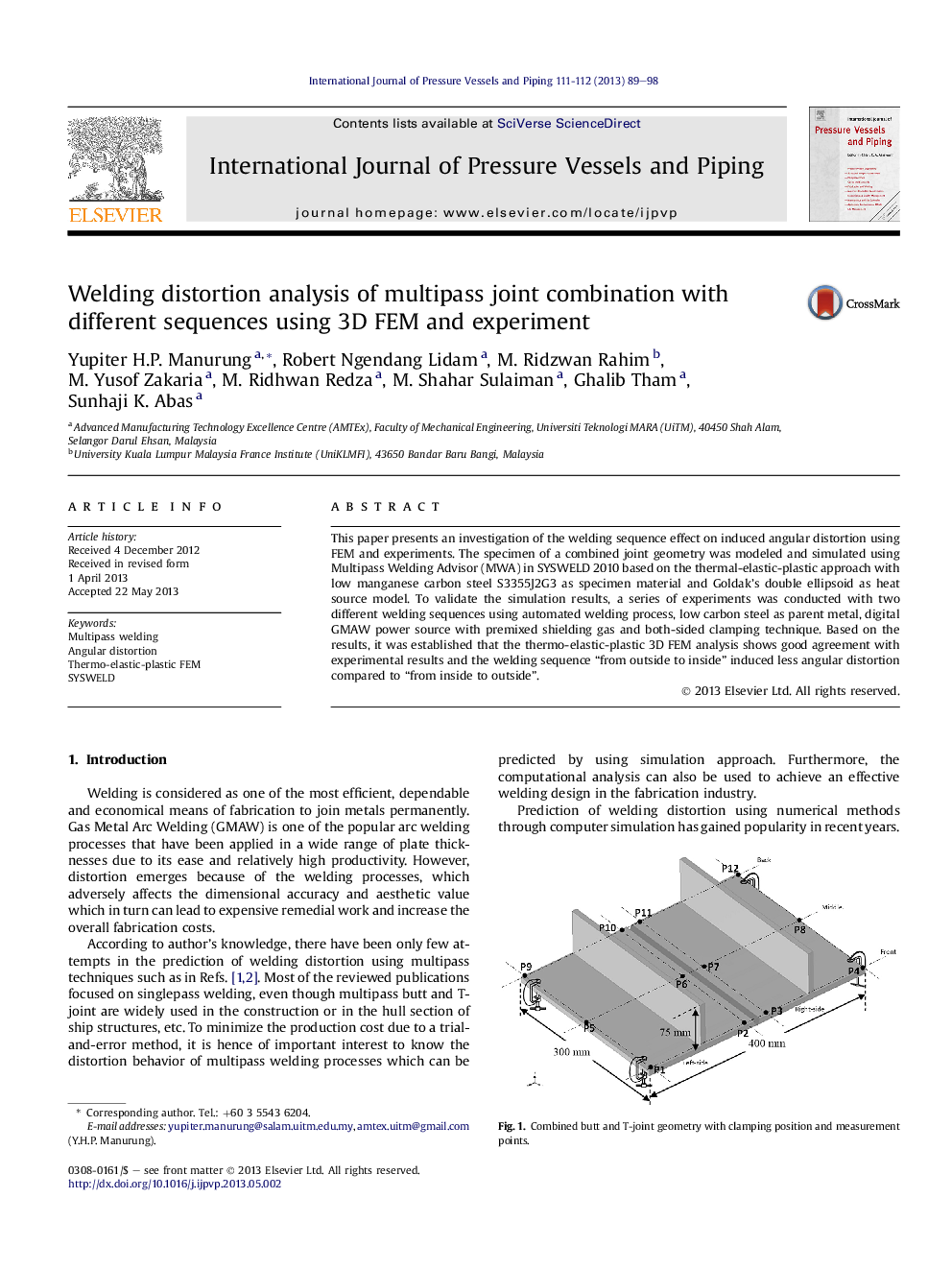

This paper presents an investigation of the welding sequence effect on induced angular distortion using FEM and experiments. The specimen of a combined joint geometry was modeled and simulated using Multipass Welding Advisor (MWA) in SYSWELD 2010 based on the thermal-elastic-plastic approach with low manganese carbon steel S3355J2G3 as specimen material and Goldak's double ellipsoid as heat source model. To validate the simulation results, a series of experiments was conducted with two different welding sequences using automated welding process, low carbon steel as parent metal, digital GMAW power source with premixed shielding gas and both-sided clamping technique. Based on the results, it was established that the thermo-elastic-plastic 3D FEM analysis shows good agreement with experimental results and the welding sequence “from outside to inside” induced less angular distortion compared to “from inside to outside”.