| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 7970424 | Materials Characterization | 2015 | 10 Pages |

Abstract

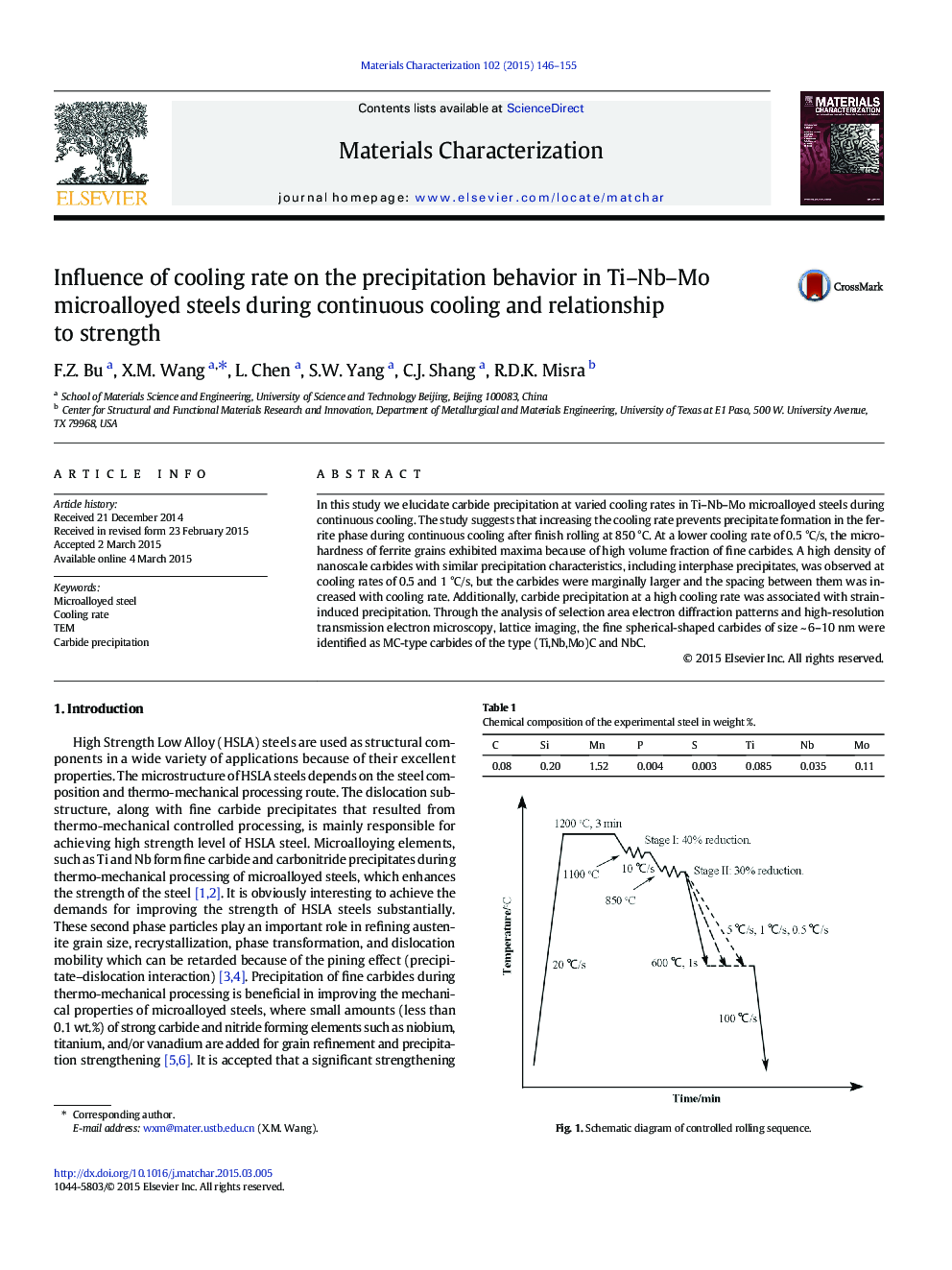

In this study we elucidate carbide precipitation at varied cooling rates in Ti-Nb-Mo microalloyed steels during continuous cooling. The study suggests that increasing the cooling rate prevents precipitate formation in the ferrite phase during continuous cooling after finish rolling at 850 °C. At a lower cooling rate of 0.5 °C/s, the microhardness of ferrite grains exhibited maxima because of high volume fraction of fine carbides. A high density of nanoscale carbides with similar precipitation characteristics, including interphase precipitates, was observed at cooling rates of 0.5 and 1 °C/s, but the carbides were marginally larger and the spacing between them was increased with cooling rate. Additionally, carbide precipitation at a high cooling rate was associated with strain-induced precipitation. Through the analysis of selection area electron diffraction patterns and high-resolution transmission electron microscopy, lattice imaging, the fine spherical-shaped carbides of size ~ 6-10 nm were identified as MC-type carbides of the type (Ti,Nb,Mo)C and NbC.

Related Topics

Physical Sciences and Engineering

Materials Science

Materials Science (General)

Authors

F.Z. Bu, X.M. Wang, L. Chen, S.W. Yang, C.J. Shang, R.D.K. Misra,