| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 8038598 | CIRP Annals - Manufacturing Technology | 2018 | 4 Pages |

Abstract

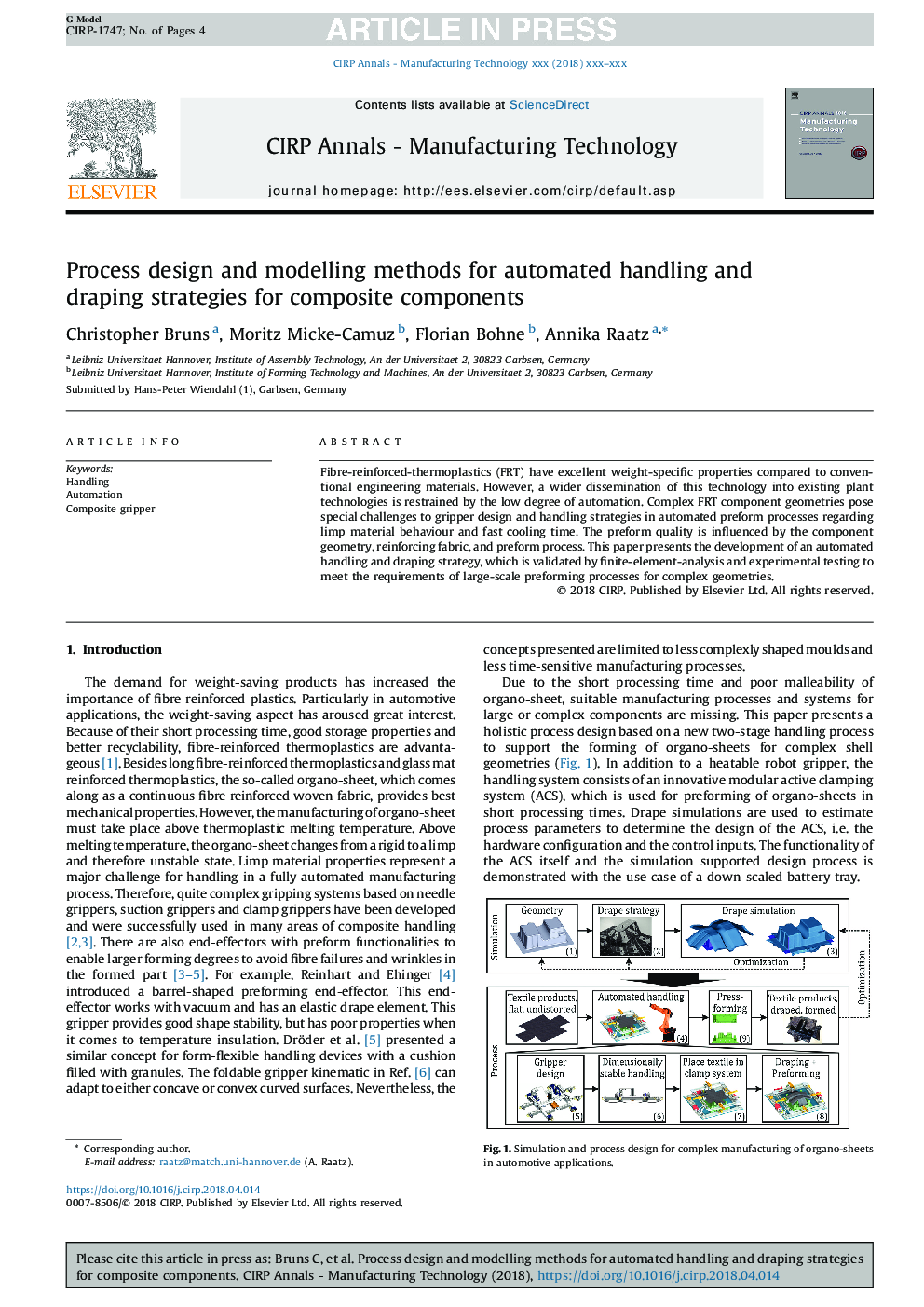

Fibre-reinforced-thermoplastics (FRT) have excellent weight-specific properties compared to conventional engineering materials. However, a wider dissemination of this technology into existing plant technologies is restrained by the low degree of automation. Complex FRT component geometries pose special challenges to gripper design and handling strategies in automated preform processes regarding limp material behaviour and fast cooling time. The preform quality is influenced by the component geometry, reinforcing fabric, and preform process. This paper presents the development of an automated handling and draping strategy, which is validated by finite-element-analysis and experimental testing to meet the requirements of large-scale preforming processes for complex geometries.

Keywords

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

Christopher Bruns, Moritz Micke-Camuz, Florian Bohne, Annika Raatz,