| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 8038664 | CIRP Annals - Manufacturing Technology | 2018 | 4 Pages |

Abstract

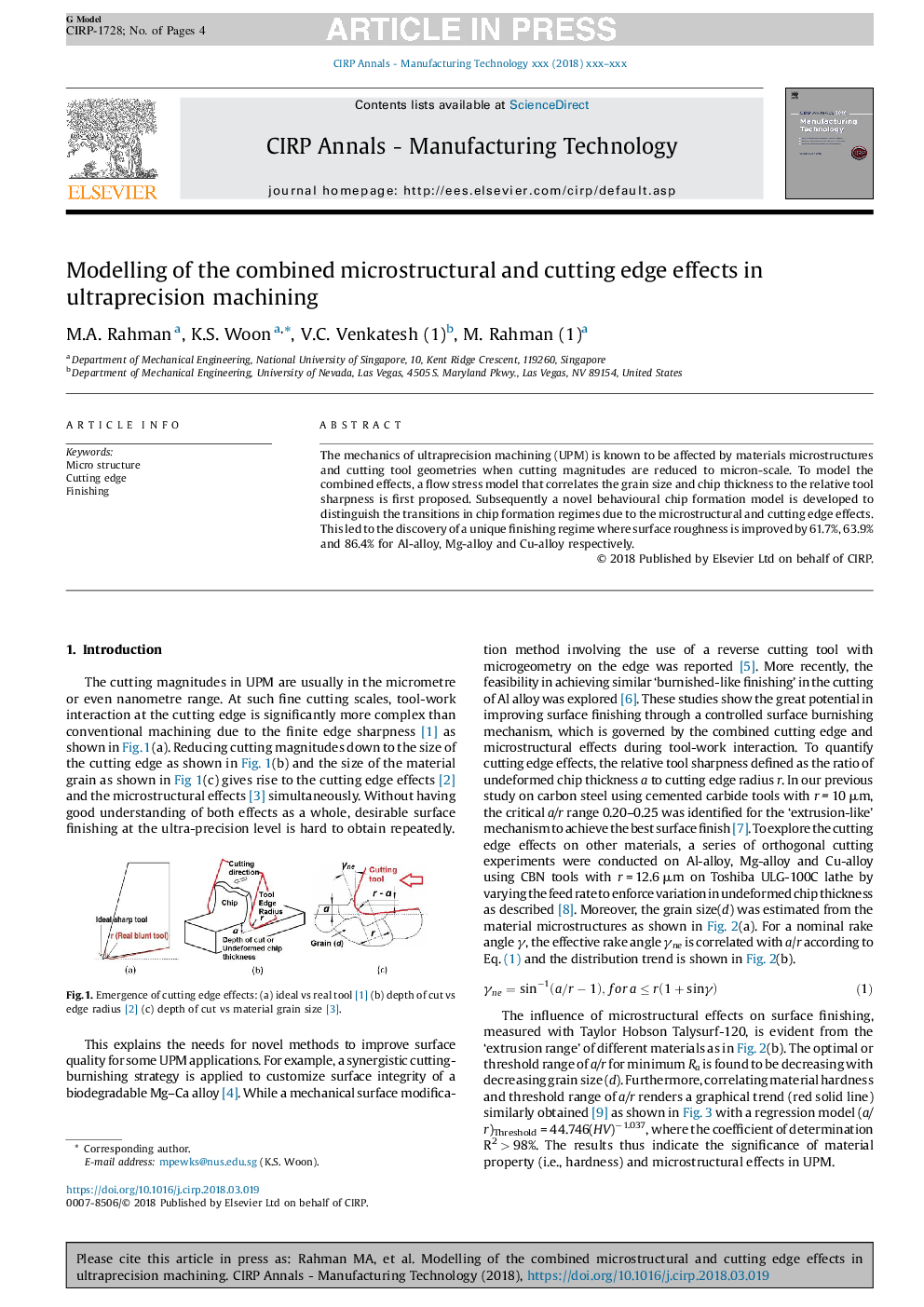

The mechanics of ultraprecision machining (UPM) is known to be affected by materials microstructures and cutting tool geometries when cutting magnitudes are reduced to micron-scale. To model the combined effects, a flow stress model that correlates the grain size and chip thickness to the relative tool sharpness is first proposed. Subsequently a novel behavioural chip formation model is developed to distinguish the transitions in chip formation regimes due to the microstructural and cutting edge effects. This led to the discovery of a unique finishing regime where surface roughness is improved by 61.7%, 63.9% and 86.4% for Al-alloy, Mg-alloy and Cu-alloy respectively.

Keywords

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

M.A. Rahman, K.S. Woon, V.C. Venkatesh, M. Rahman,