| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 8038707 | CIRP Annals - Manufacturing Technology | 2018 | 4 Pages |

Abstract

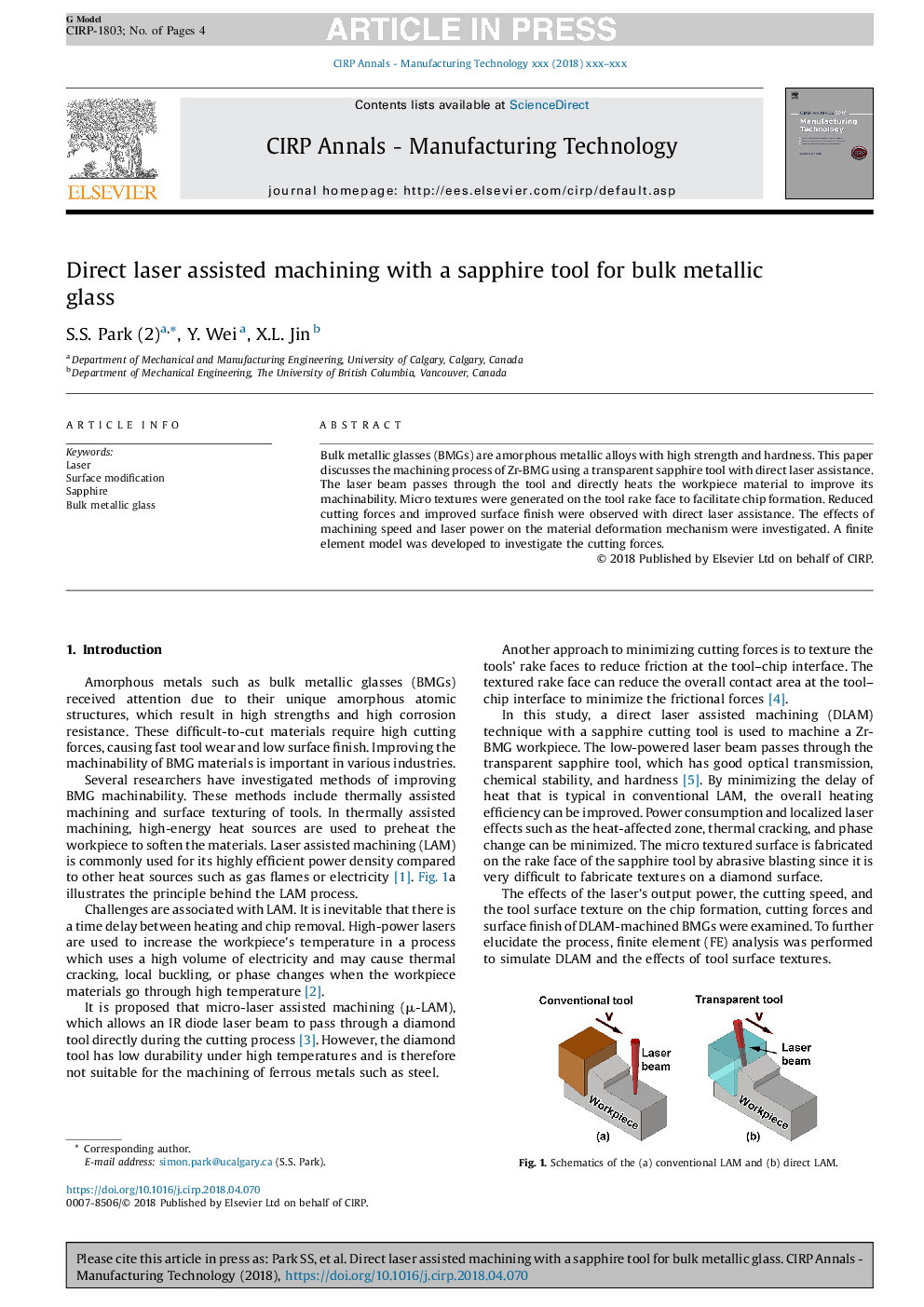

Bulk metallic glasses (BMGs) are amorphous metallic alloys with high strength and hardness. This paper discusses the machining process of Zr-BMG using a transparent sapphire tool with direct laser assistance. The laser beam passes through the tool and directly heats the workpiece material to improve its machinability. Micro textures were generated on the tool rake face to facilitate chip formation. Reduced cutting forces and improved surface finish were observed with direct laser assistance. The effects of machining speed and laser power on the material deformation mechanism were investigated. A finite element model was developed to investigate the cutting forces.

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

S.S. Park, Y. Wei, X.L. Jin,