| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 8038771 | CIRP Annals - Manufacturing Technology | 2018 | 4 Pages |

Abstract

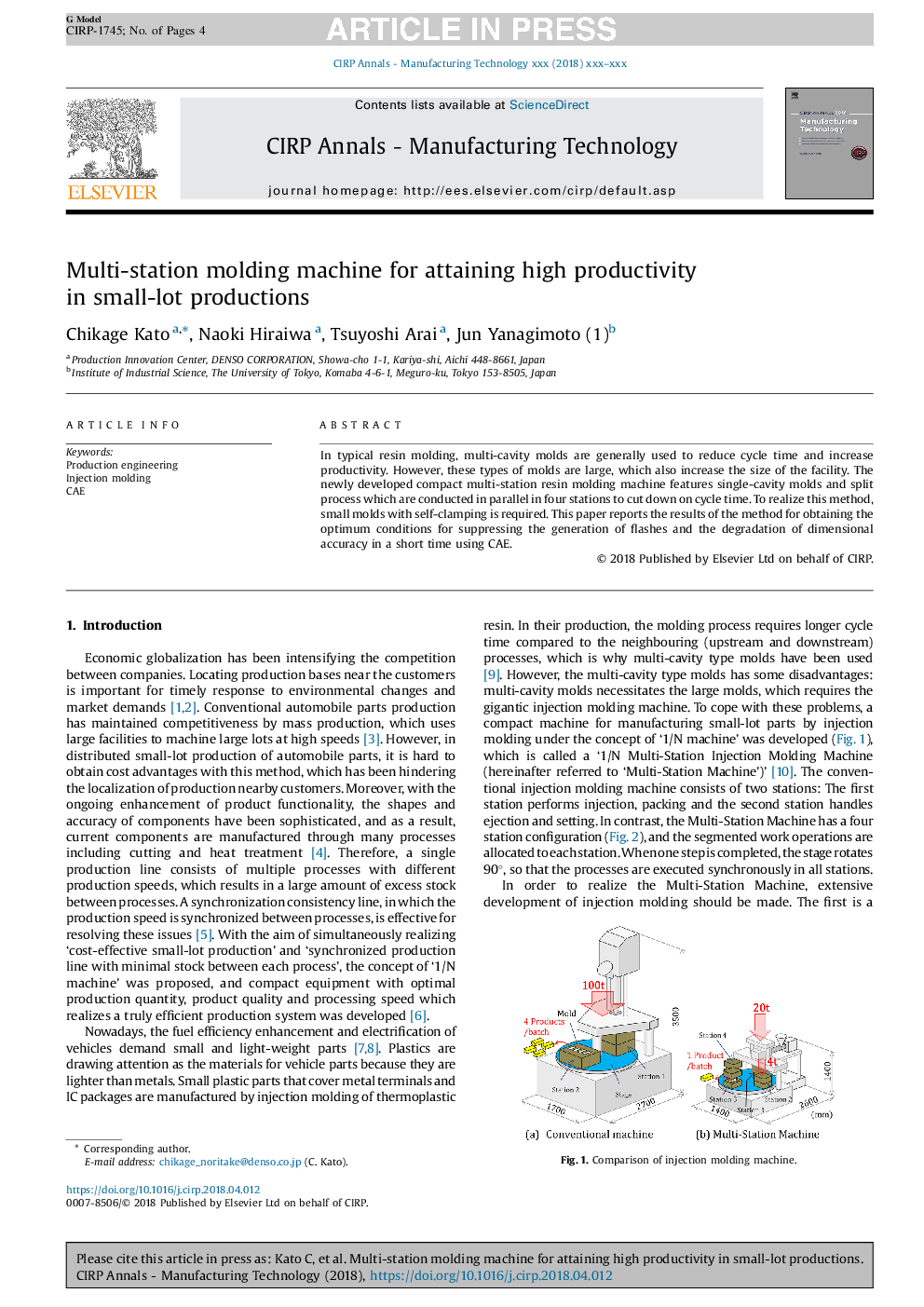

In typical resin molding, multi-cavity molds are generally used to reduce cycle time and increase productivity. However, these types of molds are large, which also increase the size of the facility. The newly developed compact multi-station resin molding machine features single-cavity molds and split process which are conducted in parallel in four stations to cut down on cycle time. To realize this method, small molds with self-clamping is required. This paper reports the results of the method for obtaining the optimum conditions for suppressing the generation of flashes and the degradation of dimensional accuracy in a short time using CAE.

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

Chikage Kato, Naoki Hiraiwa, Tsuyoshi Arai, Jun Yanagimoto,