| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 8038779 | CIRP Annals - Manufacturing Technology | 2018 | 4 Pages |

Abstract

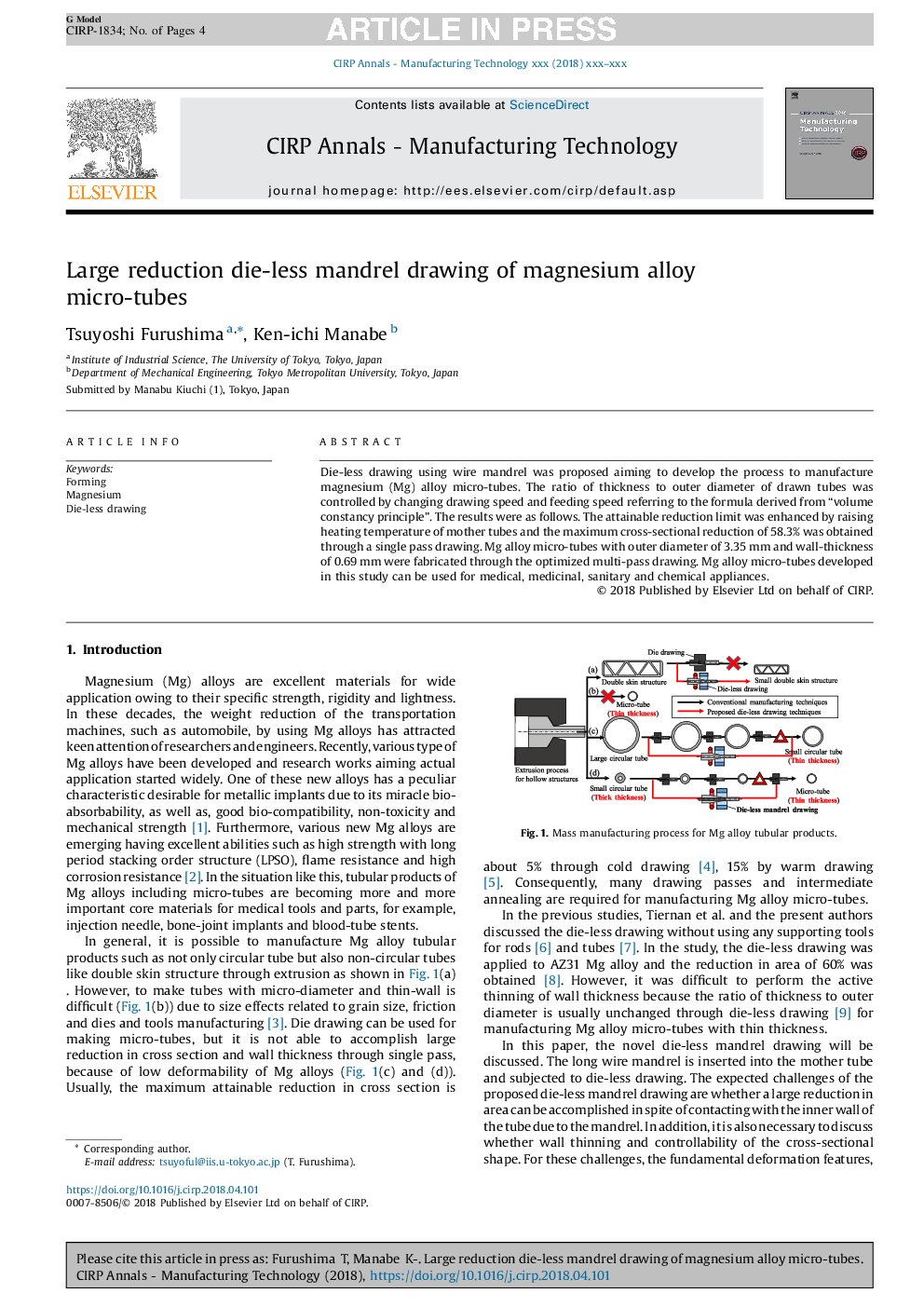

Die-less drawing using wire mandrel was proposed aiming to develop the process to manufacture magnesium (Mg) alloy micro-tubes. The ratio of thickness to outer diameter of drawn tubes was controlled by changing drawing speed and feeding speed referring to the formula derived from “volume constancy principle”. The results were as follows. The attainable reduction limit was enhanced by raising heating temperature of mother tubes and the maximum cross-sectional reduction of 58.3% was obtained through a single pass drawing. Mg alloy micro-tubes with outer diameter of 3.35Â mm and wall-thickness of 0.69Â mm were fabricated through the optimized multi-pass drawing. Mg alloy micro-tubes developed in this study can be used for medical, medicinal, sanitary and chemical appliances.

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

Tsuyoshi Furushima, Ken-ichi Manabe,