| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 827683 | Materials & Design | 2016 | 7 Pages |

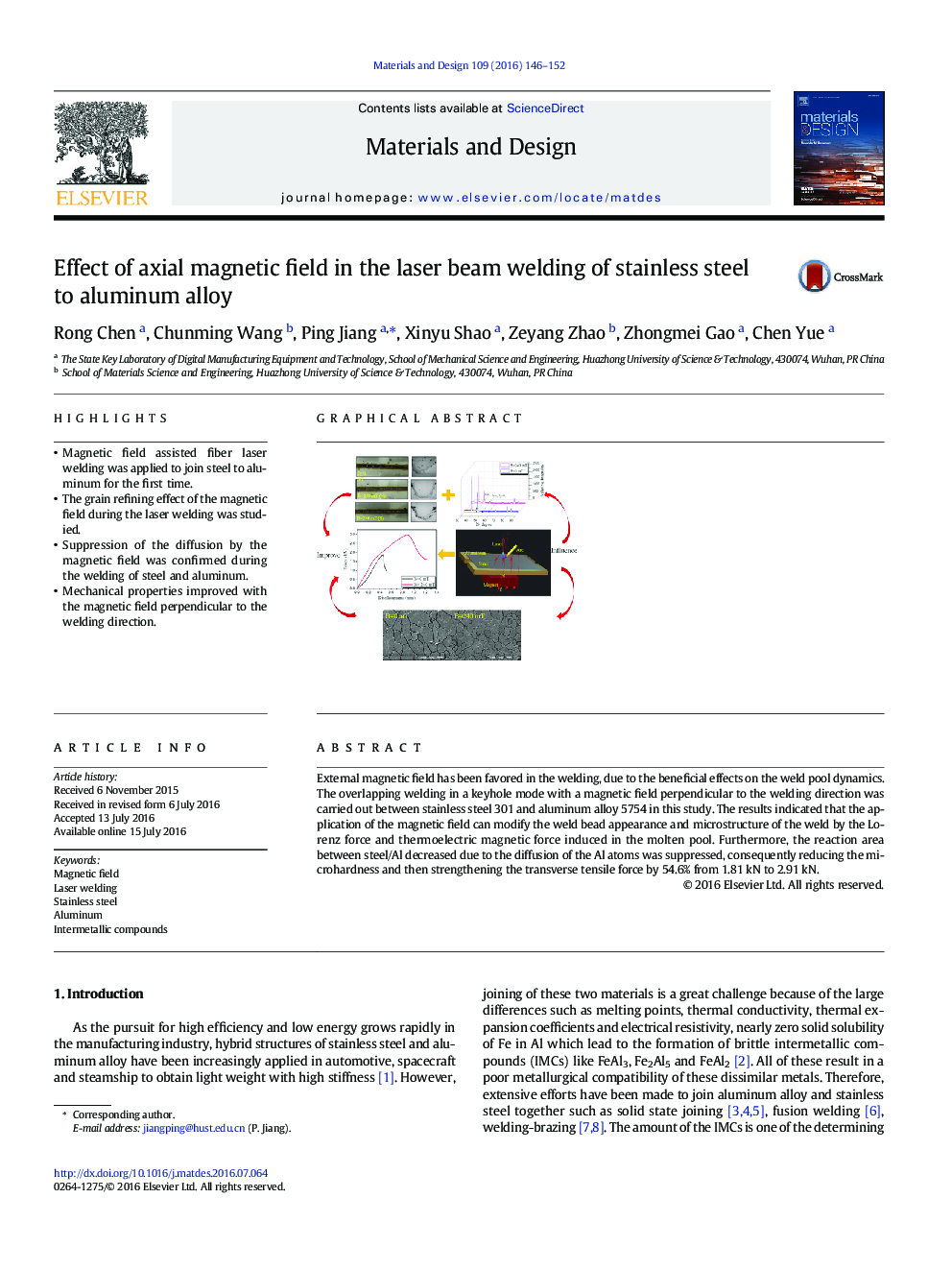

•Magnetic field assisted fiber laser welding was applied to join steel to aluminum for the first time.•The grain refining effect of the magnetic field during the laser welding was studied.•Suppression of the diffusion by the magnetic field was confirmed during the welding of steel and aluminum.•Mechanical properties improved with the magnetic field perpendicular to the welding direction.

External magnetic field has been favored in the welding, due to the beneficial effects on the weld pool dynamics. The overlapping welding in a keyhole mode with a magnetic field perpendicular to the welding direction was carried out between stainless steel 301 and aluminum alloy 5754 in this study. The results indicated that the application of the magnetic field can modify the weld bead appearance and microstructure of the weld by the Lorenz force and thermoelectric magnetic force induced in the molten pool. Furthermore, the reaction area between steel/Al decreased due to the diffusion of the Al atoms was suppressed, consequently reducing the microhardness and then strengthening the transverse tensile force by 54.6% from 1.81 kN to 2.91 kN.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide