| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 827742 | Materials & Design | 2016 | 9 Pages |

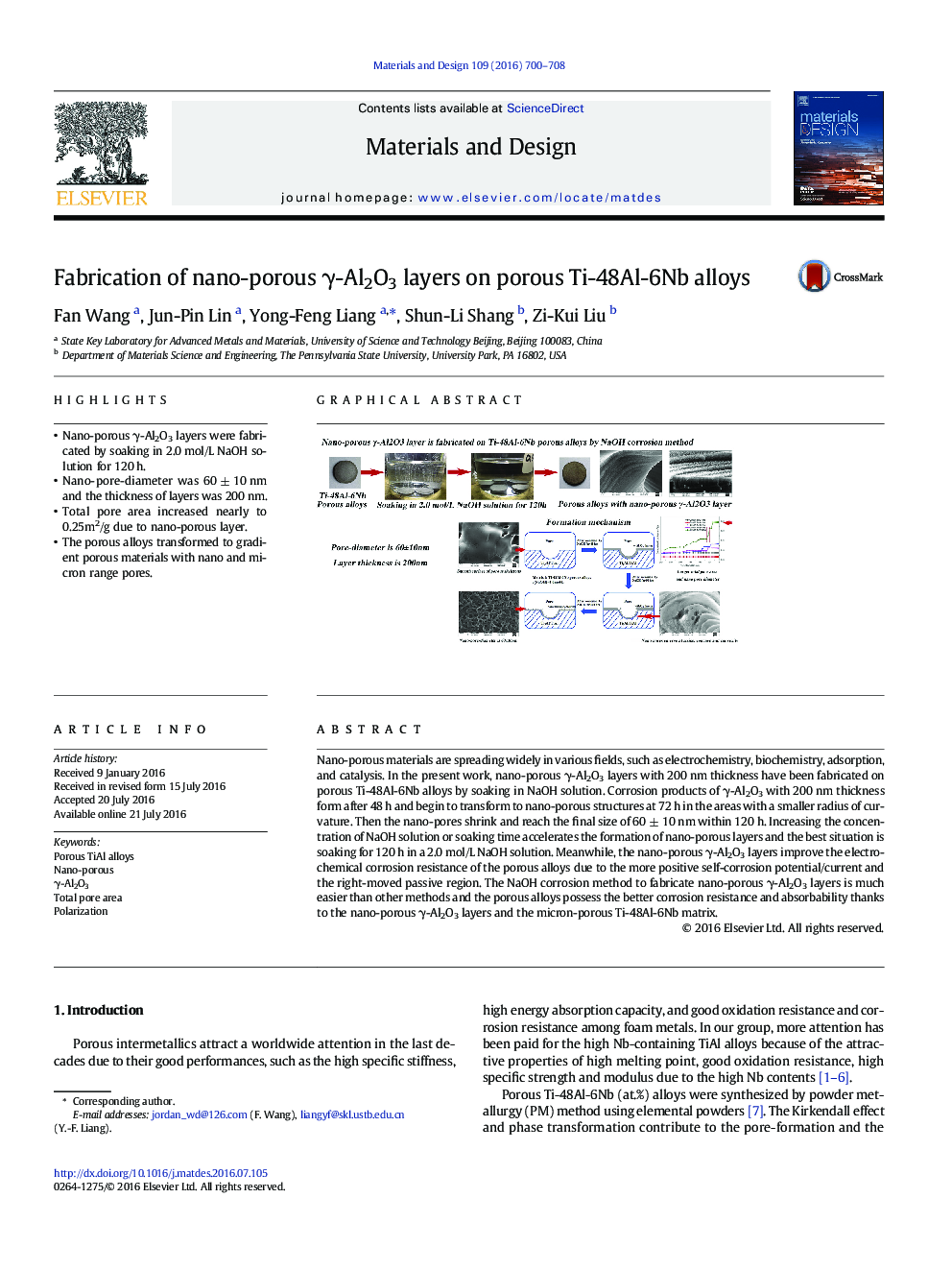

•Nano-porous γ-Al2O3 layers were fabricated by soaking in 2.0 mol/L NaOH solution for 120 h.•Nano-pore-diameter was 60 ± 10 nm and the thickness of layers was 200 nm.•Total pore area increased nearly to 0.25m2/g due to nano-porous layer.•The porous alloys transformed to gradient porous materials with nano and micron range pores.

Nano-porous materials are spreading widely in various fields, such as electrochemistry, biochemistry, adsorption, and catalysis. In the present work, nano-porous γ-Al2O3 layers with 200 nm thickness have been fabricated on porous Ti-48Al-6Nb alloys by soaking in NaOH solution. Corrosion products of γ-Al2O3 with 200 nm thickness form after 48 h and begin to transform to nano-porous structures at 72 h in the areas with a smaller radius of curvature. Then the nano-pores shrink and reach the final size of 60 ± 10 nm within 120 h. Increasing the concentration of NaOH solution or soaking time accelerates the formation of nano-porous layers and the best situation is soaking for 120 h in a 2.0 mol/L NaOH solution. Meanwhile, the nano-porous γ-Al2O3 layers improve the electrochemical corrosion resistance of the porous alloys due to the more positive self-corrosion potential/current and the right-moved passive region. The NaOH corrosion method to fabricate nano-porous γ-Al2O3 layers is much easier than other methods and the porous alloys possess the better corrosion resistance and absorbability thanks to the nano-porous γ-Al2O3 layers and the micron-porous Ti-48Al-6Nb matrix.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide