| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 865690 | Tsinghua Science & Technology | 2008 | 6 Pages |

Abstract

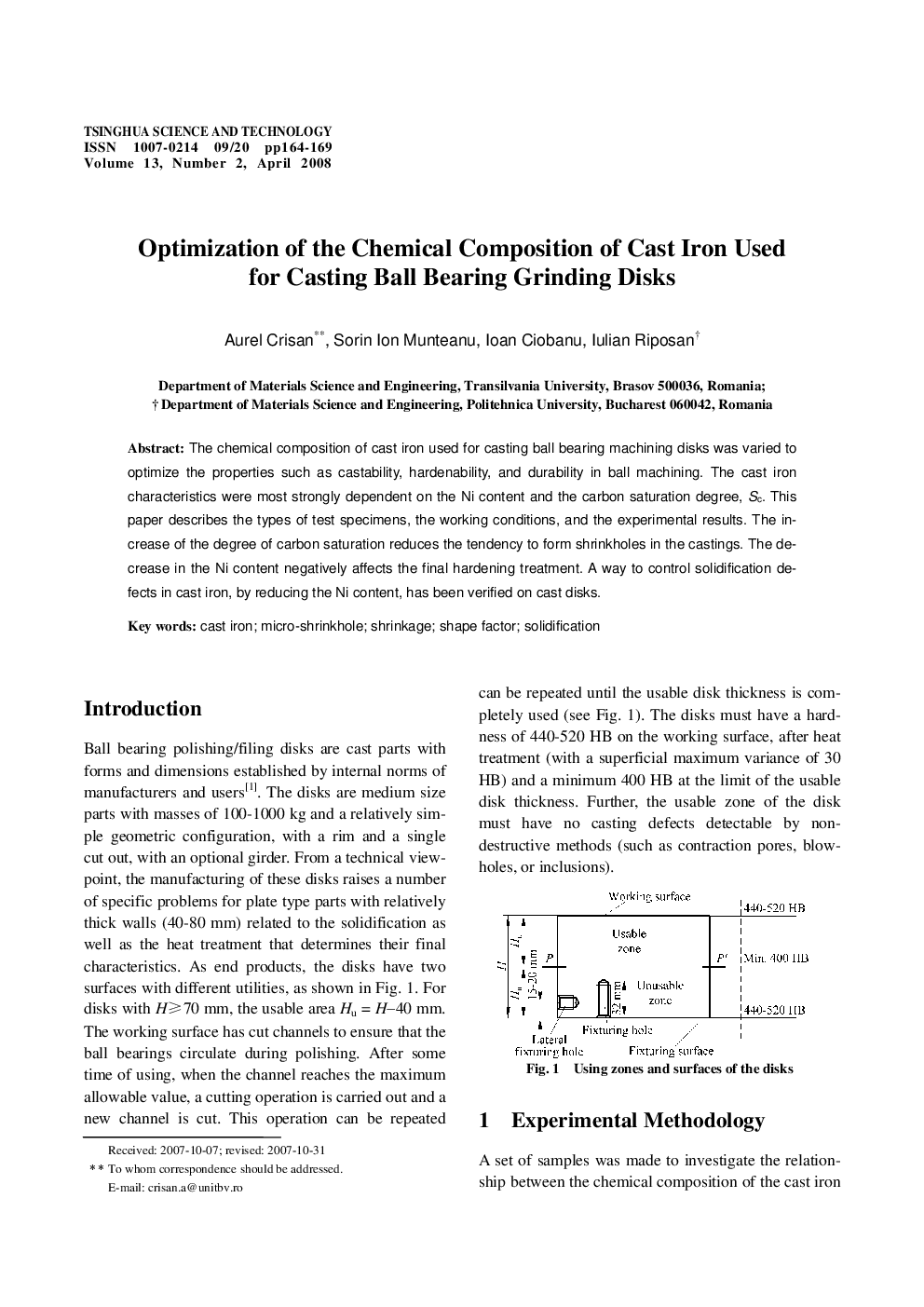

The chemical composition of cast iron used for casting ball bearing machining disks was varied to optimize the properties such as castability, hardenability, and durability in ball machining. The cast iron characteristics were most strongly dependent on the Ni content and the carbon saturation degree, Sc. This paper describes the types of test specimens, the working conditions, and the experimental results. The increase of the degree of carbon saturation reduces the tendency to form shrinkholes in the castings. The decrease in the Ni content negatively affects the final hardening treatment. A way to control solidification defects in cast iron, by reducing the Ni content, has been verified on cast disks.

Related Topics

Physical Sciences and Engineering

Engineering

Engineering (General)

Authors

Aurel Crisan, Sorin Ion Munteanu, Ioan Ciobanu, Iulian Riposan,